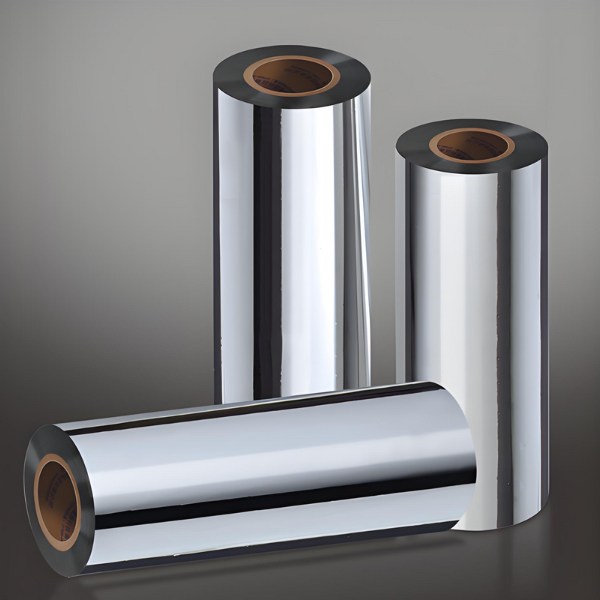

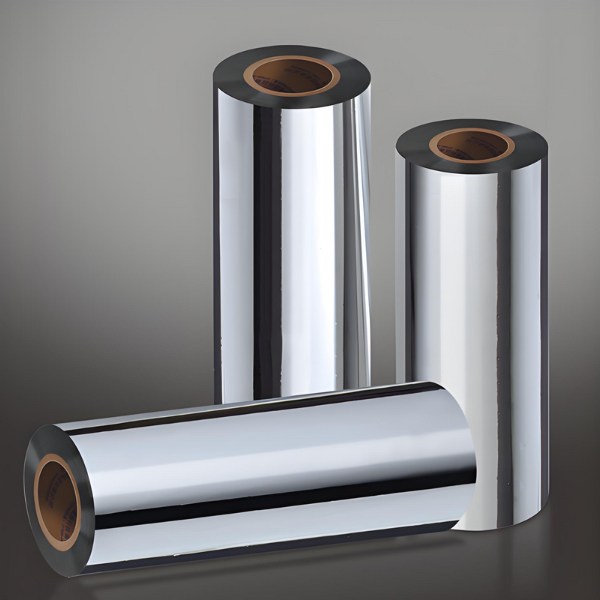

Cast Film

- CPP and CPE cast films for food, tissue, label and industrial packs

- Superb flatness reduces wrinkles and improves printing and lamination register

- Custom COF, slip and anti-block packages matched to your FFS and bag-making lines

- Corona-treated or primer-ready surfaces for gravure, flexo and digital printing

- Mono-material CPP/CPE structures that support recyclable pouch and bag designs

Cast Film Description

Cast Film Features & Structures

CloudFilm cast film is a flat-die, chill-roll extruded film based mainly on CPP and CPE resins. The process creates a smooth, uniform web with stable thickness and excellent clarity, making it ideal for printing, lamination and form-fill-seal (FFS) packaging lines.

We supply cast film in both single-layer and co-extruded structures using CPP film and CPE film. These films can act as sealing layers, printable outer webs or intermediate layers in laminates such as PET/CPP, BOPE/CPE or CPA/CPE, depending on your application and machine setup.

Slip and anti-block packages are fine-tuned to your target coefficient of friction (COF), so film reels run reliably on high-speed printing, lamination and bag-making equipment. Corona-treated and primer-ready surfaces are available for gravure, flexo and selected digital printing systems, helping you achieve strong ink adhesion and lamination bond strength.

Cast Film For Sustainable Packaging & Reliable Supply

Many brands are shifting toward mono-material PP and PE structures to support recyclable flexible packaging. Cast CPP and CPE films fit naturally into these designs, especially when paired with BOPE, MDOPE or other compatible webs in CloudFilm solutions such as our recyclable pouches and other mono-material bag structures.

CloudFilm supports your projects from sample roll to mass production with application engineering and quality control. Our team monitors thickness profile, COF, seal strength and appearance to help you keep stable line performance and reduce waste. Typical cast CPP/CPE thicknesses for packaging and lamination are in the 20–150 μm range, with widths, cores and treatment levels configured to your equipment and packing format.

For packs needing higher puncture resistance, deep-draw forming or extra barrier, cast CPP/CPE films can also be combined with Cast Nylon Film

or other high-barrier webs from the CloudFilm portfolio to build more advanced laminates for food, industrial and healthcare applications.

Get Free Sample of Cast Film

Ready to upgrade your packaging with clearer optics and smoother converting? Tell us your target gauge, COF, sealing window, and finish, and our engineers will recommend a matched CPP/CPE cast-film solution.

Request samples, data sheets, or a tailored quotation—optimized for your line speed and adhesion system.

