Introduction: Why is PE the Workhorse of the Packaging World?

Every day, from the bread bag at breakfast to the industrial stretch wrap in a factory warehouse, to the bubble mailer from your latest online order, one material is ubiquitous, silently safeguarding our products—PE (Polyethylene) packaging film. As the world’s most produced and widely used plastic, PE has become deeply integrated into every corner of modern commerce.

But have you ever wondered why PE is the “evergreen tree” of the packaging industry? What magic does it possess that allows it to handle challenges ranging from food to industrial goods? If you are searching for the perfect packaging material for your product, or simply want to gain a deeper understanding of this seemingly ordinary yet crucial material, you’ve come to the right place.

This article will serve as your ultimate guide, taking you on a comprehensive journey through the world of packaging PE, from its fundamental properties and different family members to its vast application scenarios, and finally, teaching you how to expertly match the best PE packaging solution to your product.

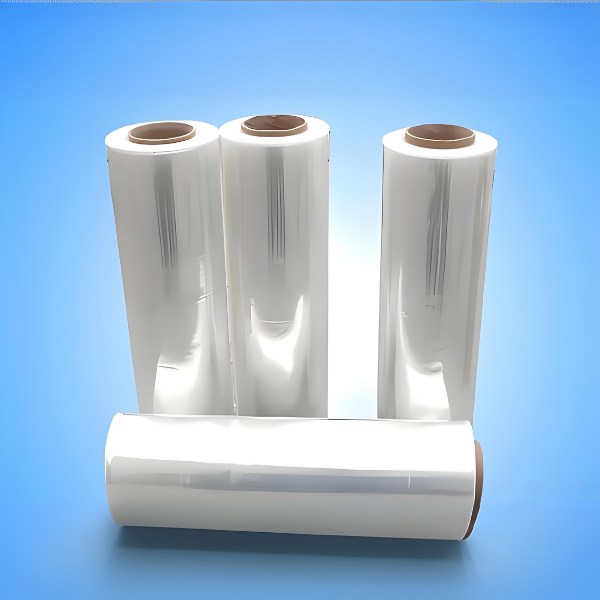

{ Blown Packaging PE Film }

Decoding PE: What is Polyethylene?

Before we dive in, let’s demystify PE. PE, short for Polyethylene, is a thermoplastic resin polymerized from ethylene monomers. Its structure is simple (repeating -CH2-CH2- units), but this simplicity endows it with a range of impressive properties that make it an ideal choice for packaging.

Choosing PE as a packaging material is primarily based on the following core advantages:

- Excellent Flexibility and Toughness: PE film is very soft and remains flexible even at low temperatures, effectively absorbing shocks and protecting contents from vibration and compression.

- Superior Moisture Resistance: PE has an extremely low water vapor transmission rate, meaning it acts as an excellent moisture barrier, which is critical for moisture-sensitive products like food and electronics.

- Good Chemical Stability: It resists corrosion from most acids, alkalis, and salts, ensuring the integrity and safety of the packaging without being easily attacked by its contents.

- Ease of Processing and Heat Sealing: PE can be made into film through various processes like blown film extrusion or cast film extrusion, and its heat-sealing performance is excellent, allowing for a strong, airtight seal at relatively low temperatures, which greatly enhances production efficiency.

- Cost-Effectiveness: Compared to high-performance barrier materials like Nylon or EVOH, the raw material and processing costs of PE are more competitive, providing businesses with a high-value packaging option.

- Recyclability: With the growing global emphasis on sustainability, the recyclability of PE has become a major highlight. Many PE products can be recycled and reused, reducing their environmental footprint.

The PE Family: Different Types of PE and Their Roles in Packaging

“PE” is not a single material; it’s a vast family. In the packaging world, the following core members are most frequently mentioned. Understanding their differences is key to material selection.

1. LDPE (Low-Density Polyethylene) – The Epitome of Softness and Clarity

- Properties: LDPE is the softest and most transparent member of the PE family. It possesses excellent ductility and is easy to heat seal.

- Packaging Applications: The bread bags, cling wrap, and many lightweight packaging bags that require a soft touch you see daily are mostly made from LDPE. In multilayer composite films, it is also often used as the inner heat-seal layer because it can easily seal to itself or other materials.

- Is it right for your product? If your product requires packaging that is soft, transparent, and easy to seal manually or by machine, LDPE is an excellent starting point.

2. LLDPE (Linear Low-Density Polyethylene) – The Champion of Strength and Toughness

- Properties: LLDPE can be seen as an “upgraded” version of LDPE. Its molecular chain structure is more regular, which gives it higher tensile strength, puncture resistance, and tear resistance than LDPE. Although its clarity is slightly less than LDPE, its overall mechanical properties are more outstanding.

- Packaging Applications: LLDPE is the core material for making stretch film, used to secure palletized goods. It is also widely used for making heavy-duty shipping sacks (for fertilizers, resin pellets), garbage bags, and composite films that require higher durability.

- Is it right for your product? If your product is heavy, has sharp edges, or needs to withstand significant tensile force during transit, LLDPE provides unparalleled protection.

