Introduction

Cellophane film has long been regarded as a go-to packaging material for its unique combination of properties that make it both versatile and eco-friendly. Originating from regenerated cellulose, cellophane film has been used across various industries for decades, continually proving its value due to its aesthetic qualities, protective features, and biodegradability. This blog will delve into the properties, types, and uses of cellophane, exploring why it remains a highly popular packaging solution today.

Key Properties of Cellophane Film

One of the standout qualities of cellophane film is its excellent clarity and transparency, making it an ideal choice for packaging that requires a clear view of the product. This feature is highly valued in industries like food packaging, where the visual appeal of products is crucial in attracting customers. Moreover, cellophane has a natural glossiness that enhances its overall aesthetic appeal.

Aside from its visual qualities, cellophane is also known for its tensile strength and flexibility, which allow it to be used in various forms of packaging, from wrapping small items to covering large industrial supplies. Despite its lightweight nature, it provides robust protection to the items inside, helping to maintain product integrity during handling and shipping.

Another major advantage of cellophane film is its heat resistance. It can withstand sterilization processes, which makes it suitable for food packaging, where high temperatures are often used. Unlike other plastic films, cellophane does not deform under high heat, ensuring the product remains intact and safe.

Perhaps most importantly in today’s sustainability-focused world, cellophane film is biodegradable. It breaks down quickly in the soil without leaving harmful residues, unlike petroleum-based plastics that can take centuries to degrade. This makes it a more environmentally responsible choice, aligning with growing consumer demand for greener packaging alternatives.

Types of Cellophane Film

Cellophane film comes in various types, each tailored to specific applications. Understanding these variations can help industries choose the right kind of cellophane based on their particular needs.

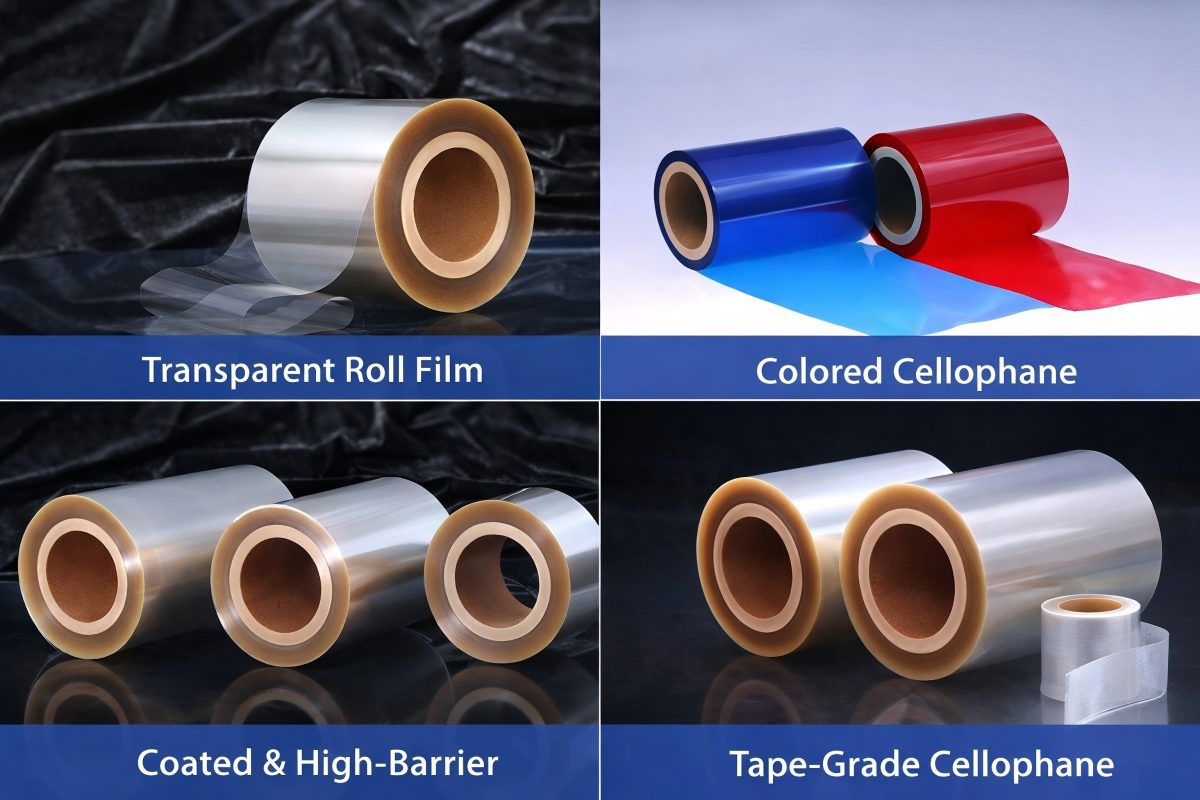

Transparent Roll Cellophane Film

This is one of the most common forms of cellophane film. It is available in multiple specifications and is widely used in both food packaging and the packaging of industrial supplies.

The material’s high transparency and glossy finish make it ideal for showcasing the contents while providing protective qualities. Its flexibility allows it to be used in both manual and automated packaging processes.

Colored Cellophane Film

Produced using advanced dyeing techniques, colored cellophane is available in a wide range of vibrant hues that do not fade over time. This type is commonly used for the colorful packaging of high-end products, including food, confectionery, and even fireworks. T

he ability to combine functionality with striking visual appeal makes colored cellophane a favorite in industries that value both form and function.

