Unveiling the World of BOPP And BOPET Films

BOPP film and BOPET film are the two most common base films in modern flexible packaging. They look similar as clear plastic films, but their properties and best-fit applications are very different. The right choice directly affects shelf life, product safety, and how your brand looks on the shelf.

As a manufacturer and supplier of BOPP, BOPET and BOPA films in China, CloudFilm works every day with snack brands, coffee roasters, frozen food processors and converters around the world. This guide summarizes the key differences between BOPP and BOPET films and shows how to choose the right film for your next packaging project.

Why Choosing The Right Film Really Matters

Choosing packaging film is not just a matter of cost; this directly affects the sustainability and shelf life of the product. Packaging films have diverse degrees of chemical, cold, heat resistance, barrier properties, and mechanical strength, making the right choice important for manufacturers and consumers.

Wholesome Characteristics of BOPET and BOPP Films

BOPP Films: Exploring the Versatility and Cost-Effectiveness

Compared with the non-stretch film, biaxially oriented polypropylene (BOPP) film undergoes transverse and longitudinal stretching deformation in molding. Thus, the arrangement of its molecular chains or chain segments will change, significantly improving the film’s performance.

BOPP film has excellent mechanical strength, chemical, cold, and heat resistance, a good barrier, and a low price. It has become the most widely used packaging material, known as the “packaging queen.”

Key features of BOPP Films

- High Transparency and Glossiness

- Lightweight yet durable

- Good mechanical properties

- Eco-friendly

- Optimized for printing and processing

- Low cost

Enhancement in better functioning of BOPP Films

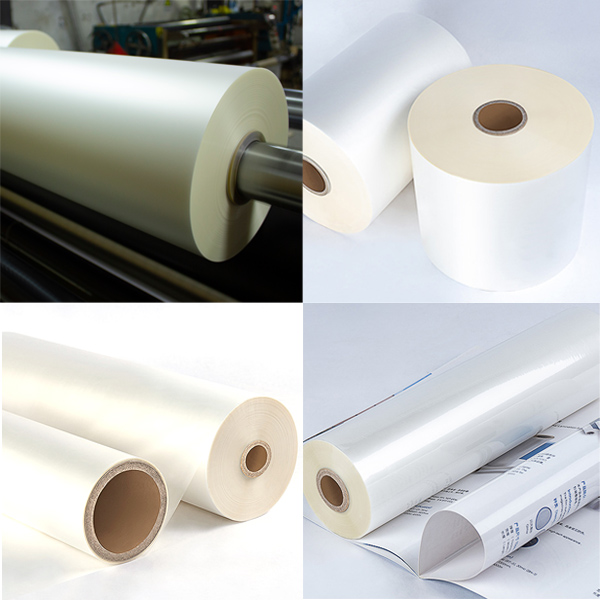

Although BOPP film has many excellent properties, its chemical structure does not contain active groups. Meanwhile, it becomes difficult to wet and bind for many reasons, such as high crystallinity, low surface energy, chemical inertness, surface pollution, and a weak boundary layer.

The poor wettability greatly limits the application of the BOPP film in ink, adhesives, composite materials, heat sealing, and coating areas. Therefore, the secondary treatment of the BOPP film is necessary to improve its wettability and adhesion.

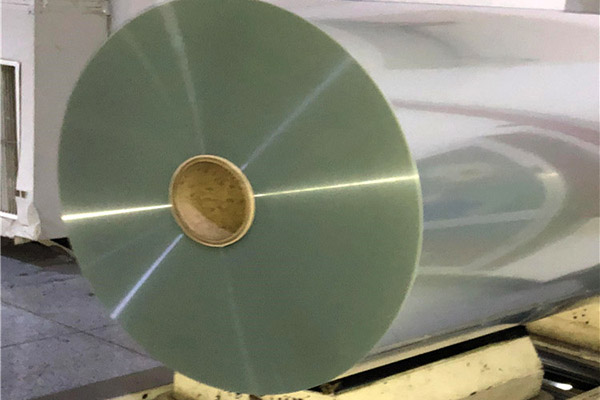

As a major manufacturer in China, CLOUD FILM offers an extensive range of BOPP films, encompassing gloss, thermal lamination, adhesive-free lamination, metalized, anti-fog, anti-scratch, coated, cigarette, and heat sealable films. These diverse BOPP films provide customers with high-quality products and the best packaging solutions.

