Introduction

What is CPP Film?

Cast Polypropylene (CPP) film is a versatile and widely used material in the packaging industry. It is a type of polypropylene film that is cast or extruded to form a thin, flexible sheet. Known for its excellent clarity and gloss, CPP film plays a crucial role in enhancing the visual appeal of packaged products while providing a protective barrier against external elements.

CPP Film Manufacturing Process

The production of CPP film involves the extrusion of polypropylene resin through a flat die, followed by rapid cooling to solidify the film. This process allows for precise control over the film’s thickness and properties, resulting in a material that offers unique advantages such as high transparency, excellent mechanical strength, and superior barrier properties.

At CloudFilm, CPP film is produced on modern cast lines with tight gauge control, enabling stable thickness profiles and consistent sealing performance for converters and brand owners worldwide.

Purpose of This Article

This guide aims to provide comprehensive information about CPP film, helping you understand its properties, applications, and benefits. Whether you’re a packaging professional or simply exploring options for your products, this article will serve as a valuable resource for making informed decisions about CPP film.

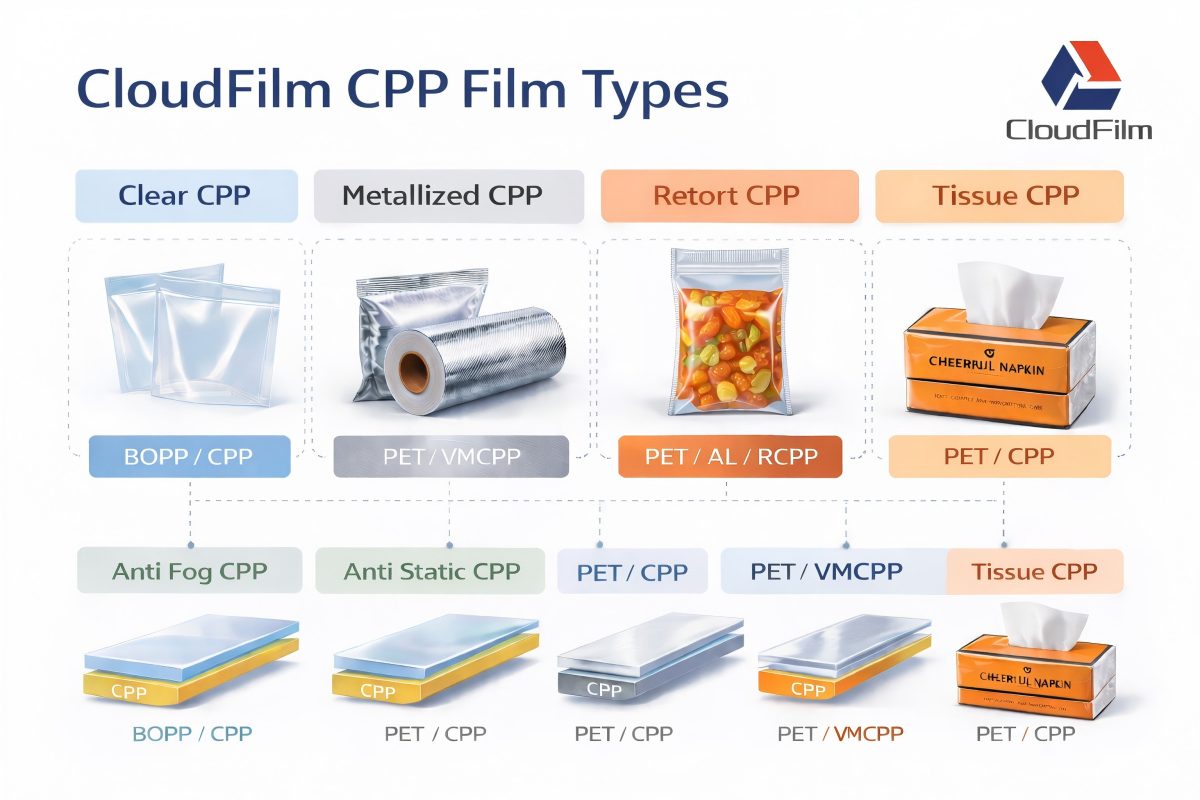

In addition, this article shows how CloudFilm’s CPP portfolio—including clear CPP, metallized CPP, retort CPP, anti-fog CPP, anti-static CPP and tissue CPP—can be matched to real packaging projects, from snacks and coffee to tissue, medical and technical products.

Characteristics and Advantages of CPP Film

Excellent Transparency and Gloss

One of the standout features of CPP film is its remarkable transparency and gloss. These properties make it an ideal choice for packaging products where visual appeal is essential. For instance, when used in food packaging, CPP film allows consumers to see the product clearly, enhancing its attractiveness on store shelves.

