Introduction

From the oxygen-blocking layer in your food packaging, to the scratch-resistant protector on your smartphone screen, and the elegant trim on a luxury car interior, a key manufacturing technology is behind the superior performance of these products: the film lamination process.

Simply put, it’s like a “material magician” that bonds two or more different film materials together using adhesives or physical means, creating a new composite material that combines the best features of each.

This ultimate guide, prepared by CloudFilm, will take you from the ground up to understand the film lamination process comprehensively and in-depth. Whether you are a newcomer to the industry, a seasoned engineer, or a procurement decision-maker looking for solutions, you will find the answers you need right here.

Core Principles and Objectives of Film Lamination

1.1 Core Principle: The Material Science of 1+1 > 2

The essence of film lamination is to bond at least two substrates (such as plastic films, aluminum foil, paper, etc.) together through specific technical means. Its core lies in “interfacial bonding,” utilizing the chemical bond strength of adhesives or physical van der Waals forces to form a stable, solid whole between different materials.

This process is not merely a simple “sticking” but a precise physicochemical process, with the ultimate goal of creating a composite material whose performance surpasses any of its individual components.

1.2 Core Objectives: Why Do We Perform Lamination?

The film lamination process is typically undertaken to achieve one or more of the following key objectives:

- Enhanced Barrier Properties 🛡️: This is one of the primary goals. For example, laminating a layer of extremely thin aluminum foil onto a plastic film can dramatically improve the packaging’s barrier against oxygen, water vapor, and light, thereby extending the shelf life of food and pharmaceuticals.

- Improved Physical Properties 💪: Laminating a flexible film with a high-strength material (like PET or nylon) can significantly increase the final product’s tensile strength, abrasion resistance, puncture resistance, and dimensional stability.

- Improved Aesthetics and Texture ✨: Through lamination, a variety of visual effects and hand-feels can be achieved, such as matte, high-gloss, metallic, and textured finishes, greatly enhancing the product’s added value and brand image.

- Special Functionality 🔬: For instance, laminating a heat-sealable film (like PE or CPP) with a film that has good printability (like BOPP) allows for exquisite printing while also enabling convenient heat-sealing. Films with anti-static, electromagnetic shielding, or other functions can also be incorporated.

- Reduced Overall Cost 💰: In some cases, a layer of expensive functional film (like high-barrier EVOH) can be laminated with an inexpensive support film (like PE), effectively controlling material costs while ensuring performance.

Detailed Breakdown of Main Film Lamination Process Types

Depending on the adhesive type and lamination method, film lamination processes are mainly divided into the following categories. The choice of process depends on product requirements, production efficiency, and cost budget.

| Process Type | Core Principle | Advantages | Disadvantages | Main Application Areas |

|---|---|---|---|---|

| Dry Lamination | A solvent-based adhesive is coated onto the first substrate, passed through an oven to evaporate the solvent, and then thermally bonded to the second substrate. |

High bond strength, wide range of applicable materials, mature technology. |

Uses organic solvents, leading to VOC emissions and safety concerns; high energy consumption and cost. |

High-demand food packaging, retort pouches, aluminum foil lamination. |

| Wet Lamination | A water-based adhesive is coated onto the first substrate and immediately bonded to the second substrate while still wet, then dried in an oven. |

High speed, low cost, environmentally friendly (solvent-free). |

One substrate must be porous (e.g., paper) to allow water evaporation, limiting its application. |

Paper-plastic lamination, paper-aluminum lamination (e.g., Tetra Pak), some textiles. |

| Solventless Lamination | Uses 100% solid-content solventless adhesives, which are coated and directly bonded to another substrate without drying. |

Extremely eco-friendly (zero VOC), low energy consumption, high running speed, low overall cost. |

High initial equipment investment, requires high precision in process control. |

Becoming the mainstream trend for food and pharmaceutical packaging, with increasingly widespread applications. |

| Extrusion Lamination | Molten plastic resin (e.g., PE, PP) is extruded directly from a T-die onto a substrate, acting as an adhesive layer to thermally bond another substrate. |

Extremely high production efficiency, can be produced in-line, cost-effective. |

The laminated layer is thicker, transparency and flexibility may be inferior to other processes. |

Heavy-duty sacks, cement bags, book covers, waterproof materials. |

| Hot Melt Lamination | Uses solid hot-melt adhesives, which are heated to melt, applied, and then solidified upon cooling to bond. |

Extremely fast, 100% solid content, solvent-free. |

Generally poor heat resistance, bond strength may not be as good as other methods. |

Fast-moving consumer goods labels, hygiene products, shoe materials, some automotive interiors. |

Ubiquitous Applications: The Value of Film Lamination

The film lamination process is found in almost every aspect of our production and daily life, with its value reflected in providing critical material solutions for various industries.

