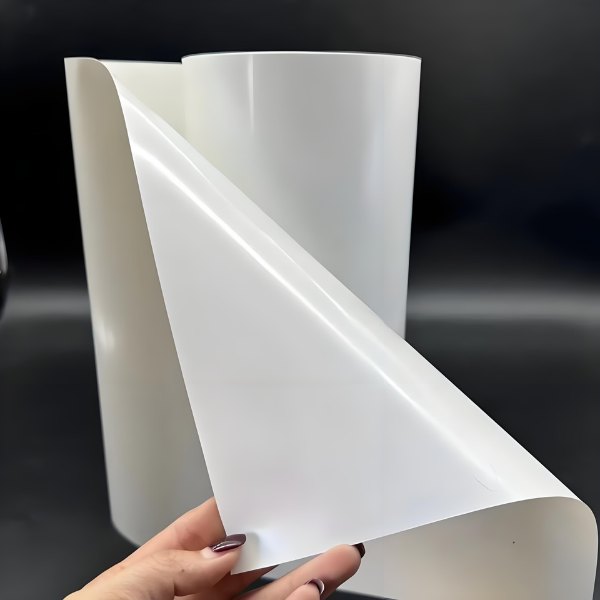

GAG Sheet

GAG sheet is a tri-layer PETG/APET/PETG rigid sheet that combines glass-like clarity with strong impact strength and stable thermoforming. It is widely used for blister packs, clamshells and printed display sheets in food, cosmetics, electronics and retail packaging.

- Tri-Layer PETG/APET/PETG Structure – Balanced rigidity, toughness and printability for demanding blister and clamshell packaging.

- Designed For Blister & Tray Forming – Suitable for vacuum forming, pressure forming and cold bending without stress whitening or cracking.

- Clear, Premium Shelf Appearance – High transparency and gloss help your products stand out on crowded retail shelves.

- Engineered & Supplied By CloudFilm – Consistent quality, export-ready documentation and tailored specifications for global converters and brand owners.

GAG Sheet Description

What is GAG Sheet?

GAG sheet is a PET-based, multi-layer rigid sheet produced by co-extruding PETG/APET/PETG. The APET core provides stiffness and dimensional stability, while the PETG outer layers add toughness, chemical resistance and excellent adhesion for printing, sealing and lamination.

Compared with full PETG sheet, GAG sheet delivers very similar clarity and impact strength but with a more cost-effective structure. It is widely used as a PVC-free alternative for blister packs, clamshells, display cards and thermoformed trays in food, cosmetics, electronics and consumer goods packaging.

Key Features & Advantages

Discover how CloudFilm GAG sheet supports both high-end packaging appearance and efficient mass production.

• Crystal-Clear Transparency

With over 90% light transmission, GAG sheet keeps printing, logos and products sharply visible behind the pack. This is ideal for cosmetics, toys, electronics and other retail goods where shelf appeal matters.

• High Impact Strength & Crack Resistance

The APET core and PETG skins work together to absorb shocks and prevent stress cracking during forming, transport and retail handling. This helps you reduce complaints and damage in the supply chain.

• Stable Thermoforming Window

GAG sheet offers a wide and forgiving forming window, enabling deep-draw shapes and fine details while maintaining uniform wall thickness. In many cases, it can be thermoformed without pre-drying, keeping your process simple and stable.

• Excellent Machinability & Post-Processing

Sheets can be die-cut, punched, routed, drilled and cold-bent with minimal whitening at the bend. The PETG surfaces accept offset, screen, UV and digital printing, as well as hot stamping, ensuring vivid graphics and reliable adhesion.

• Food-Safe & PVC-Free Sustainability

Based on recyclable PET polymers and free from chlorine, GAG sheet is a more sustainable alternative to PVC rigid sheet. Food-contact grades can be used for transparent lids, trays and blister packs when combined with appropriate lidding film or Easy Peel Film.

Why Choose CloudFilm?

CloudFilm is the PET and PETG packaging specialist behind a wide portfolio of BOPET films, PETG shrink films and rigid PET sheets. With more than 20 years of export experience, we understand the real needs of thermoformers, converters and brand owners across food, cosmetics, electronics and pharmaceutical sectors.

From first sampling through to container-load shipments, our team helps you define the right GAG sheet structure, validate it in trials and then lock in stable specifications. Backed by in-house QC and documentation support, CloudFilm offers consistent quality, clear communication and flexible service when you need matching lidding films, trays or other PET-based materials.

To match different blister, clamshell and tray projects, CloudFilm supplies GAG sheets with flexible specifications:

- Structure: Standard PETG/APET/PETG tri-layer; customized layer ratios can be discussed for special forming or printing requirements.

- Thickness: Typical range 0.20–1.00 mm for blister packs, clamshell trays and display cards; other gauges available on request.

