What Is Stretch Film?

Stretch film (also called stretch wrap or pallet wrap) is a highly stretchable LLDPE-based plastic film used to bundle and stabilize products, usually on pallets, without using heat. When tension is applied during wrapping, the film tries to return to its original shape, generating a “memory” force that pulls the load together and keeps it tight during handling, transport and storage.

Most stretch films on the market are made from linear low-density polyethylene (LLDPE) and other PE blends. Compared with traditional shrink film, stretch film:

- Does not need a heat tunnel – it is applied cold, using hand tools or automatic stretch wrapping machines.

- Uses less energy – no burners or tunnels, which reduces operating cost and improves safety.

- Is more elastic than shrink film – it can accommodate movement and vibration during transport while still holding the load.

For B2B buyers, stretch film is one of the most cost-effective ways to protect products from dust, moisture and shifting damage while moving goods from factory to warehouse and then to the final customer.

CloudFilm focuses on PE-based films and offers PE stretch film, stretch-type PE rolls and related pallet packaging films as part of its PE film portfolio for global customers.

Main Roles Of Stretch Film

- Unitization – combine many cartons, bags or buckets into one stable shipping unit.

- Protection – keep products clean, avoid splash, dust, rain or condensation.

- Security – make tampering more obvious and discourage pilferage.

- Branding & Identification – use colored or printed stretch film to mark different product lines, export markets or production batches.

Because of these roles, stretch film is used daily by manufacturers, logistics companies, distributors and retailers worldwide.

Key Benefits Of Stretch Film In Modern Logistics

From a logistics and supply-chain management view, stretch film is not just “plastic around the pallet”. When selected and applied correctly, it directly contributes to:

- Load Stability And Damage Reduction

- Properly wrapped pallets can withstand vibration, braking, cornering and stacking. Fewer cartons collapse or slide, which reduces claims, returns and re-picking costs.

- Cost Control

- Lower material cost per pallet compared with many shrink solutions.

- Less secondary packaging such as straps or corner boards in some applications.

- Lower labor cost when using automatic or semi-automatic stretch wrappers.

- Operational Efficiency

- Stretch wrapping is easy to integrate at the end of the packing line. With the right machine and film, you can standardize wrapping patterns, film consumption per pallet and cycle times.

- Cleanliness And Moisture Protection

- The film forms a continuous skin around products, keeping out dust and splash water. For sensitive goods and export shipments, this is especially important.

- Sustainability Opportunities

- Because stretch film is usually made of mono-material PE, it is easier to collect and recycle compared with complex multi-material packaging. Many end users are now looking for downgauged, high-performance stretch films that achieve the same load stability with less plastic.

- Flexibility Across Different Products

- One grade of stretch film can often cover many SKUs with similar load characteristics, making inventory management simpler for distributors and end users.

For these reasons, professional buyers often treat stretch film as a strategic packaging component and work closely with a stretch film manufacturer or supplier to balance performance, cost and sustainability.

