Introduction: Why Lidding Packaging is Crucial in Today’s Market

Lidding packaging, also known as lid film or heat-seal lidding, is a specialized form of flexible packaging that provides secure, tamper-evident sealing for containers across various industries. From dairy products to medical devices, this technology ensures product safety, extends shelf life, and enhances consumer convenience.

With the growing global demand for efficient, sustainable, and visually appealing packaging, lidding packaging has become a cornerstone of the modern packaging industry.

According to market research data, the global lidding packaging market is projected to reach approximately $30 billion by 2027, with a compound annual growth rate (CAGR) of around 5.8%. This growth is primarily driven by the food and beverage industry, which accounts for over 60% of total demand. Increasing consumer preference for convenience foods and ready-to-eat products further fuels the demand for innovative lidding solutions.

Understanding Lidding Packaging: The Basics

1.1 What is Lidding Packaging? 🧩

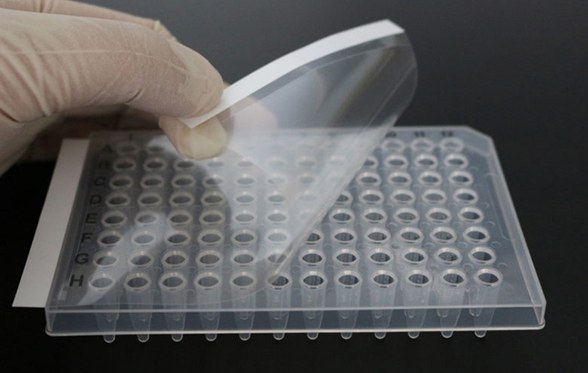

Lidding packaging is a heat-sealable film used to seal various containers, including trays, cups, and tubs. It bonds to the rim of the container through a heat-sealing process, creating an airtight seal that protects the contents from contamination, extends shelf life, and provides tamper evidence.

This type of packaging is especially suitable for products that require freshness preservation, leakage prevention, or product integrity.

Lidding films are typically composed of multiple layers, each serving a specific function:

- Outer layer: Provides a printable surface and mechanical strength

- Middle layer: Offers barrier properties (against oxygen, moisture, light)

- Sealing layer: Ensures reliable heat-sealing to the container

1.2 How Does Lidding Packaging Work? 🔧

Lidding packaging operates based on heat-sealing technology. During the packaging process, the film is placed over the filled container, and heat and pressure are applied to fuse the film to the container’s rim, forming a seal. This process can be performed on various packaging lines, from semi-manual operations to fully automated high-speed systems.

Key parameters of the heat-sealing process include:

- Temperature: Typically between 120°C and 200°C, depending on the material

- Pressure: Ensures proper contact between the film and container

- Time: Sufficient to form a strong seal without damaging the product

Modern lidding packaging systems integrate advanced control technologies to precisely monitor and adjust these parameters, ensuring consistent quality and performance.

1.3 Comparison of Lidding Packaging vs. Traditional Packaging Method 📊

| Feature | Lidding Packaging | Traditional Packaging (e.g., Lids, Caps) |

|---|---|---|

| Seal Integrity | Excellent, provides airtight seal | Good, but potential leak points |

| Material Usage | 30–50% less material | Typically requires more material |

| Opening Convenience | Designed for easy or peelable opening | Varies; sometimes difficult to open |

| Tamper Evidence | High, seal break is clearly visible | Moderate, depends on design |

| Sustainability | Generally lighter, less material | Usually heavier, more material usage |

| Cost Efficiency | Often more economical, especially in bulk | Varies, can be more expensive |

| Adaptability | High, customizable for various needs | Limited, constrained by standard designs |

Industries Using Lidding Packaging

2.1 Food and Beverage Industry 🥛

The food and beverage industry is the largest user of lidding packaging, accounting for over 60% of the market. From dairy products to ready meals, lidding packaging provides essential solutions to maintain freshness, safety, and convenience.

