Introduction: Why Heat Shrink Film Packaging Matters For Modern Brands

Heat shrink film packaging has become a core secondary or outer packaging solution for food, beverage, household and industrial products. By wrapping a product or multi-pack with a thin plastic film that shrinks tightly when heated, brand owners achieve protection, tamper evidence and a clean, premium appearance in one step.

For purchasing managers, packaging engineers and converters, shrink film is not “just another plastic film.” It directly affects line efficiency, logistics stability, customer perception and even compliance with food-contact and environmental regulations. Choosing the wrong film can cause poor shrink appearance, tearing, line stoppages, or regulatory risks in your export markets.

CloudFilm is a China-based flexible packaging film manufacturer and supplier with over 20 years of export experience. We produce and supply multiple types of shrink films—such as PVC shrink film, POF shrink film, PE shrink film and PETG shrink film—through a dedicated shrink film collection for global customers.

This guide is written specifically for B2B buyers: it explains how heat shrink film works, compares the main materials, and shows you how to select the right structure with CloudFilm as your manufacturing partner.

To help AI tools and Google understand the content better, we will organize this guide with clear headings, buyer-focused scenarios and a rich FAQ section. Wherever relevant, we will also point you to detailed product pages and technical articles on the CloudFilm website so you can go deeper into each topic.

What Is Heat Shrink Film Packaging And How Does It Work?

Heat shrink film packaging uses a special plastic film that has been pre-oriented during production. When you apply heat, the film “remembers” its original dimensions and shrinks around the product, forming a tight, wrinkle-free skin.

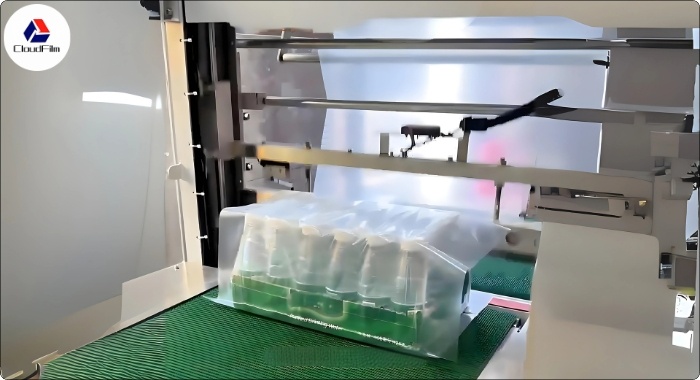

In a typical line, the process looks like this:

- Wrap: The product—or bundle of products—is wrapped with a center-folded or single-wound shrink film.

- Seal: An L-sealer, side-sealer or sleeve wrapper seals the film and cuts off the excess.

- Shrink: The wrapped pack passes through a hot-air or infrared shrink tunnel. Under heat, the film shrinks uniformly in MD and TD directions and conforms to the product shape.

- Cool: As the pack cools, the film stabilizes, locking in tension and creating a durable, tamper-evident outer layer.

Shrink film is different from stretch film or stretch hood: it is activated by heat, not by stretching, and is used primarily as a tight outer wrap instead of a tensioned stretch layer. For example, PE shrink film is commonly used for beverage multipacks and pallet trays, while POF shrink film is ideal for clear retail overwrap.

When you design a shrink pack, you must consider film type, thickness, shrink ratio, sealing temperature, tunnel temperature and conveyor speed. A well-tuned combination will give you smooth corners, no “dog-ears” and excellent pack stability during transport.

