Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials?

In the global packaging industry, where $917 billion was spent in 2024 alone, one material has emerged as the gold standard for protecting sensitive products: EVOH Barrier. Consider this: 40% of food waste globally is caused by inadequate packaging, while pharmaceutical losses due to moisture penetration exceed $3 billion annually.

These staggering numbers highlight a critical need for advanced barrier solutions—and EVOH Barrier delivers.

What Exactly is EVOH Barrier?

EVOH (Ethylene Vinyl Alcohol Copolymer) is a semi-crystalline polymer synthesized through the copolymerization of ethylene and vinyl alcohol monomers. Its molecular architecture combines the flexibility of polyethylene with the polar, gas-resistant properties of polyvinyl alcohol, resulting in a material that blocks oxygen, carbon dioxide, and hydrocarbons with unprecedented efficiency.

Why This Guide is Essential

Whether you’re a packaging engineer designing a new beverage container, a procurement manager sourcing materials for medical devices, or a sustainability director seeking eco-friendly alternatives, this guide will equip you with actionable insights.

We’ll explore EVOH’s science, real-world applications, selection criteria, and future trends—all tailored to help you leverage this technology for product success.

I. Understanding EVOH Barrier: Properties and Core Advantages

1.1 The Science Behind EVOH’s Superiority

EVOH’s barrier performance stems from its unique molecular structure. The vinyl alcohol segments form strong hydrogen bonds, creating dense crystalline regions that act as impermeable barriers to gas molecules. Meanwhile, ethylene segments provide chain flexibility, making EVOH processable via extrusion, blow molding, and lamination.

This balance of rigidity and flexibility is why EVOH outperforms alternatives like PVDC (polyvinylidene chloride) and PA (polyamide).

1.2 Key Performance Metrics Explained

- Oxygen Transmission Rate (OTR): Measured in cc/㎡·day, this is EVOH’s most critical metric. A typical EVOH film with 32% ethylene content achieves an OTR of 0.3 cc/㎡·day at 23°C and 65% RH—100 times lower than PET (30 cc/㎡·day) and 1,000 times lower than LDPE (300 cc/㎡·day).

- Moisture Resistance: While pure EVOH absorbs water (which slightly reduces OTR), combining it with moisture-resistant layers like PE or PP creates a composite with WVTR (Water Vapor Transmission Rate) as low as 0.5 g/㎡·day.

- Chemical Compatibility: EVOH resists most organic solvents, acids, and bases, making it ideal for packaging pharmaceuticals and industrial chemicals.

1.3 Comparison with Traditional Barrier Materials

| Material | Oxygen Transmission Rate (cc/㎡·day) | Moisture Resistance | Temperature Tolerance | Eco-Friendliness | Cost (USD/kg) |

|---|---|---|---|---|---|

| EVOH (32% ethylene) | 0.1–0.5 | Excellent (when laminated) | -40°C to 120°C | Recyclable | $8–12 |

| PVDC | 0.3–0.8 | Good | -20°C to 100°C | Non-biodegradable | $6–9 |

| PA (Nylon 6) | 1–5 | Poor | -40°C to 150°C | Recyclable | $5–7 |

II. How EVOH Barrier Achieves “Zero Permeation”: A Deep Dive

2.1 Molecular Mechanism of Gas Blocking

Gas permeation through polymers occurs in three stages: sorption (gas molecules dissolve into the polymer), diffusion (molecules move through the material), and desorption (molecules exit the other side). EVOH’s tightly packed crystalline structure slows diffusion to a near halt.

For example, oxygen molecules (0.346 nm diameter) struggle to pass through EVOH’s 0.2 nm-wide amorphous regions, resulting in the lowest diffusion coefficients among commercial polymers.

2.2 Processing Factors That Impact Performance

- Ethylene Content: Higher ethylene content (e.g., 44%) increases flexibility but slightly reduces barrier properties; lower content (e.g., 29%) boosts OTR performance but requires careful processing to avoid brittleness.

- Film Thickness: A 10μm EVOH layer provides 90% of the barrier efficiency of a 20μm layer, making thin-gauge EVOH ideal for cost-sensitive applications.