- 🍔 Packaging Industry:

- Food Packaging: This is the largest application market. Chip bags (BOPP/Metallized PET/PE), coffee pouches (PET/Aluminum Foil/PE), and cling films (PE/EVOH/PE) achieve oxygen barrier, moisture resistance, aroma retention, light blocking, and heat-sealability through lamination.

- Pharmaceutical Packaging: Blister packs (PVC/Aluminum Foil) and medicine sachets have extremely high requirements for barrier properties and safety, making lamination the preferred choice.

- Cosmetic Packaging: Detergent pouches, facial mask sheets, etc., require good barrier properties and drop resistance.

- 🚗 Automotive Industry:

- Interior Parts: Dashboards, door panels, and center consoles often use laminated materials like PVC/ABS or TPO/Fabric to achieve aesthetics, durability, ease of cleaning, and a comfortable feel.

- Automotive Glass: Laminated safety glass (Glass/PVB/Glass) is a typical lamination process aimed at improving safety.

- 📱 Electronics & Optoelectronics Industry:

- Display Screens: The touchscreens of mobile phones and tablets are often laminated with a protective film (e.g., PET/Hard Coating/Silicone) to provide scratch resistance, anti-glare, and anti-fingerprint properties.

- Solar Panels: Backsheets (e.g., PET/Fluoropolymer/Adhesive) and encapsulation films (EVA, POE) are key laminated materials that protect the solar cells and ensure their long-term stable operation.

- 🏠 Construction & Industrial Fields:

- Decorative Materials: High-Pressure Decorative Laminates (HPDL) used for furniture, cabinets, and wall panels are wear-resistant, heat-resistant, and easy to clean.

- Industrial Materials: Waterproof membranes, tent fabrics, and advertising lightbox fabrics achieve properties like waterproofing, UV resistance, and high strength through lamination.

Core Equipment and Process Overview

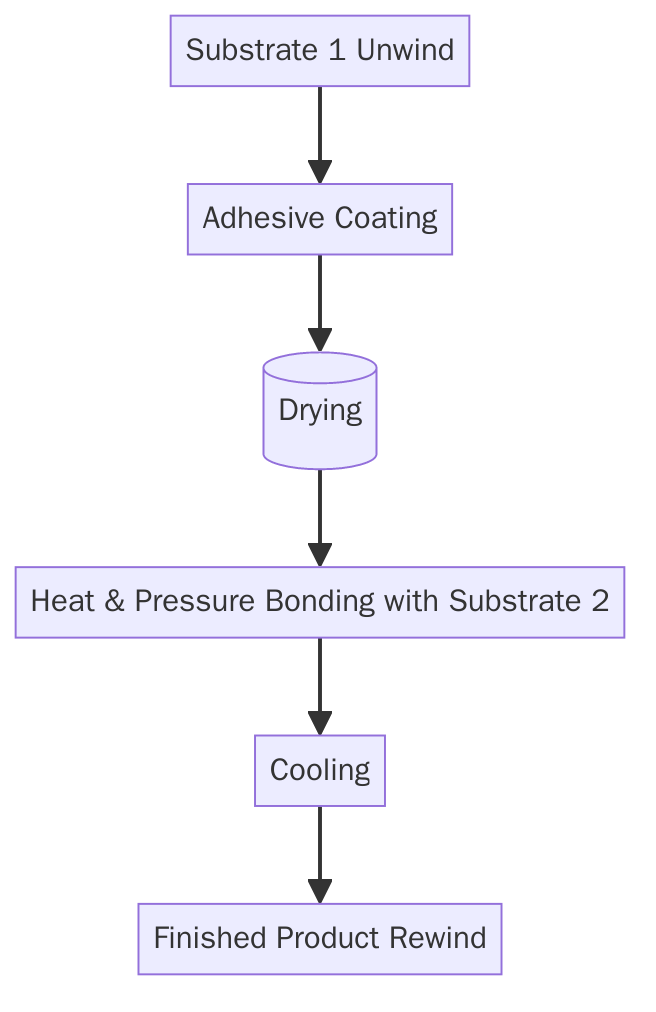

A complete film lamination production line typically consists of the following core components. Taking the most complex dry lamination line as an example:

- Unwinding Systems: Two or more unwinders for smoothly and precisely feeding the substrate films to be laminated. Usually equipped with tension control and web guiding systems.

- Coating Station: Applies the adhesive evenly onto the first substrate. Common coating methods include gravure roll coating, knife coating, and air knife coating. Coating precision directly impacts product quality.

- Drying System: (For dry lamination) A long heated oven tunnel used to completely evaporate and exhaust the solvent from the adhesive. The temperature zoning and air volume control of the oven are critical.

- Lamination Nip: Consists of a heated steel roll and a pressure rubber roll. The coated and dried (if required) substrate is bonded with the other substrate here under heat and pressure.

- Rewinding System: Winds the finished laminated film neatly and smoothly into a roll. It also requires precise tension control to ensure the roll is flat and wrinkle-free.