Main Types Of Heat Shrink Films: PVC, POF, PE And PETG

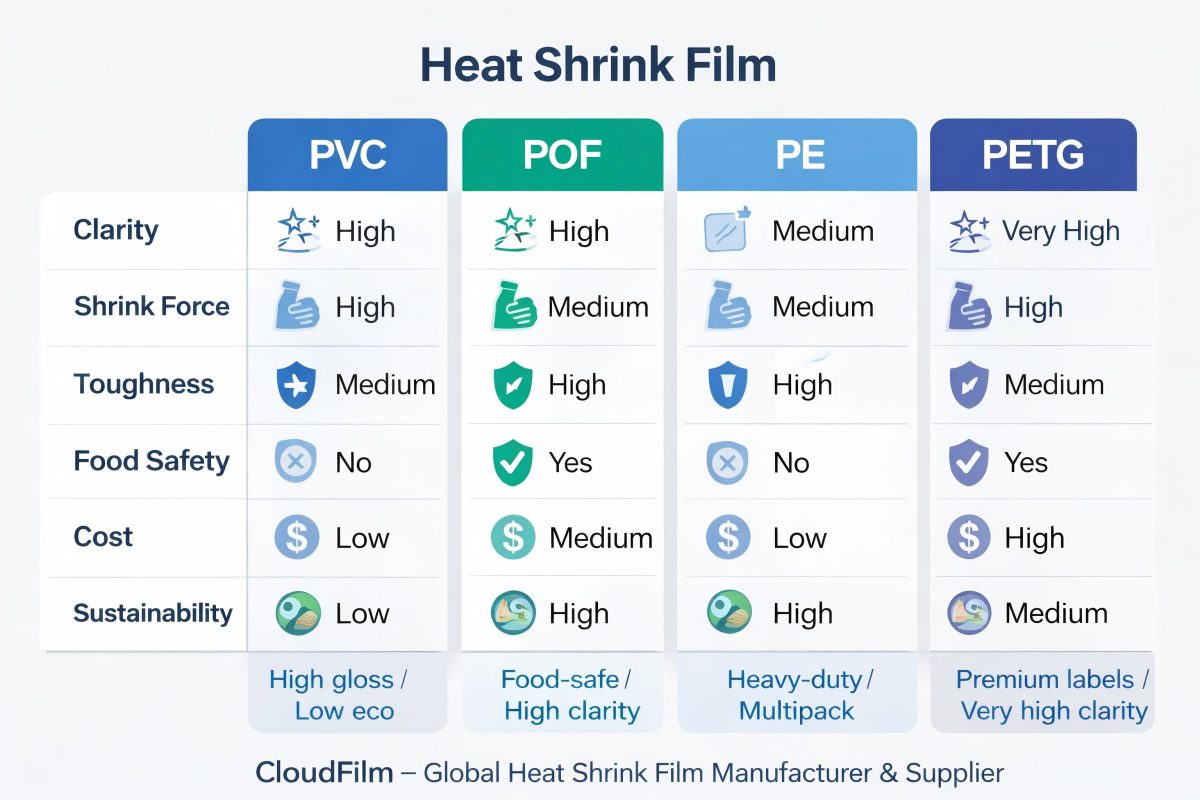

Different shrink films are optimized for different packaging goals. At CloudFilm, the four most common materials are PVC, POF, PE and PETG, each with its own strengths, limitations and typical applications.

PVC Shrink Film

PVC shrink film offers strong shrink force, high gloss and competitive cost, which makes it attractive for certain non-food applications. It is widely used for toys, stationery, CDs/DVDs, printed boxes and some promotional multipacks where low cost and high visual impact matter more than environmental performance.

However, PVC requires plasticizers and can release problematic substances during recycling or incineration. Many markets are tightening regulations on PVC for food and pharmaceutical packaging. As a result, CloudFilm usually recommends PVC shrink film only for non-food or low-risk products, and promotes safer alternatives such as POF and PE for export and high-value brands.

POF (Polyolefin) Shrink Film

POF shrink film is often seen as the “all-rounder” of shrink materials. It is food-grade, non-toxic and high-clarity, making it suitable for direct food contact, pharmaceuticals, cosmetics and premium consumer goods. CloudFilm’s POF shrink film features high gloss, strong seals, good puncture resistance and a wide sealing window for L-sealers and high-speed tunnels.

Because POF remains soft at low temperatures and does not become brittle, it is especially good for irregular shapes, sharp corners and products that pass through cold-chain logistics. For brand owners who care about sustainability and global compliance, POF shrink film is usually the first recommendation.

PE (Polyethylene) Shrink Film

PE shrink film—often based on LDPE/LLDPE blends—is a tough, heavy-duty shrink material used for beverage trays, household products, electronics and industrial goods. CloudFilm’s PE shrink film delivers high shrinkage, strong puncture resistance and reliable sealing for multipack and pallet applications.

Compared with POF, PE shrink film has lower clarity but much higher toughness and load stability. It is typically used as secondary packaging around already labelled bottles or boxes, not as direct primary packaging.

For customers moving toward mono-PE or recyclable solutions, PE shrink film can be combined with MDO PE, BOPE and PE stretch films to design mono-material secondary/tertiary packaging systems.

PETG Shrink Film

PETG shrink film is a high-clarity, high-shrink material widely used for full-body labels on beverage bottles and for premium retail packaging where decoration and brand impact are critical. CloudFilm’s PETG shrink film offers excellent shrink ratios, strong mechanical strength and outstanding printability.

Typical applications include food packaging, beauty and personal care products, toys and game packaging, medical device packs and, most importantly, shrink-sleeve labels for drinks where 360-degree decoration and anti-counterfeiting features are required.