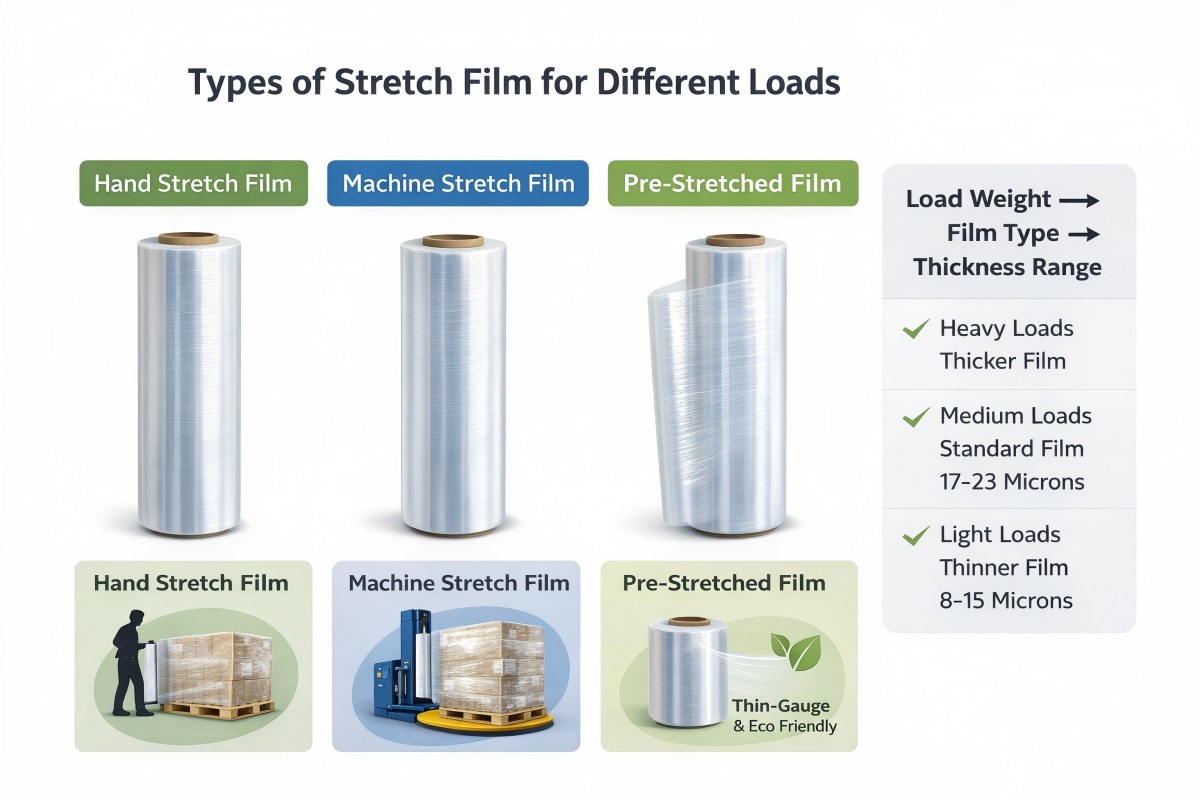

Common Types Of Stretch Film (Hand, Machine & Special Grades)

Choosing the right stretch film starts with understanding the main types available on the market.

Hand Stretch Film

Hand stretch film is designed for manual wrapping using simple dispensers or just by hand. It is ideal for:

- Low to medium volume operations

- Very large or irregular loads that cannot go through a machine

- Re-wrapping or repair work in the warehouse

Key features:

- Usually narrower widths (e.g. 450–500 mm)

- Moderate thickness to balance strength and ease of use

- Good cling to stay in place without additional tape

Machine Stretch Film

Machine stretch film is engineered for semi-automatic or fully automatic stretch wrapping machines. It is the best option for:

- Medium to high throughput logistics centers

- Manufacturers with stable pallet sizes and standardized loads

- Operations that want consistent, repeatable wrap quality

Typical characteristics:

- Higher stretch potential (pre-stretch 200–300% or more)

- Optimized coefficient of friction for smooth unwinding

- Precise roll dimensions for trouble-free operation on turntable, rotary arm or ring-type wrappers

CloudFilm’s PE stretch film is available in both hand and machine grades, tailored to different wrapping equipment and load profiles.

Pre-Stretched Film

Pre-stretched film is stretched during production and wound under controlled tension. For the end user, this offers:

- Lower effort for operators – less force is needed to apply the film

- More consistent film usage per pallet – easier to standardize

- Potential downgauging – use thinner film while maintaining performance

It is especially helpful when you want to reduce operator fatigue or ensure better wrap consistency in manual operations.

