Introduction: The Importance of Medical Flexible Packaging

Medical flexible packaging plays a crucial role in the healthcare industry, serving as the primary protective barrier for pharmaceuticals, medical devices, and diagnostic products. The global medical packaging market reached approximately $34.8 billion in 2023, with flexible packaging representing a significant and growing segment.

This comprehensive guide explores the fundamentals, market dynamics, applications, and future trends in medical flexible packaging, providing valuable insights for industry professionals, investors, and stakeholders seeking to understand this vital sector.

Basic Concepts of Medical Flexible Packaging

Medical flexible packaging refers to pliable packaging solutions that conform to the shape of the product while providing protection against external factors. These packages are typically constructed using plastic films, paper, aluminum foil, or combinations of these materials.

Unlike rigid packaging, flexible solutions offer lightweight, space-efficient alternatives that can reduce shipping costs and environmental impact.

The unique requirements for medical flexible packaging include exceptional physical and chemical properties, biocompatibility, and the ability to maintain product stability throughout the shelf life.

These packages must withstand sterilization processes, prevent contamination, and protect sensitive medical contents from moisture, oxygen, light, and other environmental factors that could compromise product integrity.

In-depth Market Analysis of Medical Flexible Packaging

The global medical flexible packaging market has demonstrated consistent growth, driven by expanding healthcare needs, technological advancements, and increasing regulatory requirements.

North America currently dominates the market, followed by Europe and the Asia-Pacific region, which shows the highest growth potential due to developing healthcare infrastructure and increasing pharmaceutical production.

Key market drivers include the growing pharmaceutical industry, aging populations requiring more medical products, stringent regulations ensuring product safety, and innovations in packaging materials and technologies.

However, the industry faces challenges such as environmental concerns regarding plastic waste, cost control pressures, and increasingly complex regulatory landscapes across different regions.

Table: Global Medical Flexible Packaging Market Overview

| Region | Market Share (2023) | Growth Rate (2024-2030) | Key Drivers |

|---|---|---|---|

| North America | 38% | 4.5% | Strict regulations, advanced healthcare system |

| Europe | 29% | 4.2% | Aging population, quality standards |

| Asia-Pacific | 22% | 7.8% | Growing pharmaceutical industry, healthcare investments |

| Rest of World | 11% | 5.3% | Improving healthcare access, rising standards |

Major Types and Applications of Medical Flexible Packaging

Medical flexible packaging can be categorized by material composition and application areas. By material, the main types include plastic-based packaging (using films like PVC, PET, PP), aluminum foil composites, and paper-plastic combinations. Each material offers specific barrier properties and suitability for different medical applications.

In terms of applications, medical flexible packaging serves various segments:

- Pharmaceutical packaging: Including blister packs, pouches for tablets and capsules, and sachets for powders

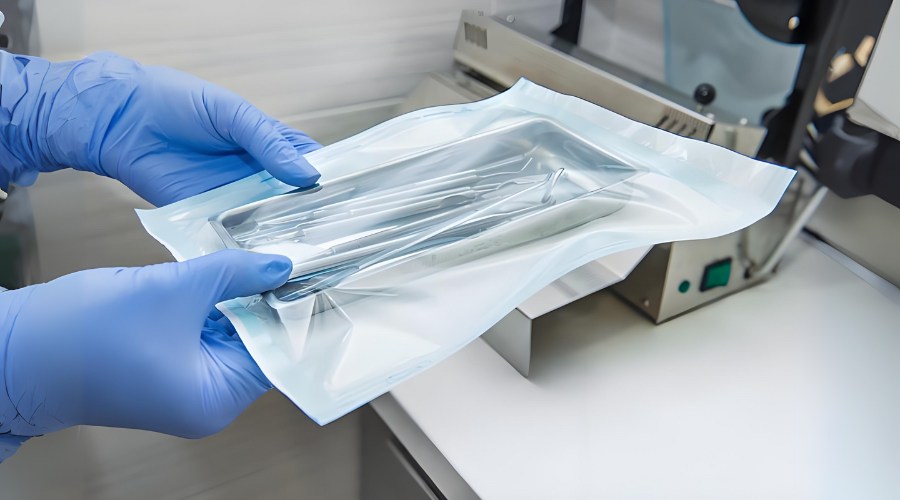

- Medical device packaging: For surgical instruments, implants, and disposable devices