Key Applications Include:

- Dairy products: yogurt, pudding, cheese

- Ready meals: pre-cooked foods, microwaveable meal trays

- Beverages: coffee capsules, ready-to-drink teas and juices

- Fresh produce: pre-cut fruits, vegetable salads

- Meat and seafood: fresh and processed meats, seafood products

Industry Data:

- The global food packaging market is projected to reach $405 billion by 2027, with lidding packaging among the fastest-growing segments.

- The convenience food market is growing at approximately 7.5% annually, driving demand for innovative lidding solutions.

- Consumer surveys show that 85% of consumers consider packaging convenience an important factor in their purchasing decisions.

2.2 Medical and Pharmaceutical Industry 💊

In the medical and pharmaceutical sectors, lidding packaging provides critical protection to ensure the safety and sterility of medical devices and medications. These applications have stringent requirements and must comply with strict regulatory standards.

Key Applications Include:

- Medical devices: surgical tool kits, diagnostic equipment

- Pharmaceuticals: tablets, capsules, powders

- Diagnostic reagents: test strips, sample containers

- Disposable medical supplies: syringes, catheters

Industry Data:

- The global medical packaging market is expected to reach approximately $210 billion by 2026, with a CAGR of 6.2%.

- Sterile medical packaging accounts for over 40% of the medical packaging market, with lidding packaging as a key technology.

- Increasing regulatory requirements are driving demand for high-quality, compliant packaging solutions.

2.3 Personal Care and Cosmetics 🧴

The personal care and cosmetics industry uses lidding packaging to protect products, enhance brand image, and provide a consumer-friendly experience. From creams to shampoos, lidding packaging combines functionality with aesthetic appeal.

Key Applications Include:

- Skincare: creams, serums, facial masks

- Hair care: shampoos, conditioners, hair masks

- Color cosmetics: foundations, eyeshadows, lipsticks

- Fragrances: samples, travel sizes

Industry Data:

- The global cosmetics packaging market is projected to reach about $33 billion by 2025, with a CAGR of 4.8%.

- The premium cosmetics segment is driving demand for innovative packaging solutions, growing at approximately 6.5% annually.

- Consumer surveys indicate that 70% of consumers believe packaging design influences their purchasing decisions.

Material Types in Lidding Packaging and Their Applications

3.1 Peelable Lidding Films 🥄

Peelable lidding films are designed to be easily peeled away from the container, offering a consumer-friendly opening experience while maintaining seal integrity until use. This type is widely used in dairy, ready meals, and medical products.

Key Features:

- Controlled peel strength for easy opening without accidental opening

- Maintains seal integrity until consumer access

- Can be designed for full or partial peel

- Suitable for various container shapes and sizes

Application Examples:

- Yogurt and pudding containers

- Ready-meal trays

- Medical device packaging

- Cosmetic samples

3.2 Breathable Lidding Films 🌬️

Breathable lidding films allow gases (such as oxygen and carbon dioxide) to pass in a controlled manner while maintaining a barrier against liquids and microorganisms. This technology is especially useful for fresh produce and products that need to “breathe.”

Key Features:

- Precisely controlled gas transmission rates

- Maintains product freshness and shelf life

- Reduces condensation and spoilage

- Customizable to specific product respiration needs

Application Examples:

- Fresh-cut fruits and vegetables

- Bread and baked goods

- Certain types of cheese

- Active packaging applications

3.3 Anti-Fog Lidding Films 💧

Anti-fog lidding films are designed to prevent condensation from forming inside the package, maintaining product visibility and appeal. This technology is particularly important for refrigerated products and those requiring visual presentation.

Key Features:

- Special coatings or additives prevent water droplet formation

- Maintains product visibility and shelf appeal

- Reduces risk of microbial growth

- Suitable for refrigerated and temperature-variable environments

Application Examples:

- Fresh produce packaging

- Refrigerated ready meals

- Meat and seafood

- Pre-made salads

3.4 High-Barrier Lidding Films 🛡️

High-barrier lidding films provide exceptional protection against oxygen, moisture, light, and other environmental factors, significantly extending product shelf life. This technology is critical for sensitive products such as coffee, pharmaceuticals, and certain foods.