BOPET Films: A Deep Dive into Durability and Lucidity

Biaxially oriented polyethylene terephthalate (BOPET) thin films are among the most exciting products for packaging applications. Their increased utilization is due to their outstanding properties, such as oxygen and water vapor barrier, high tensile strength, and complete recyclability.

Key features of BOPET

- Excellent transparency

- Excellent Mechanical strength

- Thermal stability

- Chemical resistance

- Good barrier properties

Enhancement in better functioning of BOPET

Typical treatments carried out on BOPET films involve the utilization of atmospheric, low-pressure, and vacuum electric discharge or the application of chemicals like alkali solution, which improves adhesion performance by increasing roughness, or polymeric lacquering, such as epoxy, vinyl acetate, or acrylic resins, that acts as a primer for further lamination processes.

BOPET films from CloudFilm are available in thicknesses ranging from 6 to 80 microns and various types, including Plain, Surface-Treated, Chemically Coated, Matte, Heat-Sealed, Metallizable, and extra-clear. These wide ranges of BOPET films ensure the highest standard to meet customer expectations. For high-barrier coffee packaging, BOPET is often used in PET/AL/PE structures.

Head-to-Head: Comparing BOPET and BOPP films

| Propert | BOPET | BOPP |

| Full name | Biaxially oriented polyethylene terephthalate | Biaxially oriented polypropylene |

| Resin | PET | PP |

| Tensile strength | High | High |

| Elongation at break | High | High |

| Modulus of elasticity | High | High |

| Yield strength | High | High |

| Tear strength | High | High |

| Impact strength | High | High |

| Puncture resistance | High | High |

| Stiffness | High | High |

| Hardness | High | High |

| Melting point | 260 oC | 170 oC |

| Glass transition temperature | 70 oC | −10oC |

| Density | 1.4 g/cm3 | 0.9 g/cm3 |

| Water absorption | Low | Low |

| Oxygen barrier | Good | Poor |

| Moisture barrier | Good | Poor |

| Chemical resistance | Good | Good |

| Heat resistance | Excellent | Good |

| Cold resistance | Excellent | Good |

| Optical properties | Excellent | Excellent |

| Printability | Good | Excellent |

| Cost | High | Low |

| Applications | Food packaging, beverage packaging,

electronic packaging, industrial applications, medical applications |

d packaging, beverage packaging, tobacco

packaging, stationery, textile packaging, gift wrapping, etc. |

For a deeper three-film comparison, you can also check our guide on BOPP, BOPET and BOPA films in packaging.

The Ultimate Guide to Choosing Between BOPET and BOPP Films

Aspects to Consider

BOPET and BOPP films are widely used in the packaging industry; each has advantages and application scenarios. When choosing, consider the following aspects:

Heat resistance

BOPET film has better heat resistance than BOPP film. If the packaging material needs to withstand high-temperature treatment (such as baking, microwave heating, etc.), BOPET film is more suitable.

Transparency and glossiness

BOPP film generally has superior transparency and glossiness, which is suitable for packaging that needs to display the appearance of the goods, such as food, candy, gift packaging, etc.

Tear resistance

BOPET film has better tear resistance than BOPP film, making it suitable for packaging that requires higher strength and durability, such as electronic products and industrial parts.

Barrier necessities

Barrier properties reflect the level of protection needed against air and moisture. BOPET film has good barrier properties compared to BOPP film.

Cost

The cost of BOPP film is usually lower than that of BOPET film. If cost is the main consideration, BOPP film may be preferred.

Environmental factors

The environmental performance of both materials is also a factor to consider when choosing. Generally speaking, BOPP film has better recyclability and is suitable for applications with higher ecological sustainability.