Cast vs Blown Stretch Film

From a process perspective, stretch film can be produced by cast film or blown film extrusion, each with its own characteristics:

- Cast stretch film

- Very good clarity and gloss

- Smooth and quiet unwinding

- Excellent thickness uniformity

- Blown stretch film

- Higher puncture resistance and toughness

- Better performance on loads with sharp corners

- Typically a bit noisier and with slightly lower clarity

When you discuss your project with a stretch film manufacturer, it is useful to mention whether you prioritize optics or toughness; this can influence the choice between cast-type and blown-type structures.

Special Stretch Films (Colored, UV, High-Performance)

Depending on your application, you may also consider:

- Colored / Opaque stretch film – for concealing high-value goods or coding different product categories.

- UV-stabilized stretch film – for long-term outdoor storage, protecting both the film and the goods from sunlight degradation.

- High-performance thin-gauge stretch films – reduced thickness but enhanced strength, helping you cut plastic consumption while keeping load stability.

Industry-Specific Applications Of Stretch Film

Stretch film is used across many industries. Below are some of the most common application scenarios.

Logistics & Warehousing

- Palletizing mixed cartons from multiple production lines

- Picking and consolidating e-commerce orders

- Temporary storage and cross-docking operations

Here, the primary goal is to keep pallets stable and scannable while moving quickly through the supply chain.

Manufacturing (Food, Beverages, Consumer Goods)

Producers of snacks, beverages, personal care and household products usually pack goods into cartons or shrink bundles first, and then use stretch film as the final outer layer on pallets.

For users who also need heat shrink solutions inside the line, CloudFilm supplies PE shrink film and POF shrink film in addition to stretch film, allowing a one-stop flexible packaging solution.

Building Materials, Chemicals & Resins

Bags of cement, tiles, resin pellets and chemical drums are heavy and often have sharp edges. Stretch film used in these sectors must provide:

- High puncture resistance

- Strong holding force

- Compatibility with stretch hood film in some plants

For more demanding loads, many customers combine conventional stretch film with stretch hood film to enhance weather resistance and stacking stability.

Agriculture & Horticulture

In agriculture, stretch film is used to secure:

- Fertilizer and feed sacks on pallets

- Seed, agrochemical and greenhouse material shipments

- Horticulture and flower boxes for export

Together with silage film and other PE films, it creates a complete PE packaging system around the farm-to-market chain.

E-Commerce & Retail Distribution

For omni-channel retailers and 3PLs, stretch film helps:

- Stabilize pallets of mixed SKUs going to different stores

- Protect returned goods while they are checked and re-sorted

- Consolidate seasonal promotion packs and point-of-sale materials

In these applications, thin-gauge, high-clarity film is often preferred to keep barcodes and labels visible.

How To Choose The Right Stretch Film (Step-By-Step)

Selecting the right stretch film is easier if you follow a structured process.

Step 1: Define Your Load And Pallet

Clarify:

- Load weight (per pallet)

- Load dimensions and pallet type

- How uniform the load is (full cartons vs irregular shapes)

- Whether there are sharp edges or corners

Step 2: Define Your Logistics Conditions

Ask:

- How many times will the pallet be handled (forklift movements, transfers)?

- Will it be shipped domestically only, or exported by sea?

- Will pallets be stacked, and how high?

- Indoor storage only or also outdoor storage?

More demanding conditions usually require stronger film, higher pre-stretch and/or more wrap coverage.

Step 3: Match Film Type And Thickness

In general:

- Hand stretch film – for low volume or mixed, irregular loads

- Machine stretch film – for medium/high volume with standard pallets

- Pre-stretched film – for better film control and reduced operator fatigue

Thickness (gauge) should be chosen according to load weight and sharpness. Heavy, high-value products need thicker and tougher film; lighter loads can use downgauged film to save material.

Step 4: Consider Film Performance & Resin Quality

Key parameters include:

- Stretchability and holding force

- Puncture resistance

- Clarity and cling behaviour

- Consistency from roll to roll

These are strongly influenced by the PE resin formulation and process control. Working with a manufacturer that also makes broader PE packaging films

can help you get a more optimized structure and better technical support.

