Flexible Film Density: Formulas, Tables & Yield

Updated for packaging engineers, buyers, and converters who need quick, dependable numbers for quotations, spec sheets, and line setup.

Executive Summary

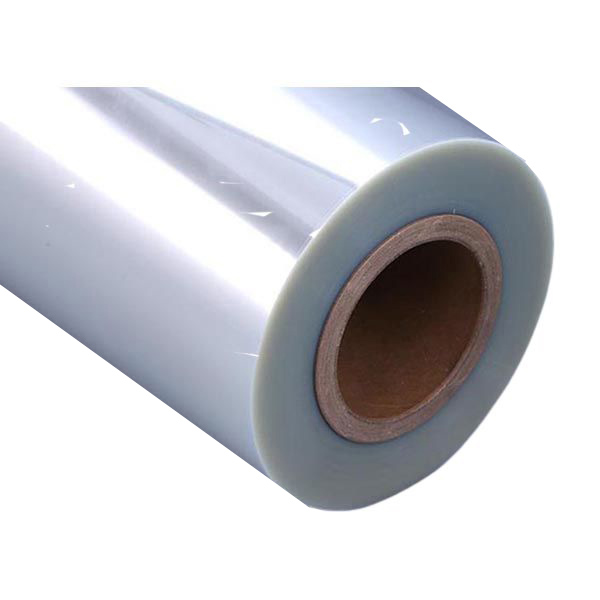

Flexible film density (ρ, g/cm³) links thickness to weight and yield. The rule of thumb you’ll use daily is:

-

GSM (g/m²) = ρ × t(µm)

-

Yield (m²/kg) = 1000 / (ρ × t)

-

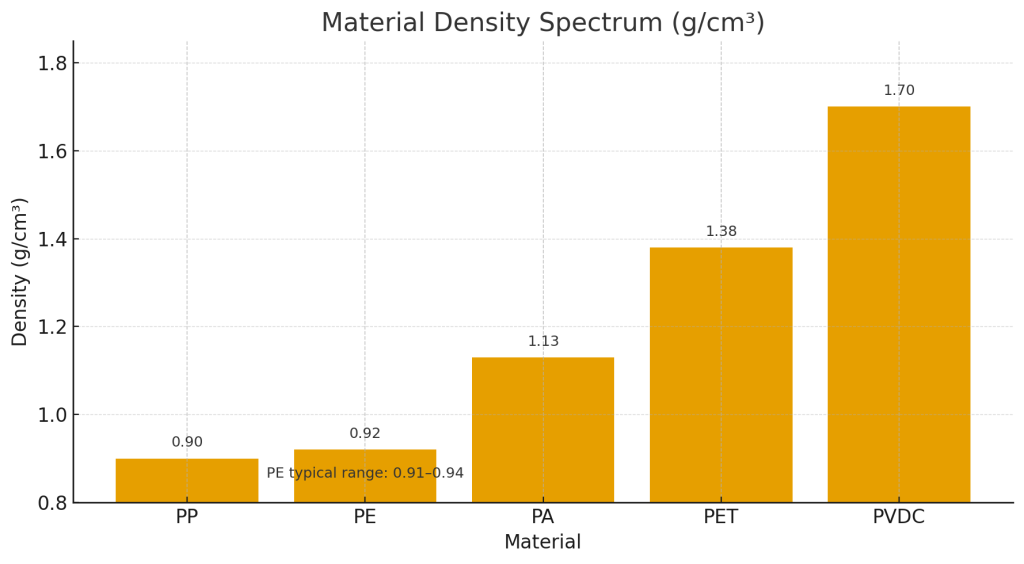

For multilayers, use ρ_avg = (Σ ρᵢ·tᵢ)/(Σ tᵢ) and then apply the same formulas.

These shortcuts let you compare PP, PE, PET, PA and metallized films at a glance, estimate roll weight, and choose structures that hit your performance and recyclability goals.

Alt: Diagram showing GSM=ρ×µm and yield=1000/(ρ×µm) for flexible packaging films.

Alt: Diagram showing GSM=ρ×µm and yield=1000/(ρ×µm) for flexible packaging films.

What Is Film Density and Why It Matters

Density is mass per unit volume. In flexible packaging, it drives:

-

Cost & Yield: At the same micron, a lower-density film delivers more area per kilogram—handy when optimizing material usage.

-

Roll Weight & Logistics: With the right ρ you can forecast roll weights, freight, and changeover frequency.