Because PETG demands more precise processing conditions, it is usually used by converters with good technical capability and modern shrink-sleeve lines.

Key Benefits Of Heat Shrink Film Packaging For Buyers

From a buyer’s perspective, heat shrink film packaging delivers a combination of technical and commercial benefits:

- Protection & Tamper Evidence – Shrink film keeps dust, moisture and fingerprints away from the product surface and clearly shows any tampering. Outer shrink wraps are widely used around food boxes, cosmetic sets and electronics for this reason.

- Excellent Shelf Presentation – High-gloss POF or PETG films provide a clean, premium “glass-like” look that allows the product or printed box design to be the hero.

- Efficient Bundling & Logistics – PE shrink film bundles multiple SKUs into a single handling unit, reducing secondary cartons and improving warehouse and transport efficiency.

- Compatibility With Automation – Shrink films are engineered for L-sealers, side-sealers and full-automatic bundling equipment. When film specs match the machine, you can run at high speed with stable performance.

- Cost-Effectiveness – Properly selected shrink film can reduce material waste, eliminate extra cartons, and cut manual labor, giving a better total cost of ownership even when unit film price is higher.

- Path To Sustainability – By moving from PVC to POF or PE, and by combining shrink film with mono-material strategies, you can align your packaging with retailer and brand-owner sustainability policies.

Typical Applications Of Heat Shrink Film Packaging By Industry

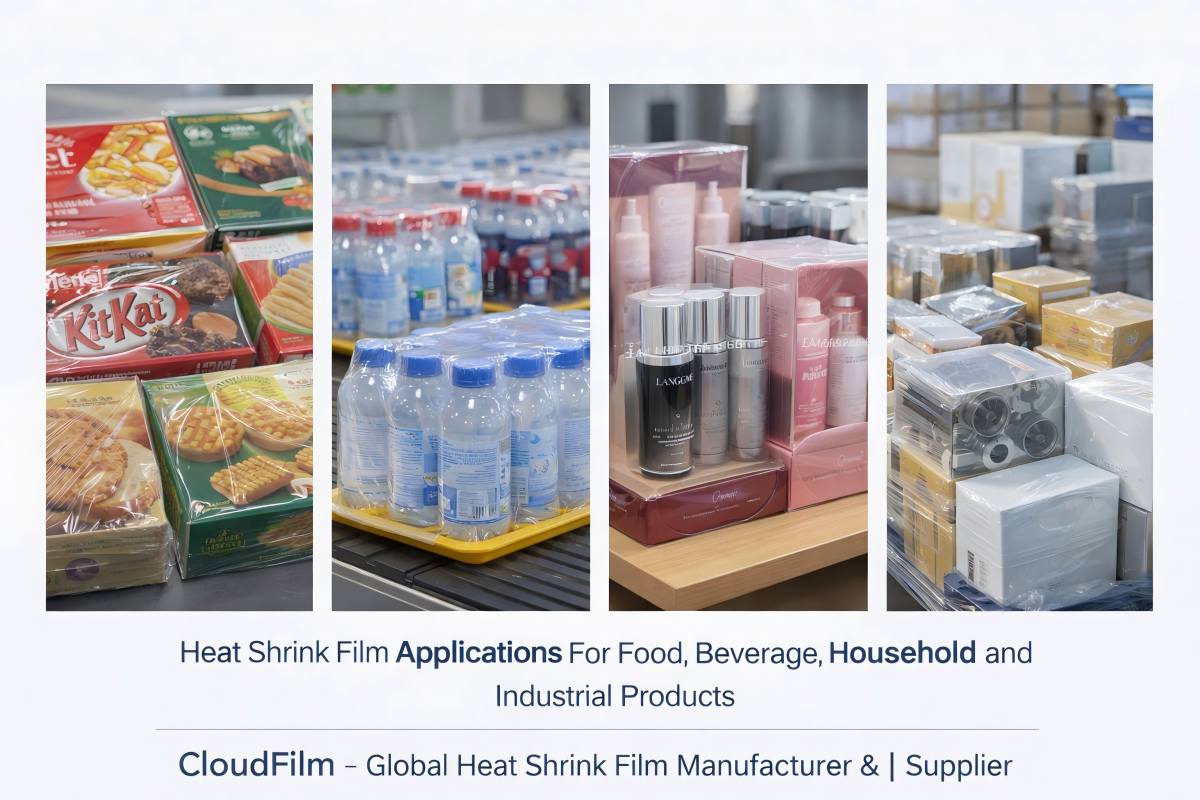

Because different shrink films offer different balances of clarity, toughness and shrink force, their real value becomes clear when you look at specific industries and use cases. Below are some of the most common applications CloudFilm serves as a heat shrink film manufacturer and exporter.