Step 5: Choose Hand Vs Machine Wrap Method

If your volume is growing, you should evaluate when to upgrade from hand wrapping to machine wrapping. Automatic wrappers:

- Reduce operator fatigue and variability

- Control film usage more accurately

- Can be optimized together with PE stretch film and PE roll slit to the right width.

Step 6: Validate With Trials And Data

Before a full roll-out:

- Run line trials under real production conditions

- Measure film usage per pallet

- Check load stability after simulated transport

- Collect feedback from warehouse and logistics teams

Professional suppliers (like CloudFilm) can support you with film samples, on-site or remote technical suggestions, and data-driven optimization.

Working With A Stretch Film Manufacturer And Supplier

For B2B projects, the quality of your cooperation with a stretch film manufacturer has a direct impact on packaging cost, damage rate and customer satisfaction.

What To Look For In A Stretch Film Supplier

When evaluating potential suppliers, consider:

- Manufacturing capability – Do they extrude PE film themselves, or mainly trade finished rolls? Manufacturers with their own lines, like CloudFilm, can better control resin selection and film consistency.

- Range of PE films – Do they only offer stretch film, or a wider PE film range that includes shrink film, protective film, silage film, etc.? A broader range gives more flexibility when optimizing your whole packaging system.

- Technical support – Can they analyze your pallets, film consumption and line conditions, then propose concrete improvement measures?

- Export experience – For overseas buyers, it is important that the supplier understands pallets, container loading, documentation and trade terms.

Information You Should Share With The Manufacturer

To get a precise recommendation and quotation from a stretch film OEM supplier, prepare:

- Typical pallet size, weight and load pattern

- Current film type, thickness and wrap pattern (number of rotations)

- Problems you are facing (film breaks, corners puncturing, pallet collapse, etc.)

- Annual consumption or estimated monthly usage

With this data, a professional stretch film manufacturer in China can quickly shortlist 1–2 suitable grades, suggest downgauging opportunities and provide roll sizes that match your equipment.

Why CloudFilm For Stretch Film Projects?

As a flexible packaging film manufacturer since 2002, CloudFilm has long-term experience in:

- PE stretch film for hand and machine use

- PE roll film that can be slit into stretch-type rolls

- Stretch hood film and shrink films for comprehensive pallet packaging

- Technical support across cast and blown PE films

Global buyers can work with CloudFilm as an OEM or private-label supplier, combining reliable film quality with responsive service and clear communication.

Stretch Film Vs Other Pallet Packaging Options

When optimizing pallet packaging, stretch film is often compared with:

- Shrink Film

- Requires heat shrink tunnels

- Offers very tight, form-fitting packages

- Often used for retail-visible multipacks and bundles

- CloudFilm supplies both PE shrink film and POF shrink film for customers who need high shrink force or retail presentation in addition to pallet wrapping.

- Stretch Hood Film

- Applied as a tubular hood over the pallet

- Provides excellent weather resistance and high load stability

- Requires dedicated stretch hood equipment

- It is often used together with stretch film in demanding applications such as chemicals, bricks and resin bags.

- Straps And Corner Boards

- Useful for certain rigid loads

- Provide strong top-to-bottom compression

- Do not protect from dust or splash by themselves

In many cases, the most efficient solution is a hybrid system: stretch film as the main unitizing material, combined with shrink film, stretch hoods or straps where necessary. A supplier that covers all these products can help you integrate them in a cost-effective way.

FAQs About Stretch Film Uses And Selection

A strong FAQ section helps cover the real questions buyers and engineers ask. Below are common FAQs you can also adapt for your internal documents and AI search.