- Width: Tailored to your thermoforming, die-cutting or sheet-cutting equipment to reduce trim waste.

- Format: Supplied as roll stock or cut sheets; surface can be protected with PE film if needed for high-gloss appearance.

- Surface & Finish: High-gloss transparent as standard; options for anti-scratch, anti-fog or matt finishes can be evaluated case by case.

- Color: Natural clear is standard; translucent tints, opaque white or black can be developed to support your branding and light-blocking needs.

- Compliance: Food-contact and RoHS/REACH-compliant grades are available for food, cosmetic, pharmaceutical and electronics packaging, with supporting TDS and DoC.

When you share your forming process, target tray depth and packaging line speed, our team will recommend a practical GAG sheet specification for your project.

Get Free Sample of GAG Sheet

Before you switch from PVC or full PETG sheet, a real production trial is usually the best way to validate GAG sheet on your lines. CloudFilm can prepare small-lot rolls or cut sheets so your team can test forming, printing and sealing performance.

To prepare the right sample and quotation, please share:

- End use (blister pack, clamshell, tray, display card, etc.)

- Target thickness range and sheet or roll format

- Required clarity and colour (clear, tinted, white, black, etc.)

- Whether food-contact or pharmaceutical compliance is needed

- Forming process and line speed (vacuum, pressure forming, etc.)

- Estimated monthly demand and first order quantity

GAG Sheet Applications

Blister & Clamshell Packaging

GAG sheet is ideal for transparent blister cards and clamshell packs used for cosmetics, personal care items, toys, stationery, batteries and small electronics. Its high clarity and impact resistance help protect products while keeping branding and contents visible at all times.

Food Trays, Lids & Cold-Chain Packs

Food-grade GAG sheets can be thermoformed into shallow trays, dome lids and cold-chain packs for salads, desserts and chilled snacks. When combined with our Food Packaging Trays

or Easy Peel Film, you can build a complete PET-based tray-and-lidding solution.

Printed Display Cards & Window Boxes

Thanks to its printable PETG surfaces, GAG sheet is suitable for printed display cards, folding cartons with windows, shelf displays and point-of-sale materials. It maintains stiffness and gloss even in thin gauges, helping your graphics stay flat and attractive.

Technical & Industrial Parts

Beyond packaging, GAG sheet can be processed into technical and industrial parts that require rigidity, impact strength and dimensional stability—such as protective covers, machine guards and electronic component housings. For projects that also need flexible barrier webs, you can pair GAG sheets with our PE PA PE Film or other high-barrier laminates.

FAQ

Store GAG sheets in a cool, dry and well-ventilated area, away from direct sunlight and heat sources. Keep them in their original packaging until use to minimize moisture absorption and avoid warpage before thermoforming or printing.

In many standard blister and clamshell applications, GAG sheets can be thermoformed without pre-drying, thanks to their PETG/APET/PETG structure. For very deep-draw shapes or critical cosmetic parts, we recommend a short drying step according to our TDS to ensure the most stable results.

Yes. GAG sheets are based on PET polymers and are generally compatible with PET recycling streams when collected separately from mixed plastics. Local recycling capabilities vary, so we suggest checking with your recycler or sharing your recycling targets with CloudFilm for guidance.

Typical thicknesses range from 0.20–1.00 mm, with customized widths to match your thermoforming or die-cutting lines. We can supply both roll stock and cut sheets; detailed specifications will be confirmed in our technical data sheet and quotation.

Food-contact and pharma-supporting grades are available for transparent lids, trays and blister packs, provided the final structure meets relevant FDA/EU regulations. CloudFilm can supply TDS, DoC and other documentation to support your internal approvals.

Compared with full PETG sheet, GAG offers similar clarity and impact strength with a more cost-efficient structure, while still maintaining good printability and formability. Versus mono-layer APET, GAG provides better toughness and a wider forming window, especially for deep-draw or complex shapes.

For standard grades, MOQ is usually set around one pallet or one production lot, and lead time is typically 2–4 weeks depending on thickness, colour and order volume. For new developments or special colours, we will confirm MOQ and timing separately when quoting.

Yes. In addition to GAG sheets, CloudFilm can provide APET Film, CPET Film, Easy Peel Film

and Food Packaging Trays. This allows you to source forming sheets, lidding films and finished trays from one partner.

Related Products

Related News

Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials? In the global packaging industry, […]

Introduction: Why Lidding Packaging is Crucial in Today’s Market Lidding packaging, also known as lid film or heat-seal […]

Introduction In the world of packaging, one term that frequently comes up—especially in food, pharmaceutical, and consumer […]

In modern flexible packaging, easy-peel films have become a quiet but powerful differentiator. For brand owners, converters, and packaging […]

Although PETG and PET differ by only one letter “G” in their names, in the field of modern material science, […]