-

Feel & Stiffness: Higher-density polymers like PET often feel stiffer than PP at the same thickness.

-

Sustainability: Mono-material designs (all-PE or all-PP) rely on density-aware specs to achieve target yield while staying recyclable.

Core Equations (Keep These Handy)

Let density be ρ (g/cm³) and thickness t (µm).

-

Basis weight (GSM):

GSM = ρ × t

Derivation: 1 m² at t µm has volume t cm³; mass = ρ × volume → grams per square meter. -

Yield (area per kg):

m²/kg = 1000 / GSM = 1000 / (ρ × t) -

Roll weight: for roll width W (m) and length L (m)

Mass (kg) = W × L × t × ρ × 0.001

(Add core weight separately.) -

Multilayer average density: for layers i with density ρᵢ and thickness tᵢ (µm)

ρ_avg = (Σ ρᵢ·tᵢ) / (Σ tᵢ)

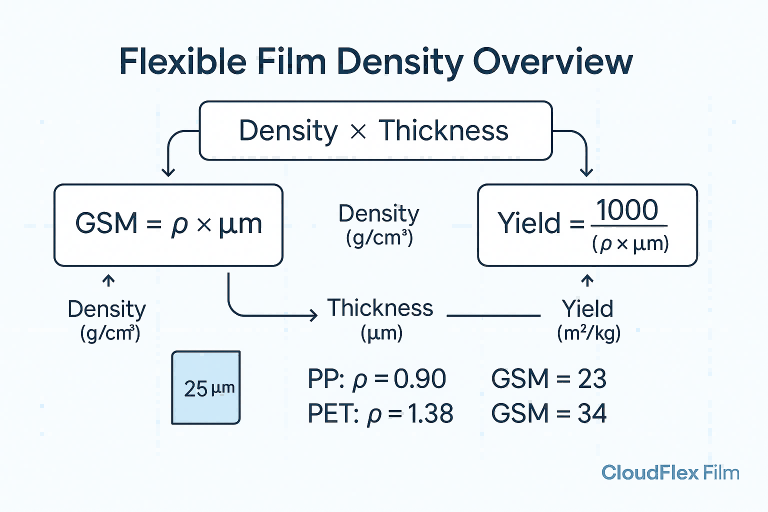

Typical Densities (Reference Values)

These are widely used references; confirm against supplier datasheets for purchasing.

-

PP / BOPP / CPP: ~0.90–0.91 g/cm³

-

PE (LDPE/LLDPE): ~0.91–0.93 g/cm³; HDPE: ~0.94–0.97 g/cm³

-

PET / BOPET: ~1.34–1.40 g/cm³ (often use 1.38)

-

PA (Nylon 6/66): ~1.12–1.15 g/cm³

-

EVOH: ~1.12–1.19 g/cm³ (varies with ethylene content)

-

PVDC: ~1.65–1.75 g/cm³ (usage constrained by regulations/sustainability)

-

Metallized OPP/PET: base density unchanged; aluminum adds ~0.5–1.0 gsm to basis weight.

Alt: Bar chart of typical film densities: PP~0.90, PE~0.91–0.94, PA~1.13, PET~1.38, PVDC~1.7.

Worked Examples (Step by Step)

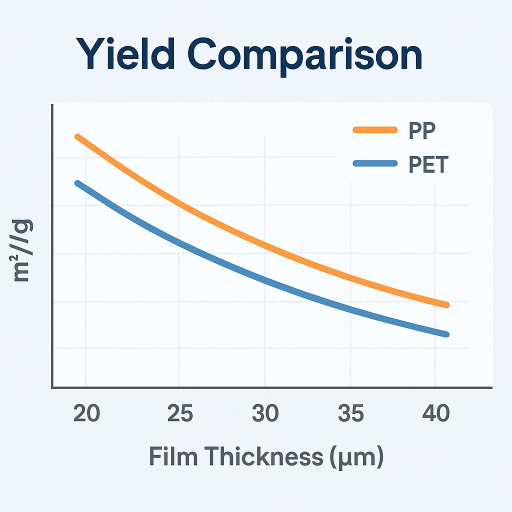

1) Yield at Same Micron: PP vs PET (25 µm)

-

PP: ρ≈0.90 → GSM = 0.90×25 = 22.5 g/m² → Yield = 1000/22.5 ≈ 44.4 m²/kg

-

PET: ρ≈1.38 → GSM = 1.38×25 = 34.5 g/m² → Yield = 1000/34.5 ≈ 29.0 m²/kg

Result: At 25 µm, PP gives ~53% more area per kg than PET.