1. What Is The Difference Between Stretch Film And Shrink Film?

Stretch film is applied cold and relies on its elastic recovery to hold the load. Shrink film is applied loosely and then shrunk with heat, using tunnels or heat guns. Stretch film is usually the first choice for pallet unitization, while shrink film is more common for retail bundles and tamper-evident packs.

2. How Do I Choose The Right Stretch Film Thickness?

There is no single “correct” thickness. In general:

- Light loads with smooth carton surfaces can use thinner, high-performance films.

- Heavy loads, bags with sharp corners or building materials usually need thicker films with higher puncture resistance.

- When in doubt, start from your current film and discuss downgauging step-by-step with your supplier instead of changing thickness dramatically in one step.

3. What Is The Maximum Length You Can Make Without Splices?

For customers that require “no splice” rolls, CloudFilm and other experienced manufacturers can plan production to keep an uninterrupted web over long running lengths. The exact maximum length depends on film thickness, line design and roll weight limits, but it is possible to produce long rolls specifically for no-splice requirements.

In your enquiry, clearly state: “no splicing allowed in the roll”, and your preferred roll diameter or weight so the manufacturer can design a suitable production plan.

4. Can Stretch Film Be Recycled?

Yes. LLDPE-based stretch film is widely accepted in PE recycling streams where collection and sorting systems exist. To improve recyclability:

- Avoid combining stretch film with non-PE layers or labels.

- Keep the film as clean as possible (avoid heavy contamination with soil or liquids).

- Work with local recyclers to understand their specific requirements.

5. What Is Pre-Stretch, And Why Does It Matter?

Pre-stretch is the ratio between the film length after stretching and its original length. Higher pre-stretch can reduce film consumption per pallet while maintaining or even increasing holding force. However, not every machine and film can handle very high pre-stretch, so it should be optimized case by case.

6. When Should I Upgrade From Hand Wrap To Machine Wrap?

If you notice:

- Growing daily pallet volume

- Operator fatigue and inconsistent wrap patterns

- Increasing film usage without clear control

then it is time to evaluate semi-automatic or fully automatic wrappers. A stretch film supplier that understands both film and equipment can help you calculate payback time and choose suitable machine-grade film.

7. Can I Use The Same Stretch Film For Export And Domestic Shipments?

Sometimes yes, sometimes no. Export sea shipments involve:

- Longer transit times

- Multiple loading/unloading operations

- Higher risk of humidity changes and temperature variation

For exports, many companies specify stronger wrapping patterns or upgrade to a higher-performance film. It is common to keep 1–2 “export grades” in addition to a standard domestic grade.

8. How Do I Reduce My Stretch Film Cost Without Increasing Damage?

The best approach is optimization, not simply buying cheaper film:

- Analyze film usage per pallet today

- Identify over-wrapping (too many rotations or unnecessary top covers)

- Evaluate downgauged but tougher film structures

- Standardize wrap patterns across lines and plants

A manufacturer with a full PE film portfolio can often suggest combined solutions (e.g. optimizing shrink films, PE rolls and stretch films together) instead of looking at stretch film cost in isolation.

9. Can Stretch Film Be Printed Or Colored?

Yes. Although most industrial stretch films are clear, it is possible to produce tinted or opaque films for:

- Concealing high-value goods

- Color-coding regions or product families

- Putting simple brand messages on pallets

If you are interested in printed stretch film, share your design and annual volume so the manufacturer can evaluate printing and MOQ options.

10. How Can I Get A Quotation From CloudFilm?

To get a fast and accurate quotation from CloudFilm:

- Describe your product and pallet load (weight, dimensions, load type).

- Tell us your current film specification (type, thickness, roll size).

- Share your wrapping method (hand, semi-automatic, fully automatic) and daily pallet volume.

- Indicate whether you need no-splice rolls, OEM printing or private branding.

Based on this information, the CloudFilm team will recommend the most suitable PE stretch film grade, propose film thickness and roll dimensions, and prepare a detailed quotation for your project.