- Auxiliary Systems: Include adhesive supply systems, tension control systems, web guiding systems, cooling systems, and online inspection systems (e.g., defect detection).

Basic Process Flow: Substrate 1 Unwind → Adhesive Coating → (Drying) → Heat & Pressure Bonding with Substrate 2 → Cooling → Finished Product Rewind.

Challenges, Quality Control, and Future Trends

5.1 Common Challenges and Key Quality Control Points

The lamination process is not always smooth sailing. Common issues include: bubbles, wrinkles, white spots, insufficient peel strength, and odor. Strict quality control is essential for producing qualified products.

- Incoming Material Inspection: Check substrate thickness, tension, surface tension (corona level), and cleanliness.

- In-Process Control: Precisely control adhesive coating weight, oven temperature/airflow, lamination temperature/pressure, and tension in each section.

- Finished Product Inspection: Test peel strength, heat seal strength, barrier properties (Oxygen/Water Vapor Transmission Rate), and inspect for visual defects.

5.2 Future Trends

With technological advancements and changing market demands, the film lamination process is evolving towards greater efficiency, environmental friendliness, and intelligence.

- Green and Eco-Friendly is the Main Theme 🌿: Solventless lamination and water-based adhesives will accelerate the replacement of traditional solvent-based processes to meet increasingly stringent environmental regulations and sustainability goals. Recyclable and degradable mono-material composite structures are a hot R&D topic.

- Functionalization and High-Performance: There is a growing market demand for composite films with ultra-high barrier, antimicrobial, self-healing, and smart-indicating (e.g., freshness) functions, driving the development of new materials and processes.

- Intelligence and Digitalization 🤖: Industry 4.0 technologies are being integrated into lamination lines. Through IoT sensors, big data analytics, and AI algorithms, real-time monitoring, predictive maintenance, and adaptive control of the production process can be achieved, thereby improving efficiency, reducing waste, and ensuring quality stability.

- Process Innovation: The combination of surface modification technologies like nanocoating and plasma treatment with lamination processes is expected to enhance interfacial bonding at the molecular level, creating composite materials with superior performance.

Conclusion

The film lamination process is a manufacturing technology that appears simple but actually involves profound materials science and precision engineering. By cleverly “combining materials,” it greatly expands the application boundaries of single materials, becoming an indispensable part of modern industry.

From packaging that ensures the safety of our daily food, to consumer goods that enhance our quality of life, and to key components that drive cutting-edge technology, the value of the film lamination process is everywhere. Looking ahead, with the waves of green development, functionalization, and intelligence, this technology is set to shine in even more fields.

CloudFilm is always committed to being at the forefront of film lamination technology, providing customers with the most advanced materials, processes, and solutions. If you have any questions or needs in the field of film lamination, please feel free to contact us.

FAQs (Frequently Asked Questions)

Q1: What is the most critical parameter in the film lamination process?

A: This depends on the specific process, but a few parameters are common. First is tension control; unstable tension leads to wrinkles and curling. Second is coating weight, which directly determines bond strength and cost. For dry lamination, oven temperature and airflow are crucial as they affect solvent residue and bonding effectiveness. For all processes, lamination pressure and temperature are also key to ensuring a good bond.

Q2: How do I choose between solventless and dry lamination?

A: This is a classic trade-off between cost, performance, and environmental impact.

- Choose solventless lamination if: Your primary goals are environmental compliance, reducing long-term operating costs (energy, solvent costs), and achieving high production speeds. It is very suitable for most food and pharmaceutical packaging.

- Choose dry lamination if: You need to laminate certain special materials (like aluminum foil, paper), have a limited budget for initial equipment investment, or have special requirements for extreme heat/chemical resistance. Despite VOC issues, its maturity and adaptability remain strong.

Q3: Why are there bubbles in my laminated product?

A: Bubbles are one of the most common problems in lamination, and the causes can be complex. Main reasons include: 1) Uneven adhesive coating or impurities in the adhesive; 2) Insufficient drying, where residual solvent volatilizes under heat; 3) Insufficient or uneven pressure from the lamination rollers; 4) Insufficient surface tension of the substrate, leading to poor wetting; 5) High ambient air humidity. A systematic investigation is needed, looking at the “Man, Machine, Material, Method, Environment” (5M) aspects.

Q4: What is the difference between film lamination and coating?

A: This is an excellent question. The core difference lies in the number of layers and the materials.

- Coating: Is the process of applying a very thin layer of a liquid (a coating, adhesive, etc.) onto the surface of a single substrate to form a functional layer. For example, coating a layer of PVDC onto a BOPP film to increase its barrier properties. It is essentially still “one” layer of material.

- Lamination: Is the process of bonding two or more pre-formed, independent solid film materials together using adhesives or heat and pressure to create a “new” material with a multi-layer structure. For example, bonding a PET film and an aluminum foil together. It deals with “multiple” layers of material.