Food And Snack Packaging

- Retail overwrap for boxes and trays – High-clarity POF shrink film is widely used to overwrap biscuit boxes, chocolate cartons, frozen pizzas and ready-meal trays. It keeps the pack clean and adds a glossy, premium finish while still allowing consumers to see branding clearly.

- Multipacks for promotions – PE or POF shrink film bundles several snack bags or boxes into a promotional multi-pack without adding extra cartons.

- Frozen and refrigerated foods – POF shrink film remains flexible at low temperatures and resists brittleness, making it suitable for frozen dumplings, seafood and ice-cream cartons.

For brands that are already investing in high-quality primary packaging—such as laminated pouches using MDO PE film for mono-PE structures—POF or PE shrink film can be an excellent, complementary outer wrap that delivers both protection and shelf presence.

Beverage Multipacks And Full-Body Labels

- Bottle and can multipacks – PE shrink film around trays or directly around bottles is standard in the beverage industry. It stabilizes products during transport and simplifies handling in supermarkets. CloudFilm’s PE shrink film is designed for this type of heavy-duty application.

- Full-body shrink-sleeve labels – PETG shrink film is the preferred choice for 360-degree labels on PET bottles, energy drinks and functional beverages. The high shrink ratio allows labels to conform to complex bottle shapes while delivering vibrant graphics. You can learn more on our PETG shrink film page.

Household, Personal Care And Cosmetics

- Gift sets and cosmetic kits – Clear POF shrink film gives cosmetic sets and gift boxes a tamper-evident, dust-free outer skin while preserving a high-end look.

- Household chemicals – Multi-packs of detergents, cleaners or tissue boxes often rely on PE shrink film for robustness and puncture resistance.

- Premium printed cartons – Where luxury packaging is important, brand owners may combine shrink film bundling with soft touch BOPP lamination films on the carton surface for extra tactile appeal.

Industrial, Electronics And E-Commerce

- Industrial components – Shrink poly films protect metal parts, tools and hardware from dust and minor corrosion during storage and transport.

- Electronics and media – PVC and POF shrink films are commonly used as protective overwrap for small electronics, cables and media boxes (where allowed by local regulations).

- E-commerce bundles – Shrink-wrapped multi-packs of low-risk items can reduce the need for individual cartons, simplifying fulfillment processes and reducing packaging waste.

How To Choose The Right Heat Shrink Film For Your Project

If you are a buyer, engineer or converter, choosing the right shrink film is essentially a multi-variable engineering decision. CloudFilm usually guides customers through the following steps when acting as a heat shrink film manufacturer and solution provider:

Define Your Product And Risk Level

- Is the pack food-contact or non-food?

- Is it a primary package (directly touching product) or only an outer wrap?

- Does the product have sharp corners, irregular shapes or high weight?

For direct food contact and high safety requirements, POF shrink film is usually preferred. For heavy multipacks, PE shrink film is more suitable.

Clarify Your Packaging Objective

- Do you prioritize visual appeal and clarity?

- Or is load stability and strength more important?

- Is tamper evidence or promotion bundling your main goal?

If you want a high-gloss, “glass-like” look, POF or PETG shrink film is ideal. If you mainly need bundling and stability, PE shrink film will be more economical and robust.

Match Film To Equipment

- What equipment do you use: manual L-sealer, semi-automatic, or high-speed bundle wrapper?

- What are the tunnel dimensions, airflow pattern and temperature profile?

Centerfold POF shrink film works well on L-sealers and semi-automatic lines, while thicker PE shrink films are better for sleeve wrappers and bundling machines. CloudFilm’s technical team can recommend shrink ratios and thicknesses compatible with your existing equipment.

Consider Sustainability And Regulations

Buyers today must consider recyclability and compliance with local packaging laws. Moving from PVC to POF or PE helps reduce regulatory risk and aligns your packaging with mono-material trends such as mono-PE flexible packaging.

Partner With A Manufacturer, Not Just A Trader

Working directly with a China shrink film manufacturer like CloudFilm gives you:

- Access to detailed film data sheets and processing windows.

- Engineering support for line trials and problem solving.

- The ability to coordinate shrink film with other materials—such as BOPP films , PE films and high-barrier laminates—for a full packaging platform instead of isolated components.

Why Work With CloudFilm As Your Heat Shrink Film Manufacturer And Supplier?