- Diagnostic packaging: For test kits, reagents, and specimen collection containers

Innovative packaging forms have emerged to address specific needs, such as sterile packaging systems that maintain product sterility until use, child-resistant packaging for enhanced safety, and smart packaging with features like temperature indicators or authentication technologies.

Industry Leaders and Technology Trends

The medical flexible packaging industry is characterized by both large multinational corporations and specialized manufacturers. Key players include Amcor, Berry Global, Constantia Flexibles, and Sealed Air, among others. These companies invest heavily in research and development to maintain competitive advantages.

Current technology trends focus on sustainability, with increased use of recyclable materials and biodegradable alternatives. Smart packaging technologies incorporating QR codes, NFC, or RFID for tracking and authentication are gaining traction.

Additionally, high-barrier materials that extend product shelf life while reducing material usage represent a significant innovation direction.

Market Prospects and Investment Opportunities

The medical flexible packaging market is projected to grow at a CAGR of 5.8% from 2024 to 2030, reaching approximately $48.7 billion by the end of the forecast period. Key growth areas include emerging markets in Asia and Latin America, innovative materials with enhanced barrier properties, and smart packaging solutions that offer connectivity and data collection capabilities.

Investment opportunities exist in companies developing sustainable packaging solutions, those specializing in high-barrier materials for sensitive biologics, and firms offering integrated packaging services that combine design, manufacturing, and regulatory compliance support.

Conclusion and Recommended Resources

Medical flexible packaging represents a dynamic and essential component of the healthcare supply chain, balancing protection, sustainability, and cost-effectiveness. As the industry evolves, stakeholders must stay informed about material innovations, regulatory changes, and emerging market trends.

For further exploration, consider resources such as the Healthcare Packaging Association, industry reports from Smithers, and technical publications from packaging research institutes. Engaging with industry conferences and trade shows can also provide valuable networking and learning opportunities.

FAQs About Medical Flexible Packaging

Q1: What makes medical flexible packaging different from regular flexible packaging?

A1: Medical flexible packaging must meet stringent regulatory requirements for sterility, biocompatibility, and product protection. It undergoes rigorous testing and validation processes to ensure it can maintain product integrity and safety throughout its shelf life.

Q2: What are the most common materials used in medical flexible packaging?

A2: The most common materials include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polyvinyl chloride (PVC), aluminum foil, and various laminates combining these materials to achieve specific barrier properties.

Q3: How is sustainability being addressed in medical flexible packaging?

A3: The industry is focusing on recyclable mono-materials, reduced material usage through advanced designs, biodegradable alternatives where appropriate, and improved recycling processes. Some companies are also exploring reusable packaging systems for certain medical applications.

Q4: What regulatory standards govern medical flexible packaging?

A4: Key standards include ISO 11607 for packaging of terminally sterilized medical devices, USP standards for pharmaceutical packaging, and regional regulations such as FDA requirements in the US and EU MDR/MDR in Europe.

Q5: How is smart technology being incorporated into medical flexible packaging?

A5: Smart technologies include temperature indicators for cold chain products, authentication features to prevent counterfeiting, QR codes for product information and tracking, and RFID tags for inventory management throughout the supply chain.

CloudFilm offers innovative medical flexible packaging solutions that combine cutting-edge barrier technology with sustainable materials. Our expertise in custom packaging design ensures optimal product protection while meeting global regulatory standards. Partner with us for packaging solutions that enhance your product’s market appeal and performance.