The film’s glossy finish further enhances the perceived quality of the product, making it more appealing to potential buyers.

For shelf-ready packs that demand maximum clarity—such as garments, stationery and premium snacks—CloudFilm’s Clear CPP Film and Clear Plastic Film structures help brands combine excellent transparency with the right stiffness and cost.

Superior Mechanical Properties

CPP film is known for its excellent mechanical properties, including high tensile strength, toughness, and tear resistance. These characteristics make it suitable for various packaging applications that require durability and protection.

For example, in the packaging of heavy or sharp-edged products, CPP film provides the necessary strength to prevent punctures and tears, ensuring that the contents remain secure during transportation and storage.

When extra toughness is required—for example for detergent pouches, hardware kits or bulk pet food—CloudFilm can combine CPP with BOPP, BOPET or BOPA to design laminates that pass drop tests and high-speed form-fill-seal (FFS) lines.

Outstanding Barrier Properties

In addition to its mechanical strength, CPP film offers superior barrier properties against moisture, oxygen, and oils. These barrier properties are critical in extending the shelf life of perishable products, such as food items, by preventing the ingress of moisture and oxygen that can lead to spoilage.

This makes CPP film an excellent choice for packaging snacks, baked goods, and other products that require a controlled environment to maintain freshness.

For moisture- and aroma-sensitive items such as coffee, milk powder and high-value snacks, CloudFilm often recommends laminates using Metallized CPP Film or PET CPP Film, which combine high barrier with attractive metallic or printed finishes.

Good Printability

CPP film is highly printable, making it an excellent substrate for high-quality graphics and branding. The film’s surface allows for the application of various printing techniques, including flexographic and rotogravure printing, enabling companies to create eye-catching designs that enhance brand recognition. With CPP film, packaging can be both functional and visually appealing, helping products stand out in a competitive market.

CloudFilm supplies corona-treated CPP rolls with controlled surface energy, ensuring stable ink adhesion for gravure, flexo and even digital over-printing, and can coordinate printing, lamination and slitting support for overseas converters.

Food-Grade Safety

Safety is paramount in food packaging, and CPP film meets stringent food-grade standards. It is manufactured using materials that are safe for direct contact with food, and it complies with relevant certifications and regulations. This ensures that CPP film can be used confidently in packaging applications where food safety is a top priority, such as for meats, dairy products, and ready-to-eat meals.

CloudFilm’s main CPP grades—including Retort CPP Film and CPP Tissue Film—are designed for food-contact use, with batch testing and traceability to support audits from brand owners and international retailers.

Applications of CPP Film

Food Packaging

CPP film is widely used in the food packaging industry due to its combination of strength, clarity, and barrier properties. It is commonly used for packaging a variety of food products, including meats, snacks, candies, and baked goods.

Its ability to preserve freshness while providing an attractive presentation makes it a preferred choice for food manufacturers looking to enhance the appeal and longevity of their products.

For typical food packs, CloudFilm often supplies structures such as BOPP/CPP, PET/CPP and PET/AL/RCPP, helping customers balance cost, barrier level and sealing window for snacks, coffee, sauces and retort meals.

Non-Food Packaging

Beyond food packaging, CPP film finds applications in non-food sectors such as pharmaceuticals and electronics. In the pharmaceutical industry, CPP film is used for blister packaging and other forms of medical packaging that require a high degree of protection and clarity.

In electronics, it serves as a protective layer for sensitive components, offering both physical protection and a barrier against environmental factors.

For electronics and pharma converters, CloudFilm can combine standard CPP with CPP Anti Static Film or high-barrier layers to protect ESD-sensitive devices, diagnostic kits and technical components.

Special Applications

CPP film is also utilized in specialized applications that require unique properties. For instance, in high-temperature sterilization packaging, CPP film can withstand the rigors of autoclaving processes, making it suitable for medical and laboratory applications. Additionally, it is used in vacuum packaging, where its barrier properties help preserve the freshness of vacuum-sealed products such as coffee and meats.

When your project involves retort pouches, high-temperature cooking bags or deep vacuum packs, CloudFilm’s Retort CPP Film and Metallized CPP Film can be tailored in thickness, COF and seal strength for reliable performance.

Classification of CPP Film

GCPP Film

General-purpose CPP (GCPP) film is known for its high transparency, good stiffness, low friction coefficient, and excellent heat-sealability. It is often used as a sealing layer in composite flexible packaging, particularly in combination with BOPP films. GCPP film is widely used in packaging for everyday products such as snacks, confectionery, and household items.