- Lamination Techniques: Co-extrusion (integrating EVOH with PE/PP in one step) creates stronger bonds than adhesive lamination, reducing delamination risks in high-humidity environments.

III. Industry Applications: Where EVOH Barrier Shines

3.1 Food & Beverage Packaging: Extending Freshness Beyond Limits

- Meat and Poultry: Vacuum-sealed EVOH/PE pouches extend shelf life from 5 days (conventional packaging) to 30+ days by preventing oxidative rancidity and microbial growth. A study by the American Meat Science Association found that beef steaks packaged in EVOH retained 85% of their original color after 21 days, compared to 40% in PA films.

- Carbonated Beverages: EVOH monolayer bottles reduce CO₂ loss by 90% compared to PET, keeping drinks fizzy for 12+ months. Coca-Cola’s “PlantBottle” uses EVOH to maintain carbonation while incorporating renewable materials.

- Ready-to-Eat Meals: Retort pouches with EVOH layers withstand 121°C sterilization, allowing shelf-stable packaging for soups and curries without preservatives.

3.2 Pharmaceutical and Medical Packaging: Ensuring Efficacy and Safety

- Vaccines and Biologics: EVOH blister packs and vial coatings protect temperature-sensitive drugs like mRNA vaccines. Moderna’s COVID-19 vaccine packaging uses EVOH to maintain stability at -20°C for 6 months.

- Controlled-Release Drugs: EVOH matrices regulate drug diffusion rates, enabling once-weekly formulations for chronic conditions like hypertension.

- Medical Devices: EVOH films in wound dressings block bacteria while allowing moisture vapor transmission, promoting faster healing.

3.3 Emerging Applications: Beyond Traditional Packaging

- Lithium-Ion Batteries: EVOH separators prevent electrolyte leakage and dendrite growth, improving battery life by 30% and reducing fire risks. Tesla’s 4680 battery cells use EVOH-based composite films.

- Solar Panels: EVOH encapsulants protect photovoltaic cells from moisture and UV radiation, increasing panel lifespan from 25 to 35 years.

- Aerospace Components: EVOH coatings on fuel tanks block hydrocarbon permeation, reducing emissions and improving fuel efficiency in commercial jets.

IV. Selection Guide: How to Choose the Right EVOH Barrier

4.1 Step 1: Define Your Barrier Requirements

Start by identifying the primary threat to your product:

- Oxygen-sensitive products (e.g., nuts, oils): Prioritize low OTR (≤0.5 cc/㎡·day).

- Moisture-sensitive products (e.g., electronics, powdered pharmaceuticals): Opt for EVOH/PE composites with WVTR ≤1 g/㎡·day.

- High-temperature applications (e.g., retort foods): Select grades with ethylene content ≤32% for better heat resistance.

4.2 Step 2: Evaluate Processing Compatibility

EVOH requires specialized processing due to its high melting point (160–190°C). Ensure your manufacturer has experience with:

- Co-extrusion: For multi-layer films (e.g., EVOH/PE/PA).

- Solvent casting: For ultra-thin films (5–10μm) used in electronics.

- Thermoforming: For rigid containers like trays and blisters.

4.3 Step 3: Balance Performance and Cost

EVOH is premium-priced ($8–12/kg) but offers cost savings via extended shelf life and reduced waste. For budget-sensitive applications, consider:

- EVOH blends: Adding 10–20% EVOH to PE reduces costs while improving barrier properties.

- Thin-gauge films: 5–10μm EVOH layers provide sufficient barrier for most food applications at lower material usage.

4.4 Top EVOH Grades for Common Applications

| EVOH Grade | Ethylene Content | OTR (cc/㎡·day) | Processing Temperature | Ideal Use Case |

|---|---|---|---|---|

| Soarnol™ E3808 | 32% | 0.3 | 180–200°C | Food packaging |

| Eval™ F101A | 44% | 0.5 | 170–190°C | Medical devices |

| Kuraray™ L171B | 29% | 0.2 | 190–210°C | High-barrier films |

V. FAQs: Your EVOH Barrier Questions Answered

Q1: Is EVOH recyclable?