Coated Cellophane Film

Coated cellophane film is essentially regenerated cellulose film that has been treated with a PVDC (polyvinylidene chloride) coating on both sides. This enhances its heat sealability, barrier properties, and fragrance retention. Coated cellophane is ideal for packaging applications where high moisture, oxygen, or aroma barrier properties are required, such as in the food, pharmaceutical, and electronics industries. The PVDC coating also makes it more resistant to chemicals and oils, extending its usability in various applications.

Tape Cellophane Film

This specialized form of cellophane film is designed specifically for the production of adhesive tapes. Its properties include excellent adhesion, good unfolding performance, and low tear resistance, making it perfect for creating strong, durable tapes used in various industries, including electronics and packaging.

High-Barrier Heat-Sealing Regenerated Cellulose Film

A more advanced type of cellophane, this film comes coated with PVDC on one or both sides, giving it excellent barrier properties against water vapor and gases. It is often used in applications where a high level of protection is needed, such as in food packaging, where keeping moisture and air out is crucial to preserving freshness.

This type of cellophane is also notable for its anti-static properties, making it suitable for electronics packaging. Additionally, it offers resistance to oils and greases, enhancing its versatility in various industries.

Uses of Cellophane film in Different Industries

Food Packaging

The food industry is one of the largest users of cellophane film due to its non-toxic, odorless, and transparent properties. It is commonly used to package snacks, cereals, confectionery, and baked goods, among other items. Cellophane’s barrier properties help extend the shelf life of food products by protecting them from moisture and air exposure.

Its sterilizable nature also makes it ideal for ready-to-eat food packaging, where hygiene is a critical concern.

Pharmaceutical and Medical Packaging

Cellophane’s sterility and protective qualities have made it an important material in the pharmaceutical and medical industries. It is often used to package medical devices, medications, and diagnostic products. Its heat resistance allows for sterilization processes, ensuring that the packaging remains uncontaminated and safe for medical use.

Electronics and Automotive Industries

In the electronics and automotive sectors, cellophane is used to protect sensitive components during transport and storage. Its anti-static properties and chemical resistance make it ideal for wrapping electronic parts that are prone to static discharge or damage from environmental exposure.

Similarly, in the automotive industry, it is used to protect various parts and components from scratches and dust.

Stationery and Hygiene Products

Cellophane’s clarity and durability have made it a popular choice for packaging stationery, hygiene products, and even toys. Its aesthetic qualities enhance the visual appeal of these products while its protective features ensure they remain in good condition during storage and transit.

Environmental Benefits of Cellophane Film

In an age where environmental sustainability is a growing concern, cellophane film stands out as an eco-friendly alternative to many plastic-based packaging materials. Derived from wood pulp, cellophane film is naturally biodegradable, breaking down in soil within a few weeks to a few months, depending on environmental conditions. This reduces waste and minimizes the impact on landfills and oceans compared to petroleum-based plastics.

Furthermore, cellophane film can be composted, providing an added benefit for businesses and consumers looking to minimize their environmental footprint. Its renewable origin from plant materials further enhances its reputation as a sustainable packaging solution.

Conclusion

Cellophane film remains a highly versatile, durable, and eco-friendly packaging material that has stood the test of time. Its wide range of applications across industries, from food to electronics, coupled with its environmental benefits, makes it an appealing choice for businesses looking to balance performance with sustainability.

With advancements in coating technologies and new formulations such as high-barrier cellophane film, this material continues to evolve, offering even more specialized solutions to meet the demands of modern packaging. For industries seeking an effective yet responsible packaging option, cellophane remains a valuable and adaptable material that is likely to continue its legacy well into the future.

If you are evaluating cellophane for your next project, you can start by reviewing CloudFilm’s Cellophane Film and Biodegradable Film pages, then contact our team for a tailored proposal and free quotation.

FAQ – Cellophane Film & CloudFilm Solutions

Q1. What is cellophane film made from?

Cellophane film is made from regenerated cellulose, typically derived from wood pulp or other plant-based sources. It is not a petrochemical plastic, which is why it can biodegrade under appropriate conditions.

Q2. Is CloudFilm’s cellophane film biodegradable and food-contact safe?

CloudFilm’s cellophane is part of its biodegradable film range and is designed for food, cosmetics and industrial wraps. Depending on the grade, it can meet typical food-contact requirements when used correctly; detailed compliance information is available on request and on the Cellophane Film product page.

Q3. How does cellophane compare with PLA and other biodegradable films?

Cellophane provides excellent clarity, stiffness and breathability, while PLA films are often used where higher heat resistance or specific compostability standards are required. Many customers combine cellophane with PLA Film

or mono-material PE/BOPE structures to create a balanced sustainable packaging portfolio. CloudFilm can advise which route is more suitable for your product.

Q4. What roll sizes and specifications can CloudFilm supply for cellophane?

CloudFilm can customize thickness, width, roll diameter and core size according to your converting equipment. Typical thickness ranges cover common food and gift-wrap applications, and trial rolls can be arranged before mass orders.

Q5. Can cellophane be heat-sealed or laminated with other films?

Yes. Base and coated cellophane can be laminated with PE, BOPE, PET, CPP and other films to build structures with higher seal strength or barrier. For easy-opening lids or sachets, CloudFilm also offers complementary Easy Tear Film and Easy Peel Film solutions.

Q6. How can I start a project with CloudFilm using cellophane film?

You can email or submit a form with basic information: product type, annual demand, target markets, desired structure (mono cellophane or laminates), special requirements (barrier, easy-open, eco claims) and any existing specs. CloudFilm will respond with recommended grades, trial proposal and quotation, often combining cellophane with other films such as Food Packaging Film where helpful.