CloudFilm’s general-purpose CPP grades are widely used in BOPP/CPP pillow bags and flat pouches, and can be upgraded to CPP Tissue Film for tissue and toilet paper packs that demand extra softness and tear resistance.

MCPP Film

Metallized CPP (MCPP) film is manufactured using a special grade of polypropylene designed for metallization. It provides excellent adhesion to metal coatings, making it ideal for vacuum metallization processes. MCPP film is commonly used in packaging products that require an additional barrier layer, such as tea, biscuits, and crispy snacks.

The metallization process enhances the film’s barrier properties, making it suitable for products that need protection from light and oxygen.

For high-barrier snack and tea packs, CloudFilm’s Metallized CPP Film can be used alone or together with BOPP, BOPET or CPE to build custom VMCPP structures for chips, nuts, instant drinks and more.

RCPP Film

Retortable CPP (RCPP) film is available in two types: semi-retort and high-temperature retort. The semi-retort version can withstand sterilization at temperatures up to 120°C, while the high-temperature retort version can endure up to 135°C.

RCPP film is used in retort packaging, where it provides a durable, heat-resistant barrier that protects food products during the sterilization process. It is commonly used for packaging ready-to-eat meals, soups, and other heat-processed foods.

CloudFilm’s Retort CPP Film is engineered specifically for PET/AL/RCPP, PET/NY/RCPP and similar structures, ensuring strong seals and dimensional stability during retort, cooling and distribution.

Other Functional CPP Films

Other specialized CPP films include easy-peel and easy-tear films. Easy-peel CPP films are designed for convenient opening, making them ideal for products that require easy access, such as yogurt lids and snack pouches. Easy-tear CPP films offer controlled tearability, allowing consumers to open packaging without the need for scissors or other tools.

CloudFilm also offers easy-tear and easy-peel solutions across PP and PE structures—see Easy Tear Film and Easy Peel Film

—which can be combined with CPP-based laminates to improve consumer opening experience.

CloudFilm CPP Film Structures and Typical Laminates

To make CPP film selection more practical, it helps to think in terms of common structures and end uses. CloudFilm not only supplies CPP rolls, but also advises on how to combine CPP with BOPP, BOPET, CPE and aluminum foil in real projects.

Typical CPP-based solutions from CloudFilm include:

- Clear CPP as a sealant layer in BOPP/CPP and PET/CPP laminates for snacks, bakery and dry foods.

- Metallized CPP (VMCPP) for high-barrier tea, coffee, milk powder and crispy snack packaging, often in PET/VMCPP or BOPP/VMCPP structures.

- Retort CPP for PET/AL/RCPP and PET/NY/RCPP pouches, used in ready meals, sauces, pet food and shelf-stable soups.

- CPP Anti Fog Film for fresh produce tray lidding and pillow packs, keeping vegetables and fruit clearly visible in chilled cabinets.

- CPP Tissue Film for facial tissue and toilet paper overwraps, combining softness, gloss and tear resistance.

- CPP Anti Static Film or CPP-based ESD structures for sensitive electronics and components.

If you already have a draft specification (for example 12 μm PET / 7 μm AL / 60 μm RCPP or 20 μm BOPP / 60 μm CPP), you can send it to CloudFilm and our engineers will check feasibility, suggest thickness ranges and recommend suitable grades from our CPP, Cast Film and PP Film portfolio.

How to Choose the Right CPP Film for Your Packaging Project

Selecting the right CPP film is not only about thickness and price. It requires matching the film structure to your product, packing process and market requirements.

Key steps you can follow with CloudFilm are:

- Define the application and pack format – snack pillow bag, stand-up pouch, tissue overwrap, coffee valve bag, retort pouch, medical sachet, electronics ESD bag, etc.

- Clarify operating temperature and sterilization method – ambient, hot-fill, pasteurization or full retort; this drives whether standard CPP, RCPP or other high-temperature structures are required.

- Set barrier requirements – shelf life, oxygen and moisture sensitivity, light protection; decide whether clear CPP is enough or whether metallized CPP, PET/CPP or PET/AL/RCPP is needed.

- Check your packing lines – form-fill-seal speed, sealing jaw type, sealing temperature range and core size (3″ or 6″), to match CPP film COF, hot-tack and winding.

- Consider sustainability and recyclability – where possible, prioritize PP-based or mono-material structures (such as BOPP/CPP or all-PP laminates) that fit local recycling streams.

By sharing this information—together with target thickness, roll width and destination country—CloudFilm can quickly recommend CPP grades, provide technical data sheets and prepare trial rolls for your line tests.

