PP EVOH PP

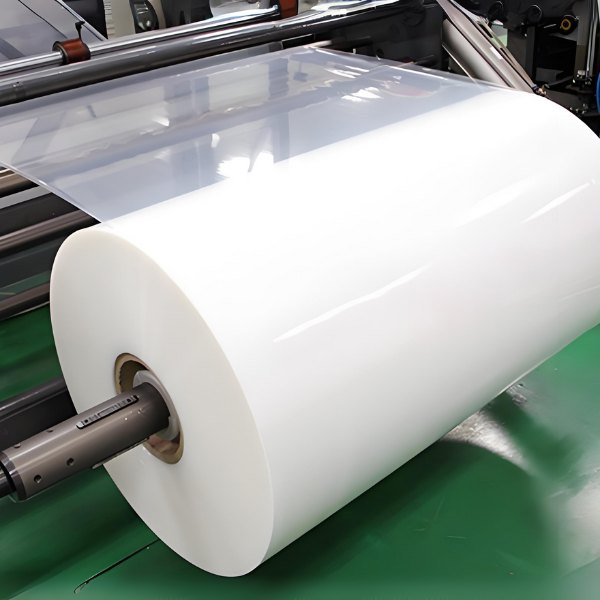

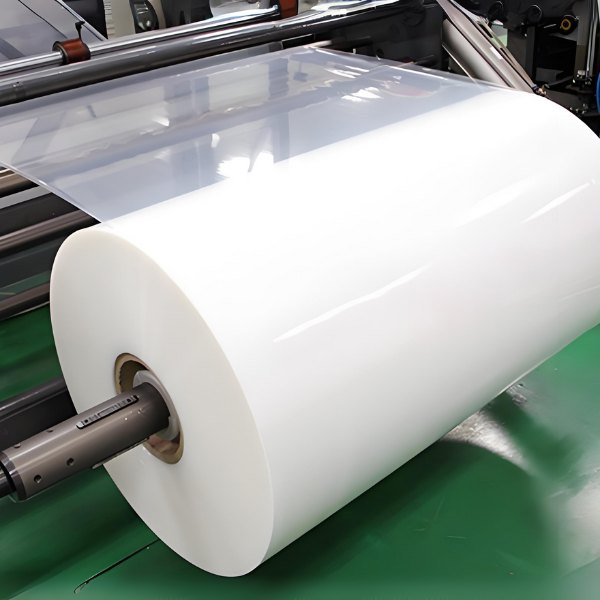

PP/EVOH/PP High Barrier Sheet: A multi-layer composite material that combines the strength of polypropylene with EVOH’s exceptional gas barrier properties, ideal for extending the shelf life of food and sensitive products.

-

✔️ Superior Barrier Protection: Exceptional gas (O₂/CO₂) and moisture barrier extends product shelf life significantly.

-

✔️ Excellent Strength & Durability: The PP outer layers offer robust mechanical strength, heat resistance, and chemical resistance.

-

✔️ Outstanding Processability: Ideal for thermoforming and other common plastic processing methods, ensuring packaging integrity.

-

✔️ Eco-friendly & Recyclable: Monomaterial-like structure (all-polyolefin) supports advanced recycling initiatives, enhancing sustainability.

PP EVOH PP Description

Introduction

PP/EVOH/PP is a high-performance, multi-layer composite sheet. Its core is a sandwich structure: two outer layers of robust Polypropylene (PP) encase a central layer of Ethylene-Vinyl Alcohol copolymer (EVOH).

This intelligent design combines the best properties of both materials to solve your most demanding packaging challenges.

Core Value & Performance

You need a material that guarantees product freshness and integrity. Our PP/EVOH/PP sheet delivers exactly that. The EVOH core provides an exceptional barrier against oxygen and aromas, drastically extending the shelf life of your sensitive products.

Meanwhile, the PP layers offer the mechanical strength, durability, and chemical resistance your production line requires, ensuring packages remain secure from factory to consumer.

Processing Advantages

You will appreciate how easily this material integrates into your existing operations. It is specifically engineered for excellent thermoformability, allowing you to create deep-draw, complex-shaped packages with consistent wall thickness and superior clarity.

This means higher production efficiency, fewer rejects, and a final package that looks as premium as it performs.

Application Focus

Your products deserve the best protection. This makes our PP/EVOH/PP sheet the ideal choice for packaging sensitive foods like cheeses, cooked meats, and ready-to-eat meals.

It is also perfectly suited for pharmaceuticals, medical devices, and high-end cosmetics, where maintaining a sterile, protective environment is critical.

Sustainability & Your Brand

You can also meet your sustainability goals. The primarily polyolefin-based structure of our sheets supports advanced recycling streams, contributing to a more circular economy.

By choosing this material, you are not just selecting a high-performance packaging solution; you are making a responsible choice for your brand and the environment.

About CloudFilm

As a trusted manufacturer and supplier, CloudFilm translates your packaging needs into reality. We provide more than just high-quality PP/EVOH/PP sheets; we deliver reliable technical support and customized solutions.

Partner with us to ensure your products are protected by material excellence.

Get Free Quote of PP EVOH PP

Is your packaging delivering the protection and performance you need? Our PP/EVOH/PP high-barrier sheet is engineered to solve your toughest challenges in freshness, strength, and sustainability.

Let’s discuss how it can be customized for your specific application.

PP EVOH PP Applications

1. Ready-to-Eat Meal Trays

Perfect for preserving the flavor and quality of prepared foods during storage and microwave heating.

2. Dairy Product Lids

Provides an excellent seal for yogurt cups and dessert containers, preventing oxidation and maintaining freshness.

3. Specialty Chemical Packaging

Safeguards sensitive industrial or agricultural chemicals from moisture degradation and contamination.

4. Advanced Medical Sterile Packaging

Used for high-end medical device and diagnostic kit packaging, ensuring a guaranteed sterile barrier.

FAQ

The key difference is their primary function. PP provides structural strength, chemical resistance, and moisture barrier. EVOH offers an exceptional oxygen and gas barrier but requires protection from moisture by layers like PP.

EVOH is the abbreviation for Ethylene-Vinyl Alcohol Copolymer. This unique molecular structure gives it its outstanding gas barrier properties.

Yes, EVOH itself is recyclable. In a PP/EVOH/PP structure, it can be processed in specialized polyolefin recycling streams, contributing to the material’s overall sustainability profile.

Related Products

Related News

Who This Guide Is For And How To Use It When buyers search for “packaging for frozen […]

Introduction: Why EVOH Barrier is the “King of Barrier” in Packaging Materials? In the global packaging industry, […]

Introduction: Why Compare Nylon and EVOH? Nylon (Polyamide, PA) and EVOH (Ethylene Vinyl Alcohol Copolymer) are two […]

Introduction: The Science Behind Packaging In our daily lives, we encounter a vast array of packages. From snack […]

CloudFilm supplies PVDC films, PVDC coated PET (KPET), BOPP (KOPP) and BOPA (KPA) structures to help packaging buyers turn […]

In modern flexible packaging, “product health” is more than just a marketing phrase. It is the sum of freshness, […]