Key Features:

- Extremely low oxygen and moisture transmission rates

- Light protection (including UV)

- Excellent seal integrity

- Can be combined with other functional properties

Application Examples:

- Coffee and tea

- Pharmaceuticals and medical products

- Sensitive food ingredients

- Premium food products

Benefits of Lidding Packaging

4.1 Enhanced Product Protection and Shelf Life 🛡️

Lidding packaging offers superior product protection, significantly extending shelf life and reducing food waste. By providing effective barriers against oxygen, moisture, light, and microorganisms, lidding packaging ensures products remain in optimal condition from production to consumption.

Key Benefits:

- Extends shelf life by 30–100%, depending on product type

- Reduces oxidation and spoilage

- Prevents microbial contamination

- Maintains product flavor, texture, and nutritional value

Industry Data:

- Studies show that improved packaging technologies can reduce global food waste by approximately 20%.

- Consumer surveys indicate that 78% of consumers are willing to pay more for packaging that extends shelf life.

- Retailers report a reduction in return rates of about 15% for products using high-barrier lidding films.

4.2 Enhanced Consumer Experience 🛍️

Lidding packaging is designed with consumer convenience in mind, offering easy-to-open, resealable, and visually appealing solutions. These features enhance consumer satisfaction and can influence purchasing decisions.

Key Benefits:

- Easy opening without tools

- Resealable options to extend product usability after opening

- Clear product visibility

- Convenient to use and dispense

Industry Data:

- Consumer surveys show that 85% of consumers consider packaging convenience an important factor in their purchasing decisions.

- Easy-to-open packaging can increase consumer satisfaction scores by about 25%.

- Resealable packaging can reduce product waste and improve consumer loyalty.

4.3 Sustainability and Environmental Benefits 🌿

Modern lidding packaging solutions increasingly focus on sustainability, using less material, offering recyclable options, and reducing carbon footprints. These features align with growing consumer and regulatory demands for eco-friendly packaging.

Key Benefits:

- 30–50% reduction in material usage

- Recyclable and compostable options

- Lighter weight reduces transportation emissions

- Indirect environmental benefits from reduced food waste

Industry Data:

- The global sustainable packaging market is projected to reach approximately $500 billion by 2027, with a CAGR of 7.7%.

- Consumer surveys indicate that 74% of consumers are willing to pay more for sustainable packaging.

- Regulatory trends show increasing restrictions on single-use plastics globally.

4.4 Cost Efficiency and Operational Efficiency 💰

Lidding packaging offers significant cost efficiency and operational advantages, reducing material usage, increasing production line speeds, and lowering overall packaging costs. These benefits make lidding packaging an economical choice for manufacturers and brand owners.

Key Benefits:

- Reduced material costs

- Increased production line speed and efficiency

- Lower storage and transportation costs

- Reduced product waste and return rates

Industry Data:

- Manufacturers report that switching to lidding packaging can reduce packaging costs by 15–30%.

- Production line speeds can increase by 20–40%, depending on the application.

- Storage space requirements can be reduced by about 25% due to more compact packaging forms.

Future Trends and Innovations in Lidding Packaging

5.1 Sustainable Material Innovations ♻️

Sustainable material innovation is a major trend in the lidding packaging industry, including bio-based materials, recyclable structures, and compostable options. These innovations aim to reduce environmental impact while maintaining packaging performance and protection.

Key Development Directions:

- Bio-based polymers such as PLA and PHA

- Mono-material structures for easier recycling

- Compostable materials compliant with industrial and home composting standards

- Use of recycled content to reduce virgin material demand

Industry Data:

- The bio-based packaging market is projected to reach approximately $150 billion by 2026, with a CAGR of 15.1%.

- Consumer surveys show that 83% of consumers consider sustainable packaging an important part of brand responsibility.

- Regulatory trends indicate increasing global requirements for recyclable packaging.

5.2 Smart Packaging Technologies 🤖

Smart packaging technologies are transforming the functionality of lidding packaging, offering advanced features such as freshness monitoring, temperature control, anti-counterfeiting, and consumer interaction. These innovations enhance product safety, provide value-added services, and create brand differentiation opportunities.