2) Roll Weight for Lidding Film (PET)

-

Width 0.255 m, Length 3,000 m, Thickness 35 µm, ρ=1.38

-

Mass = 0.255 × 3000 × 35 × 1.38 × 0.001 ≈ 37.1 kg (+ core)

3) Metallized OPP, 20 µm with ~0.8 gsm Al

-

Base GSM = 0.90 × 20 = 18.0 gsm

-

Total GSM ≈ 18.8 gsm → Yield ≈ 1000/18.8 ≈ 53.2 m²/kg

4) Multilayer ρ_avg (CPP/EVOH/CPP)

-

CPP 20 µm (ρ=0.90), EVOH 3 µm (ρ=1.17), CPP 7 µm (ρ=0.90)

-

ρ_avg = (0.90×20 + 1.17×3 + 0.90×7) / (20+3+7)

= (18 + 3.51 + 6.3) / 30 = 0.92 g/cm³ (use this ρ for GSM/Yield)

Alt: Schematic of CPP/EVOH/CPP showing how thickness fractions determine average density.

Alt: Schematic of CPP/EVOH/CPP showing how thickness fractions determine average density.

Quick Reference Table (20 µm)

| Film / Material | ρ (g/cm³) | GSM at 20 µm | Yield m²/kg (20 µm) |

|---|---|---|---|

| PP / BOPP / CPP | 0.90 | 18.0 | 55.6 |

| PE (LD/LL) | 0.92 | 18.4 | 54.3 |

| PET / BOPET | 1.38 | 27.6 | 36.2 |

| PA (Nylon 6) | 1.13 | 22.6 | 44.3 |

| Metallized OPP (base) | 0.90 (+~0.8 gsm) | 18.0 → 18.8 | 55.6 → 53.2 |

Alt: Chart comparing m²/kg of PP vs PET at 20–40 µm thickness.

Density vs. Performance (What Density Does—and Doesn’t—Tell You)

-

Stiffness & Feel: Higher ρ materials (e.g., PET) often feel stiffer at equal microns, but stiffness can also be tuned by thickness and orientation.

-

Sealing Window: Density does not set seal temperature—your seal layer polymer and formulation do.

-

Barrier: Oxygen/moisture barrier stems from polymer chemistry and coatings (metallization, SiOx, EVOH), not density alone.

-

Optics: PET is usually clearer than PP at the same gauge; matte/gloss results from formulation and process (casting/orientation).

-

Machinability: For a given GSM, different ρ–t splits change bend stiffness and slip feel; tune t, slip, and COF to your line.

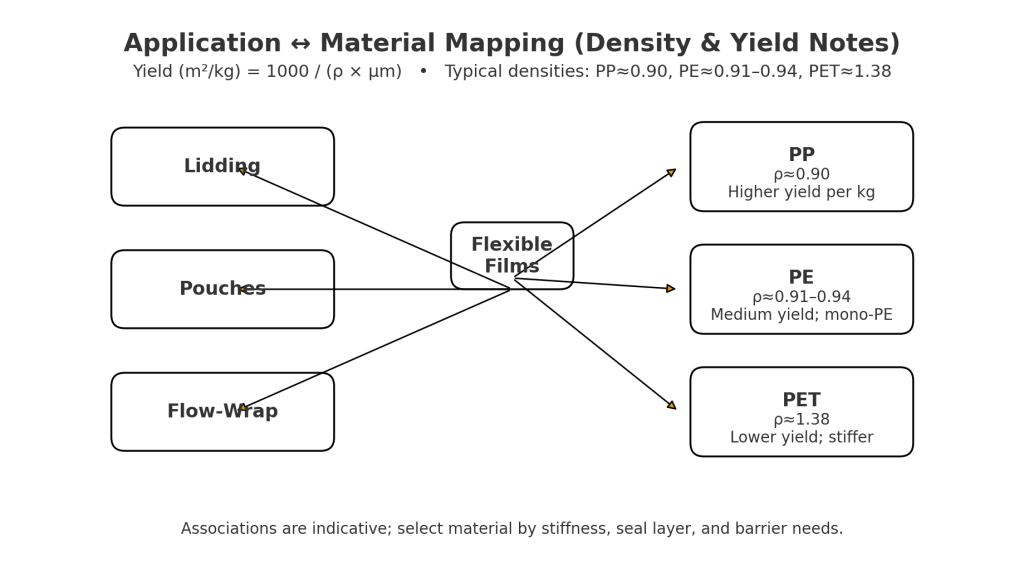

Selection Guide by Application

-

Lidding films (PET/PP peelable, antifog): PET provides stiffness and clarity; PP reduces weight per area. Pick based on tray/bowl material and target peel force.

