BOPET film is one of the most important polyester films used in modern flexible packaging. It combines high strength, clarity and barrier performance, so it protects your product and keeps your brand image sharp on the shelf.

CloudFilm (Qingdao Cloud Film Packaging Materials Co., Ltd.) supplies BOPET polyester film rolls for food packaging, coffee pouches, lidding films, labels and many other packaging formats. From clear printing film to metallized and high-barrier grades, our team helps you match the right PET structure to your product and packing machine.

You can also explore our BOPET film range and clear plastic film solutions to build complete laminates from one supplier.

Why Choose BOPET Film for Packaging?

- High temperature resistance

BOPET film has much better heat resistance than BOPP. It is ideal as an outer web in retort pouches, hot-fill packaging and ovenable packs where BOPP cannot survive. - Strong and stiff appearance

The film is stiff and has high tensile strength. Pouches stay flat, keep their shape and give a premium hand-feel. This helps your brand stand out on crowded shelves. - Excellent optical clarity

BOPET offers high gloss and transparency. Printed graphics look bright and sharp, and products remain visible in snacks, coffee, confectionery and bakery packaging. - Reliable barrier performance

When combined with metallized PET or ALOx PET high-barrier films, BOPET helps extend shelf life for coffee, nuts, dairy, pet food and other sensitive products. - Stable on high-speed lines

BOPET has good dimensional stability and controlled slip. It runs well on high-speed FFS machines, laminators and flexographic or gravure printing presses. - One-stop PET solutions from CloudFilm

CloudFilm also provides heat sealable PET film, gloss PET film and PET film rolls, so you can build complete PET-based structures with one supplier.

What Is a BOPET Film?

BOPET (Biaxially Oriented Polyethylene Terephthalate) film is a stretched polyester film. It is oriented in both machine direction and transverse direction. This orientation gives the film high tensile strength, good dimensional stability and excellent optical clarity.

In packaging, BOPET film is normally used as the outer printing layer or as a barrier layer inside the laminate. It is common in flexible packaging for food, coffee, tea, pet food, personal care and technical products.

Compared with non-oriented PET film, BOPET is stiffer, stronger and more stable at high temperatures. It does not shrink or deform easily during printing, lamination, pouch making or retort processes. Clear BOPET provides gloss and transparency, while metallized and ALOx PET films add high oxygen and moisture barrier.

BOPET Film Uses in Packaging

Food Packaging

In food packaging, BOPET film works as a clear, stiff outer layer in many laminates. It provides a stable printing surface and strong barrier support, especially when combined with metallized PET or ALOx PET film. Typical structures include PET/PE, PET/CPP and PET/AL/PE for coffee, nuts, powdered drinks, sauces and dried foods.

For coffee and aroma-sensitive products, metallized BOPET or aluminized PET film offers excellent oxygen and light barrier. It helps preserve flavour, colour and fragrance. For yogurt, cheese and dairy desserts, BOPET is also used as lidding film over PS, PP or PET cups, where it combines strong seals with clear product visibility.

CloudFilm can supply food-contact grade PET films and ready-to-print laminates for many of these food packaging applications.

Print & Paper Lamination

BOPET film is widely used in print lamination for book covers, magazines, premium cartons and advertising materials. Its clarity and gloss make colours look vibrant, while the stiff polyester base resists creases and scratching during handling.

For high-end packaging and graphic projects, gloss PET film and soft-touch PET films are popular choices. When laminated onto paper or paperboard, BOPET adds both protection and a premium finish. Metallized BOPET can also create metallic effects on cartons, labels and gift boxes, without using heavy foil.

CloudFilm offers PET lamination films in different finishes (gloss, matte, soft touch, metallized) to support both packaging and publishing markets.

Vacuum Metallized Packaging

Vacuum metallizing deposits a very thin aluminium layer onto BOPET film. This turns it into a high-barrier and highly reflective material. These aluminized PET films are widely used in snack, coffee, instant drink and dry food packaging where long shelf life and strong visual impact are required.

In many structures, metallized BOPET replaces traditional aluminium foil to reduce weight and improve flex-crack resistance. Typical laminates include PET-MET/PE, PET-MET/CPP and PET-MET/PE/EVOH for pouches, sachets and wraps.

CloudFilm can recommend metallized BOPET grades and laminate designs based on your barrier targets, filling method and packing speed.

Labels & Wrap-Around Applications

BOPET film is also used for durable labels, shrink sleeves and wrap-around labels on beverages, household products and industrial containers. Its stiffness, heat resistance and gloss help labels stay flat and legible in cold-chain, hot-fill or outdoor conditions.

In twist-wrap candy packaging, PET twist film gives strong twist memory and a crisp look as an eco-friendly alternative to PVC and cellophane.

For premium promotional items and security labels, PET holographic film adds visual impact and anti-counterfeiting features while keeping the mechanical strength of BOPET. By combining these speciality PET films, brand owners can upgrade both appearance and performance of their labels and wraps.

Other Technical Uses (Short Overview)

Beyond packaging, BOPET film is also used in industrial coatings, cable wrapping, electrical insulation and metallic yarn. Its dielectric strength, chemical resistance and dimensional stability make it a reliable substrate for technical applications.

If you are working on both packaging and industrial projects, the CloudFilm team can help you select PET grades that serve multiple roles in your product portfolio.