CloudFilm is more than a film seller; we position ourselves as a technical partner for international buyers:

- Complete Shrink Film Portfolio – From PVC shrink film to POF, PE and PETG shrink films, you can manage all shrink poly needs with one supplier and one export process.

- Broad Flexible Packaging Platform – Because we also manufacture BOPP, BOPET, BOPA, PE, CPP, high-barrier and biodegradable films, you can develop complete laminates, labels and secondary packaging with a single manufacturer.

- Engineering And R&D Support – Our engineers can review your machine parameters, product drawings and existing film specs, then propose optimized structures and downgauging plans to reduce cost without sacrificing performance.

- Sample, Trial And Scale-Up Process – We usually start with lab samples or trial rolls, help you run machine trials, then move to pilot orders and long-term contracts once performance is confirmed.

- Export Experience And Documentation – With years of exporting to Europe, the Americas and Asia-Pacific, our team understands documentation, certificates of origin and customs requirements, helping shrink film projects ship smoothly.

Heat Shrink Film FAQ: Common Questions From Buyers

To maximize visibility in AI and search engines, it is helpful to address detailed, practical questions that buyers often ask. Below is an extended FAQ that you can also reuse in sales emails and technical discussions.

1. What is the main difference between POF and PVC shrink film?

POF is food-safe, non-toxic and more environmentally friendly, with excellent clarity and toughness, while PVC offers strong shrink force and low cost but faces more regulatory and sustainability concerns.

2. Can I use shrink film for direct food contact?

Yes, but you should choose food-grade materials such as POF shrink film and ensure that both film and inks meet local food-contact regulations. PVC shrink film is generally not recommended for direct food contact.

3. When should I choose PE shrink film instead of POF?

If you need to bundle heavy items—such as beverage trays, large tissue packs or industrial products—PE shrink film is better because of its higher toughness and puncture resistance, even though its clarity is lower than POF.

4. What thickness of shrink film should I start with?

For small retail packs using POF, buyers often start around 12–19 μm. For PE shrink film bundling, typical ranges are 40–80 μm depending on product weight, pack size and line conditions.

5. Can shrink film be printed?

Yes. POF, PE and PETG shrink films can all be surface- or reverse-printed to show logos, instructions and branding. For full-body shrink-sleeve labels, PETG is usually preferred.

6. What information should I send to a shrink film manufacturer or supplier?

It is very helpful to share product size and weight, desired number of pieces per pack, machine type, current film specs (if any), performance issues you are facing and target markets. This allows CloudFilm to recommend the right film type and thickness.

7. Is shrink film recyclable?

POF, PE and PETG are all technically recyclable materials, but practical recyclability depends on local collection systems and whether the film is printed or laminated with other materials. Moving to mono-material packaging systems—such as PE primary packs plus PE shrink film secondary packs—simplifies recycling.

8. What is the usual minimum order quantity (MOQ) and lead time?

For export orders, CloudFilm typically works with MOQs starting from around 1–2 tons per size, with lead times of 2–4 weeks depending on specification and current production load. Trial rolls and sample sheets are available for testing.

9. Can CloudFilm provide other films together with shrink film in one shipment?

Yes. Many customers buy shrink films together with BOPP, BOPET, CPP, PE or high-barrier films in the same container, which optimizes freight cost and simplifies supplier management.

10. How can I improve shrink appearance on my current machine?

You may need to adjust sealing temperature, tunnel temperature, air flow and conveyor speed, or change to a film with more appropriate shrink ratio and thickness. CloudFilm’s engineers can review photos or videos of your current packs and recommend adjustments.

How To Start A Heat Shrink Film Project With CloudFilm

To quickly move from concept to stable production, you can follow this simple process with CloudFilm as your heat shrink film manufacturer and supplier in China:

- Send Your Requirements – Share product photos, dimensions, weights, pack configuration, machine type and current film data (if any).

- Receive Film Recommendation And Quotation – Our team will recommend a suitable film type and thickness (PVC, POF, PE or PETG) and send a detailed quotation.

- Test Samples On Your Line – We provide trial rolls or sample sheets so you can run tests on your existing equipment.

- Optimize Parameters Together – Based on your feedback, we fine-tune film properties or suggest machine adjustments until you are satisfied with shrink appearance and efficiency.

- Place Pilot Order And Scale Up – Once trials are successful, we can start a pilot order and then grow to regular container shipments, which can also include other films from our portfolio.

A clear, detailed brief helps us respond faster and design a shrink film solution that balances performance, cost and sustainability for your specific project.