-

Pouches (mono-PE/PP): For recyclability, stay within one polymer family. Use ρ×µm to hit drop/stack test targets.

-

Flow-wrap for snacks/tissues (BOPP/CPP/PE): Lower ρ (BOPP/CPP) improves yield; add metallization where barrier is needed.

-

Apparel bags (matte CPE): Density near PE; thickness sets hand-feel and haze.

-

Recyclable mono-material: Use ρ_avg to keep specs comparable while remaining in PE or PP streams.

Alt: Map linking lidding, pouches, and flow-wrap to PP/PE/PET with density/yield notes.

FAQ (Structured for Featured Snippets)

Q1. What’s the fastest way to estimate film weight?

A. GSM = ρ × µm. Multiply GSM by area (m²) for grams.

Q2. How do PP and PET compare at the same micron?

A. PP yields more area per kg (lower ρ), while PET offers greater stiffness and heat resistance.

Q3. Does density determine seal temperature?

A. No. Seal layer polymer and formulation control the sealing window.

Q4. How should I count metallization?

A. Add ~0.5–1.0 gsm to the base film’s GSM depending on metal thickness.

Q5. Is density enough to predict barrier?

A. No. Barrier is driven by polymer chemistry and coatings (EVOH, metal, SiOx).

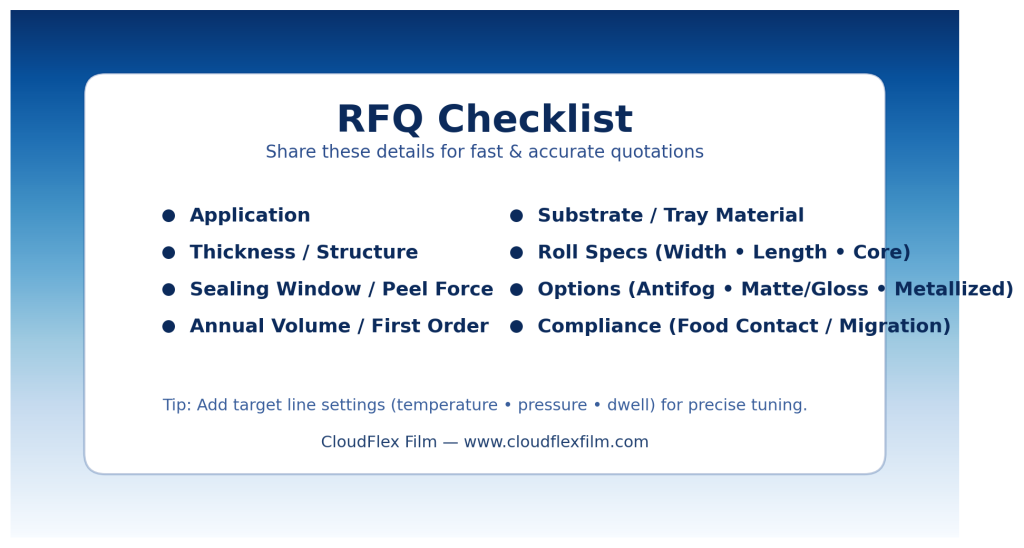

RFQ Checklist & How CloudFlex Can Help

When requesting a quotation, share:

-

Application (lidding/pouch/flow-wrap)

-

Substrate or tray/bowl material

-

Thickness and roll specs (width/ID/length)

-

Seal window and target peel force (if any)

-

Options (antifog, matte/gloss, metallized)

-

Annual volume and first order size

-

Compliance needs (food contact/migration)

Alt: Card listing RFQ data points: application, substrate, thickness, roll, seal, options, volumes.

CloudFilm supplies CPP, CPE, cast PE, metallized cast, and recyclable mono-material PE/PP films. Typical MOQ ~1 ton, lead time ~20 days with possible faster slots.

Learn more at www.cloudflexfilm.com.