Typical BOPET Packaging Structures & Specifications

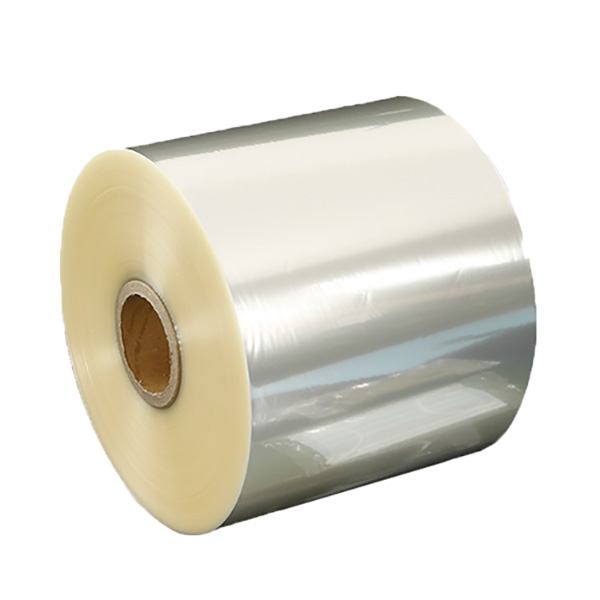

CloudFilm supplies BOPET polyester film as jumbo rolls and slit rolls for a wide range of packaging structures.

- Common laminate structures

- PET/PE for snacks, bakery and frozen food pillow bags

- PET/CPP for retort pouches and hot-fill sauces

- PET/AL/PE or PET-MET/PE for high-barrier coffee, nuts and milk powder

- PET/PE/EVOH/PE for premium dry foods and retort applications

- Typical thickness range

- 8–25 µm for printing and lamination BOPET

- 12–36 µm for metallized and high-barrier PET films

- Roll options

- Custom width, length and winding direction

- 3″ or 6″ cores

- Jumbo rolls for your own slitting or ready-to-run slit rolls

If you already use structures such as PET/AL/PE, PET/CPP or PET/PE for your food packaging film, we can match your current technical data sheets and provide sample rolls for line trials. For new projects, our team can recommend suitable packaging film rolls and clear plastic films based on your product, shelf-life target and filling process.

Key Benefits of BOPET Film for Packaging

- Performance at high temperature

BOPET keeps its shape and dimensions at elevated temperatures. It is reliable during drying, heat sealing, retort and hot-fill processes. - High barrier with the right structure

In clear form, BOPET provides good basic barrier to gases and aromas. When combined with metallization, ALOx or special coatings, it becomes a truly high-barrier layer for sensitive products. - Mechanical strength and puncture resistance

BOPET adds strength to the laminate, improves puncture resistance and reduces risk of pinholes or damage during transportation. - Premium look and feel

High gloss, transparency and stiffness give your packaging a clear “premium” look. This supports brand positioning in the mid-to-high market segment. - Support for sustainability goals

BOPET-based laminates can be light-weighted compared to foil-based structures. Where local recycling systems allow, mono-material PET solutions can also be developed. You can learn more about sustainable flexible packaging structures in CloudFilm’s flexible packaging solutions guide.

How to Choose the Right BOPET Film for Your Packaging Project

When you select BOPET film for packaging, it helps to follow a simple step-by-step process:

- Define your product and shelf-life target

Is it dry food, coffee, dairy, frozen food or pet food? How many months of shelf life do you need at which temperature range? - Decide the pack format

Pillow bag, stand-up pouch, quad-seal bag, lidding film, flow-wrap or vacuum pack – each format may need different stiffness and barrier levels. - Select the film role

Will BOPET act as the printed outer web, a barrier layer in the middle, or both? Clear, metallized and ALOx PET films each have different functions. - Match thickness and barrier

For most outer webs, 8–20 µm BOPET is enough. For high-barrier structures with metallization or coatings, slightly thicker gauges may be used. CloudFilm can share technical data sheets and barrier values on request. - Check line compatibility

Share your laminator, printing and packing line details with us. We can adjust slip, corona treatment and winding to match your equipment and reduce trial time.

If you send CloudFilm your current structure, packed product and destination market, our technical team can quickly recommend suitable BOPET grades, sample rolls and trial plans.

FAQ: BOPET Film for Packaging

Q1: Is BOPET film recyclable?

In many regions, clear BOPET film can be mechanically recycled when it is collected and sorted properly. However, multi-layer laminates such as PET/AL/PE are more difficult to recycle. CloudFilm can help you evaluate mono-material PET and recyclable structures where possible.

Q2: How is BOPET different from BOPP and BOPA in packaging?

BOPET offers higher heat resistance and stiffness than BOPP, so it is better as a printing and barrier layer in retort and hot-fill packs. Compared with BOPA, BOPET has slightly lower toughness but better optical clarity and higher temperature stability. For a more detailed comparison, see our guides on BOPP and BOPET films and the differences between BOPP, BOPET and BOPA.

Q3: Is BOPET film safe for direct food contact?

Yes. Food-contact grade BOPET films are widely used for direct-contact packaging. CloudFilm can supply suitable grades with available compliance statements for major markets when needed.

Q4: What is the minimum order quantity (MOQ)?

MOQs depend on thickness, width and whether the film is clear, metallized or coated. In many cases we can start with one jumbo roll per specification and provide small trial rolls for testing. Please share your specifications so we can confirm the exact MOQ.

Q5: Can CloudFilm provide printed or laminated BOPET film rolls?

CloudFilm mainly supplies technical BOPET film and other substrates, and we cooperate with converters to offer printed and laminated structures when projects require it. If you tell us your target structure and artwork, we can propose a practical supply route.

Work With CloudFilm

CloudFilm is a professional supplier of BOPET, BOPP, BOPA and other flexible packaging films from Qingdao, China. We focus on stable quality, fast response and long-term cooperation.

If you are searching for a reliable BOPET film partner, you are welcome to:

- Send us your current laminate structure and target application

- Request free sample rolls for trial on your lines

- Discuss new packaging projects that need high-barrier or speciality PET films

Contact the CloudFilm team to get a quick technical and commercial response for your BOPET film needs.