Future Trends of CPP Film

Biodegradable CPP Films

As environmental concerns grow, the development of biodegradable CPP films is gaining momentum. These films are designed to break down more quickly in the environment, reducing their impact on landfills and ecosystems. The adoption of biodegradable CPP films is expected to increase as companies seek more sustainable packaging solutions.

Functional CPP Films

The demand for functional CPP films with special properties is also on the rise. Antibacterial CPP films, for example, are being developed to enhance the hygiene of packaged products. Anti-fog CPP films are another innovation, preventing condensation on the inside of packaging, which is particularly useful for fresh produce and refrigerated foods.

CloudFilm has already industrialized CPP Anti Fog Film and is actively expanding functional CPP portfolios such as anti-static, high-slip and printable grades to support new packaging concepts.

CPP Films in Smart Packaging

Smart packaging is an emerging trend where CPP films could play a significant role. Innovations such as temperature-sensitive films and films embedded with sensors could transform packaging into an interactive tool that provides real-time information about the product. CPP films, with their versatility and adaptability, are well-positioned to be part of this revolution in packaging technology.

CloudFilm can work with brand owners and converters on pilot projects that combine CPP with indicators, labels or digital printing technologies, helping you move gradually from conventional packs to smarter, more informative packaging.

Conclusion

Summarize the Advantages of CPP Film

CPP film offers a unique combination of transparency, strength, and barrier properties, making it an indispensable material in the packaging industry. Its versatility allows it to be used across a wide range of applications, from food packaging to specialized industrial uses.

Outlook for the Future

The future of CPP film looks promising, with ongoing developments in biodegradable and functional films. As the demand for more sustainable and innovative packaging solutions grows, CPP film will continue to evolve to meet the needs of the market.

Call to Action

To fully explore the potential of CPP film in your packaging solutions, consider how its properties can enhance your products. Whether you’re looking to improve shelf life, increase visual appeal, or explore new packaging technologies, CPP film offers a wide array of possibilities to help you achieve your goals.

If you are comparing options or already have a draft film structure, you can contact CloudFilm with your product, pack format and target thickness. Our team will recommend suitable CPP grades, provide samples and support you from specification to shipment.

CPP Film FAQs for Buyers and Packaging Engineers

Q1. What is the difference between CPP and BOPP film in packaging?

CPP film is a cast, non-oriented polypropylene film with a softer feel, wider sealing window and better hot-tack, making it ideal as an inner sealant layer. BOPP is biaxially oriented polypropylene with higher stiffness and dimensional stability, better suited as an outer printing or display layer. In many structures, BOPP is used outside and CPP is used inside as the sealing web.

Q2. When should I choose metallized CPP instead of clear CPP film?

You should consider metallized CPP when your product needs higher barrier against oxygen, moisture or light—such as coffee, tea, milk powder, nuts and premium snacks. The metallic layer significantly improves barrier performance and provides a shiny appearance. Clear CPP is sufficient for many dry foods, garments and stationery where barrier requirements are moderate and full transparency is preferred.

Q3. What thickness of CPP film is commonly used for food packaging?

For many food applications, CPP film typically falls in the 20–60 μm range as an inner sealant layer, depending on pack size, product weight and required stiffness. Thicker gauges may be used for large pillow bags, heavy products or retort pouches, while thinner gauges may be chosen for small sachets and laminates with stiff outer layers.

Q4. Can CPP film be used in retort packaging and high-temperature processes?

Standard CPP is not designed for full retort conditions, but specially formulated RCPP (retortable CPP) grades can withstand 120–135°C sterilization, making them suitable as the inner layer of retort pouches. When designing such structures, it is important to choose the correct RCPP grade and to verify performance through retort and abuse testing.

Q5. How should I choose between CPP, PE and CPE as a sealant layer?

CPP generally offers a wider sealing window and better optical properties than many PE films, making it ideal for transparent, high-appearance packs. CPE films provide excellent softness, low-temperature sealing and puncture resistance, which are useful for heavy or irregular products and frost-like garment bags. Many converters use CPP for pillow bags and pouches, and CPE for garment packaging or where extra softness is required.

Q6. What information should I provide when requesting a CPP film quote from CloudFilm?

To receive an accurate recommendation and quotation, it is helpful to share: product type, pack format (pillow bag, stand-up pouch, tissue overwrap, retort pouch, etc.), target structure (for example BOPP/CPP or PET/AL/RCPP), required thickness and width, printing requirements, expected annual volume and destination port.

Once CloudFilm has these details, our team can prepare technical recommendations, send CPP film samples for testing and offer a step-by-step roadmap from trial roll to mass production.