Key Development Directions:

- Freshness indicators showing product status

- Time-temperature indicators monitoring cold chain integrity

- NFC and RFID technologies providing product information and anti-counterfeiting

- Interactive packaging enhancing consumer experience

Industry Data:

- The smart packaging market is projected to reach approximately $40 billion by 2025, with a CAGR of 8.1%.

- Retailers report that using smart packaging technologies can reduce product waste by about 10–15%.

- Consumer surveys indicate that 67% of consumers are willing to pay more for smart packaging that provides additional information.

5.2 Customization and Brand Differentiation 🎨

Customization and brand differentiation are important trends in lidding packaging, including advanced printing effects, unique opening mechanisms, and custom shapes. These innovations help brands stand out in a competitive market and create memorable consumer experiences.

Key Development Directions:

- Advanced printing technologies such as digital printing and embossing effects

- Custom opening mechanisms such as pull tabs and easy-tear features

- Unique shapes and design elements

- Brand integration and storytelling

Industry Data:

- Brands report that customized packaging can increase brand recognition by about 30%.

- Consumer surveys show that 72% of consumers believe packaging design influences their purchasing decisions.

- Market research indicates that unique packaging can increase product premium capability by about 15–20%.

How to Choose the Right Lidding Packaging Solution for Your Product

6.1 Assessing Product Needs 🎯

The first step in choosing the right lidding packaging solution is to thoroughly assess product needs, including product characteristics, shelf life requirements, target market, and brand positioning. These factors will guide material selection, functional features, and design decisions.

Key Considerations:

- Product composition and sensitivity (oxygen, moisture, light)

- Required shelf life and storage conditions

- Target consumers and their preferences

- Brand positioning and differentiation needs

- Regulatory requirements and industry standards

Assessment Steps:

- Conduct product characteristic analysis

- Identify key protection needs

- Evaluate target market expectations

- Consider brand positioning and differentiation opportunities

- Determine regulatory and standard requirements

6.2 Material and Functionality Testing 🧪

Material and functionality testing are critical steps to ensure the lidding packaging solution meets product needs. These tests evaluate material performance, seal integrity, shelf life extension effects, and consumer experience.

Key Test Types:

- Material performance testing (barrier properties, mechanical strength)

- Seal integrity testing

- Processing and production line compatibility testing

- Storage and shelf life testing

- Consumer experience testing

Testing Process:

- Preliminary material screening

- Laboratory performance testing

- Small-scale production testing

- Processing condition optimization

- Final validation and confirmation

6.3 Partnering with a Specialist Supplier 🤝

Partnering with a specialist supplier is key to ensuring the best lidding packaging solution. Experienced suppliers can provide technical expertise, material innovation, custom design, and comprehensive support to help you achieve your packaging goals.

Key Factors in Choosing a Supplier:

- Technical expertise and experience

- Material innovation and R&D capabilities

- Quality control and certifications

- Customer service and support

- Sustainability commitment

CloudFilm’s Advantages:

- 20+ years of industry experience

- Advanced material R&D capabilities

- Comprehensive quality management system

- Global technical support network

- Strong sustainability commitment

Frequently Asked Questions (FAQs)

Q1: What is lidding packaging?

A1: Lidding packaging is a heat-sealable film used to seal containers, providing tamper evidence while allowing easy consumer opening. It is widely used in the food, beverage, medical, and cosmetics industries.

Q2: What are the main types of lidding packaging?

A2: Main types include peelable lidding films, breathable lidding films, anti-fog lidding films, and high-barrier lidding films, each designed for specific product needs and applications.

Q3: How does lidding packaging extend product shelf life?

A3: By providing high barriers against oxygen, moisture, and light, lidding packaging significantly slows down product deterioration, extends shelf life, and reduces food waste.

Q4: What is sustainable lidding packaging?

A4: Sustainable lidding packaging uses recyclable, compostable, or bio-based materials, aiming to reduce environmental impact while maintaining packaging performance and protective functions.

Q5: How do I choose the right lidding for my product?

A6: Consider factors such as product composition, shelf life requirements, processing conditions, and sustainability goals. Our technical team can help you select the optimal solution.