Expert recommendations

If you need to package frozen food that needs to be heated in a microwave, considering the need for heat resistance, BOPET film should be chosen. If you need to package candy, mainly considering displaying the appearance of the product and reducing costs, BOPP film can be chosen. In summary, when selecting between BOPP film and BOPET film, it is necessary to consider specific packaging requirements and product characteristics comprehensively.

Finally, from a packaging expert’s perspective, quality and sustainable environmental goals are critical for a customer considering the development of flexible packaging films from manufacture to disposal.

Quick Film Selection Guide For Common Applications

- Snacks, biscuits and candy – Start with BOPP-based laminates such as BOPP/CPP or BOPP/PE. You get strong moisture barrier, attractive gloss and competitive cost, ideal for mass-market snacks and sweets.

- Roasted coffee beans and ground coffee – Choose PET-based high-barrier structures such as PET/AL/PE or PET/EVOH-PE, usually with a degassing valve. This keeps aroma and flavor stable during shipping and storage.

- Frozen and microwaveable foods – PET/PE or PET/CPP structures give better temperature resistance and dimensional stability, helping packs survive freezing, thawing and reheating.

- Pharmaceutical and medical products – Use PET or nylon-based laminates with EVOH or aluminum foil layers when you need very high barrier, documentation and seal security.

- Recyclable mono-material packs – Where recycling systems allow, BOPP//BOPP or BOPE//BOPE structures can support mono-PP or mono-PE claims while still delivering good barrier and machinability.

Why Work With CloudFilm For BOPP And BOPET Films

CloudFilm focuses on flexible packaging films only. With BOPP, BOPET, BOPA, PE, CPP and high-barrier films under one roof, our team can recommend a full film structure instead of a single product.

For BOPP and BOPET films, we support:

- Thickness range from ultra-thin gauges for high-yield packaging to heavier films for industrial uses

- Plain, treated, coated, matte, metallized and heat-sealable grades

- Slitting to your exact width, core size and roll length for export cartons and pallets

- Technical support on COF, seal strength and laminate design

- Free samples and trial rolls for line testing before large orders

Tell us what you want to pack and how you pack it. CloudFilm will help you choose between BOPP, BOPET and other films, and send a clear quotation and solution.

FAQ: Choosing Between BOPP And BOPET

Q1. Is BOPET the same as “Mylar” film?

In many packaging discussions, “Mylar” is used as a common name for polyester film. Technically, BOPET is the generic material (biaxially oriented PET), while Mylar is a well-known brand name for some PET films. In practice, most flexible packaging “Mylar” structures are based on BOPET film laminates.

Q2. For snacks and confectionery, should I choose BOPP or BOPET?

For standard dry snacks, biscuits and candy, BOPP structures such as BOPP/CPP or BOPP/PE usually offer enough moisture barrier at a lower cost. If you need very long shelf life or strong aroma barrier, a PET-based laminate may be considered, but in many snack projects BOPP is the starting point.

Q3. For coffee packaging, why do many roasters use BOPET?

Roasted coffee is very sensitive to oxygen and aroma loss. High-barrier PET structures such as PET/AL/PE or PET/EVOH-PE, combined with a degassing valve, are widely chosen because they balance barrier, stiffness and branding space, especially for premium beans and export markets.

Q4. What information does CloudFilm need to recommend a film?

If you share your product type, target shelf life, filling and sealing method, machine type and current problems (for example, fogging, poor seals or curl), CloudFilm engineers can quickly recommend suitable BOPP or BOPET grades and laminate structures, then provide samples and a detailed quotation.

Conclusion: Making an informed decision

After evaluating the differences in characteristics between BOPET and BOPP films, your packaging requirements, and cost-effectiveness, you must decide which film to use. Each film offers specific properties and serves different purposes, making the selection highly dependent on the product’s specific needs and the manufacturer’s goals.

Selecting the appropriate film can improve your product’s shelf life and sustainability, eventually contributing to greater customer contentment and an eco-friendly environment.