3. HDPE (High-Density Polyethylene) – The Powerhouse of Rigidity and Barrier

- Properties: HDPE is distinctly different from LDPE and LLDPE; it is hard, rigid, and appears translucent or opaque. It has higher temperature resistance and better gas barrier properties (though its barrier to oxygen is still limited).

- Packaging Applications: The milk jugs, shampoo bottles, and laundry detergent bottles in your kitchen, as well as shopping bags at the supermarket, are mostly made from HDPE. It is also used to make industrial drums and containers.

- Is it right for your product? If you need packaging that has a certain shape, can stand on its own, and requires rigidity, HDPE is your first choice.

4. mLLDPE (Metallocene Linear Low-Density Polyethylene) – The Elite of Balanced Performance

- Properties: This is the “high-tech” member of the PE family. By using advanced catalyst technology, mLLDPE maintains or even surpasses the strength of LLDPE while also boasting clarity comparable to LDPE and excellent low-temperature heat-sealing performance.

- Packaging Applications: mLLDPE is often used in high-end food packaging, such as fresh produce packaging that requires high clarity and strength, and high-performance films that pursue “downgauging” to reduce costs and environmental impact.

- Is it right for your product? If you have extreme requirements for packaging performance and want to achieve lightweighting without sacrificing any metrics (strength, clarity, ease of sealing), mLLDPE is your ideal choice.

Application Areas of Packaging PE Film: It’s Everywhere

The versatility of PE makes its range of applications almost limitless. Here are some examples from key industries:

- Food and Beverage Industry: This is PE’s largest market. From cling wrap and bread bags (LDPE), to frozen food bags and composite films for fresh meat trays (LLDPE/LDPE inner layer), to milk and juice bottles (HDPE), PE ensures the freshness, safety, and hygiene of food.

- Industrial and Agricultural Sectors: In industry, LLDPE stretch film is the “lifeline” of logistics, while HDPE and LLDPE heavy-duty sacks carry chemical raw materials and mineral products. In agriculture, PE films for greenhouses and mulch provide powerful support for modern agriculture.

- Retail and Consumer Goods Industry: From soft packaging bags for apparel (LDPE), to bubble wrap (LDPE) that protects goods during shipping, to durable shopping bags (HDPE/LLDPE), PE plays a vital role in enhancing the consumer experience and protecting products.

- Medical Industry: HDPE is widely used to make pharmaceutical bottles and medical container caps due to its chemical stability and ease of molding. Some primary packaging for medical devices also uses specially treated PE film.

{ Packaging PE Has A Wide Range Of Applications }

How to Select the Right Packaging PE for Your Product?

Faced with so many choices, the decision-making process can seem daunting. Don’t worry, by following this three-step method, you can find your way with clarity.

Step 1: Define Your Product’s Needs

First, ask yourself a few key questions:

- What is my product? Is it food, a chemical, an electronic component, or a fragile glass item?

- What level of protection does it need? Does it need moisture protection, oxygen barrier, anti-static properties, or puncture resistance?

- What is my packaging format? Does it need to be made into pre-made bags, or is it a roll film for an automatic packaging machine? Does it need printing, or will it be natural?

- What is my budget? Cost is an important consideration, but it should be balanced with performance needs.

Step 2: Match the PE Type

Based on your answers, you can narrow down the type of PE. The quick reference table below can help:

| Priority Need | Recommended PE Type | Reason |

|---|---|---|

| Extreme softness, clarity, easy heat-sealing | LDPE | Best flexibility, good clarity, low heat-seal temperature |

| High strength, tear/puncture resistance | LLDPE | Far superior toughness and puncture resistance to LDPE, ideal for heavy-duty packaging |

| Rigidity, high-temperature resistance, structure | HDPE | High hardness, maintains shape, good heat resistance |

| Excellent overall performance, pursuing lightweighting. | mLLDPE | Combines high strength, high clarity, and excellent heat-sealability |

Step 3: Consider Processing and Printing

- Printing Needs: If you need to print exquisite patterns and text on your packaging, LDPE and mLLDPE generally have better surface treatment and printability.

- Production Line Speed: For high-speed automatic packaging lines, LLDPE and mLLDPE, due to their excellent toughness and openability, can run more stably, reducing downtime.

Why Choose CloudFilm as Your Packaging PE Expert?

{ Why Choose CloudFilm as Your Packaging PE Expert }

After understanding the theory of PE, choosing a reliable partner to turn this knowledge into a practical packaging solution is equally crucial. At CloudFilm, we are more than just a film manufacturer; we are your trusted packaging advisor and solution provider.

- More Than a Supplier, Your Packaging Advisor: We know that every product is unique. Our sales and technical teams take the time to listen to your needs, analyze your challenges, and provide you with tailored material recommendations based on our deep industry knowledge, rather than just pushing off-the-shelf products.

- Extensive Product Line: CloudFilm boasts a complete PE film production line, from LDPE, LLDPE, and HDPE to mLLDPE. Whether you need a single-layer film or a multilayer composite film that combines PE with materials like PET or Nylon to achieve higher barrier performance, we can meet your needs in a one-stop shop.

- Strong Customization Capabilities: Your imagination is the limit of our innovation. We can customize the thickness, width, color, and add special functional masterbatches (such as anti-static, anti-fog, slip/anti-block, etc.) according to your specific requirements, truly creating a film “born for your product.”