Submit the form and we’ll reply with application guidance and next-step recommendations to accelerate trials and reduce total cost in use.

Cast Film Applications

Food & Snack Packaging – Cast CPP and CPE films are used as sealing or printing webs in biscuit, confectionery, frozen food and dry-food packs, often laminated with BOPP or PET. They offer clear product visibility and reliable seals for pillow bags, overwraps and lidding films.

Tissue & Hygiene Overwraps – Soft, clear cast films provide smooth wrapping for tissue packs, wipes and hygiene products, with controlled COF for high-speed overwrapping and good stiffness for shelf display.

Labels & Graphics – High-gloss cast film delivers a flat, smooth surface for labels, in-mould labels and graphic laminates where sharp print and low haze are critical.

Protective Films & Industrial Wraps – When used as a protective or lamination layer, cast films help shield hardware, electronics and components from dust, abrasion and moisture. For softer, cushioning behavior you can also explore our CPE film.

Healthcare & Personal Care Packaging – Clean, consistent film surfaces support hygiene requirements for medical devices, pharmaceutical pouches and cosmetic sachets, especially when combined with high-barrier layers or cast nylon film in laminates.

FAQ

Cast film is produced by extruding molten polymer through a flat T-die onto a chilled roll, where it quickly cools into a thin, uniform sheet. CloudFilm mainly uses CPP and CPE resins for cast films, giving high clarity, smooth surfaces and tight thickness tolerances that are ideal for printing, lamination and FFS packaging.

We primarily supply cast CPP and CPE films in single-layer and co-extruded structures. These can be used as sealing layers, printing webs or intermediate layers in laminates such as PET/CPP, BOPE/CPE or CPA/CPE. For higher puncture resistance or barrier, cast films can also be combined with Cast Nylon Film or high-barrier webs from our portfolio.

Compared with blown film, cast film typically offers higher clarity, smoother surfaces and more uniform thickness, which is excellent for high-quality printing and lamination. Blown film usually has higher mechanical strength and is preferred for heavy-duty sacks or agricultural films. For a deeper comparison, you can also refer to our article “Cast Film vs Blown Film: Which Is Right for Your Project?“

Yes. Food-contact compliant grades are available on request, and we can supply documentation such as COA/COC and migration test reports for export markets when needed. Cast CPP/CPE films can be corona-treated and paired with ink and adhesive systems suitable for gravure, flexo or digital printing.

As a general guideline, cast CPP/CPE films are usually supplied in thicknesses from around 20–150 μm for packaging and lamination uses. Width, core size, roll diameter and treatment level are configured according to your specific printing, lamination and bag-making equipment.

Yes. We support mono-PP and mono-PE concepts where cast CPP or CPE films are combined with BOPE, MDOPE or other compatible webs to build recyclable pouches and bags. You can also explore our recyclable pouches and our guide to recyclable flexible packaging for more ideas.

Our cast films run well on gravure and flexo presses, and selected grades can be used in digital printing workflows. They are commonly laminated with BOPP, BOPET, BOPE or CPA films to build high-performance structures for snacks, tissues, labels and industrial packs.

Yes. In addition to film rolls, CloudFilm can supply finished bags and pouches through our flexible pouches range, including stand-up pouches, flat pouches and quad-seal pouches. Cast films can be used as sealing layers or outer webs in these pouch structures, depending on your filling and shelf-life needs.

For standard cast CPP/CPE specifications, we typically offer flexible MOQs for trial rolls and more competitive pricing for larger, repeated production runs. Lead time generally depends on structure complexity, order quantity and printing/lamination requirements. Please share your forecast and target delivery date so we can propose a suitable supply plan.

To prepare an accurate quote, it is helpful if you can provide:

-

end-use application and packed product;

-

target structure (for example PET//CPP, BOPE//CPE or CPA//CPE);

-

thickness, width, roll length or weight requirements;

-

COF and sealing temperature range;

-

printing or lamination needs;

-

destination port and preferred Incoterms.

With this information, the CloudFilm team can quickly recommend a structure, send sample proposals and confirm pricing, MOQ and lead time.

Related News

CPP film density typically ranges from 0.90 to 0.92 g/cm³, which is a fundamental physical property that significantly influences the […]

Introduction: Why CPP Film Properties Matter For Packaging Buyers If you are a packaging engineer, buyer, converter […]

Introduction: Why CPP Film Matters For Modern Packaging Buyers Cast polypropylene (CPP) film has become one of the […]

In the world of plastic film manufacturing, two processes dominate the industry: cast film and blown film. For packaging engineers, product […]

Introduction: Why Mono-Material Flexible Packaging Matters In the last few years, “mono-material flexible packaging” has moved from a […]

Introduction What is CPP Film? Cast Polypropylene (CPP) film is a versatile and widely used material in […]

CPE films, also known as cast polyethylene films, have become a core material in modern flexible packaging. When […]

Retortable CPP film (also called retort CPP or RCPP) is one of the most important inner seal layers for […]