A1: Yes. EVOH composites (e.g., EVOH/PE) are compatible with existing plastic recycling streams. Mechanical recycling separates layers via density differences, while chemical recycling depolymerizes EVOH into reusable monomers.

Q2: Can EVOH be used in contact with acidic foods like tomatoes?

A2: Absolutely. EVOH is resistant to pH levels 2–12, making it suitable for acidic foods (tomatoes, citrus) and alkaline products (soy sauce).

Q3: How does humidity affect EVOH performance?

A3: At high humidity (>80% RH), EVOH absorbs water, increasing OTR by ~30%. This is mitigated by laminating with PE/PP, which acts as a moisture barrier.

Q4: What’s the shelf life of EVOH films?

A4: Unopened EVOH rolls stored in a cool, dry environment (25°C, <60% RH) have a shelf life of 12–18 months. Once opened, use within 3 months to prevent moisture absorption.

VI. Future Trends: Innovations Shaping the EVOH Market

6.1 Sustainability: Bio-Based and Recyclable EVOH

- Bio-based monomers: Companies like Kuraray are developing EVOH using ethylene derived from sugarcane, reducing carbon emissions by 40% compared to petroleum-based EVOH.

- Degradable blends: EVOH mixed with polylactic acid (PLA) creates compostable films for single-use packaging, addressing plastic waste concerns.

6.2 Smart Barrier Technologies

- Active EVOH films: Embedded oxygen scavengers (e.g., iron particles) react with residual oxygen, reducing OTR to near-zero for ultra-sensitive products like organic baby food.

- Sensor-integrated packaging: EVOH films with RFID tags monitor OTR in real time, alerting suppliers to breaches during shipping.

6.3 Market Growth Projections

The global EVOH market is projected to reach $35.2 billion by 2028, growing at a CAGR of 7.2%. Key drivers include:

- Rising demand for convenience foods in Asia-Pacific.

- Expansion of the pharmaceutical cold chain in Africa and Latin America.

- Adoption of EVOH in electric vehicle batteries (expected to grow at 15% CAGR through 2030).

Conclusion

EVOH Barrier is more than a packaging material—it’s a critical enabler of product innovation, sustainability, and consumer trust. By understanding its science, applications, and selection criteria, you can unlock new possibilities for your products, from extending shelf life to ensuring compliance with strict regulatory standards.

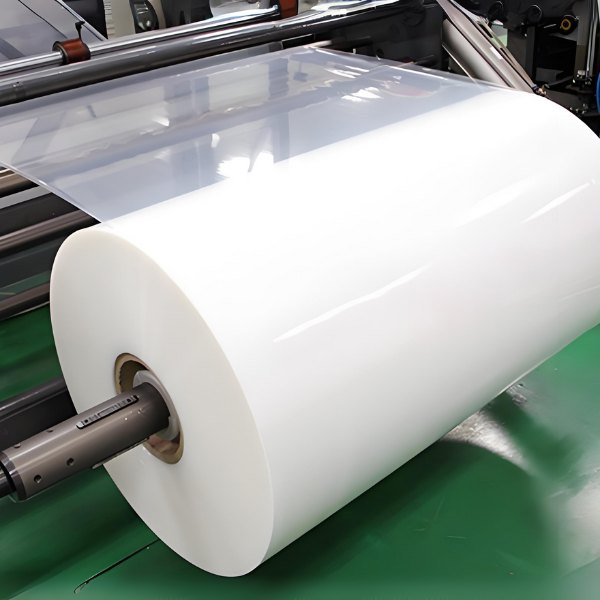

CloudFilm: Your Trusted EVOH Partner

CloudFilm is one of the best evoh film suppliers in China. We deliver custom EVOH barrier solutions tailored to your needs, from ultra-thin films (5μm) to heavy-gauge laminates. Our FDA-certified facilities ensure OTR as low as 0.1 cc/㎡·day, with fast turnaround and competitive pricing. Contact us today for a free sample and technical consultation.