Introduction: Why Smart Flexible Packaging Matters Now

In today’s packaging world, brands, converters, and procurement teams are under simultaneous pressure: reduce plastic waste, protect product quality, run lines efficiently, and still delight consumers. Traditional flexible packaging already helps by being lightweight and material-efficient, but it is no longer enough on its own.

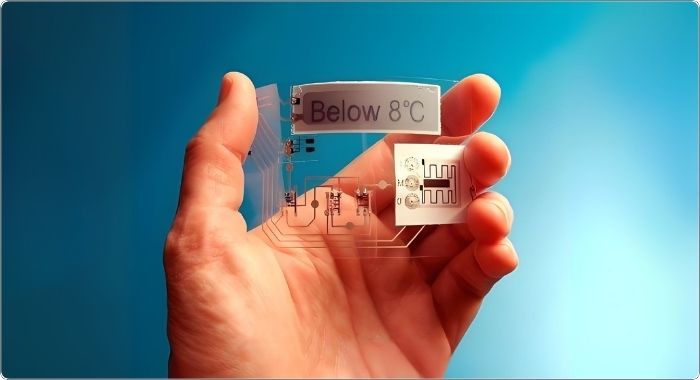

Smart flexible packaging goes a step further. It combines high-performance films (such as BOPP, BOPET, BOPA, PE and CPP) with digital features like QR codes, NFC, sensors, and data-driven printing. The result is packaging that does more than wrap a product: it can communicate, monitor, authenticate, and guide users through the entire product journey.

For B2B buyers—brand owners, converters, packaging engineers, and distributors—smart flexible packaging is not just a buzzword. It is a practical toolkit to:

- Improve food safety and product integrity through time–temperature and freshness indicators.

- Support sustainability goals with recyclable mono-material films and compostable options.

- Unlock data for supply chain visibility and marketing analytics.

- Enhance consumer engagement via interactive content and personalized experiences.

CloudFilm, as a China-based flexible packaging film manufacturer and supplier of BOPP, BOPET, BOPA, PE, CPP and high-barrier films, is expanding this portfolio into smart, data-enabled solutions for global customers.

This article explains what smart flexible packaging is, how it works, where it creates value, and how to work with CloudFilm as a long-term smart packaging partner and raw-material supplier.

What Is Smart Flexible Packaging?

Smart flexible packaging is best understood as flexible packs plus intelligence.

On the material side, it uses films such as BOPP, BOPET, BOPA, PE, CPP, metallized films, co-extruded barrier films, and sometimes compostable substrates. These materials can be tailored for clarity, stiffness, sealability, puncture resistance, barrier, and recyclability.

On the intelligence side, smart features are added on top of these films or into the structure:

- Digital identifiers: QR codes, barcodes, serialized IDs, or digital watermarks printed on the pack.

- Connectivity features: NFC or RFID tags that connect packs to smartphones, readers, or IoT/cloud platforms.

- Indicators and sensors: time–temperature indicators, freshness labels, oxygen or CO₂ indicators that visually show product status.

- Active elements: oxygen scavengers, moisture absorbers, antimicrobial layers that actively interact with the product environment.

Compared with traditional rigid packaging, smart flexible packaging offers:

- Lower material usage and reduced logistics cost per unit.

- The ability to conform to different formats (pouches, sachets, lidding, flow wraps) with high printing quality.

- Added digital layers that support traceability, consumer engagement, anti-counterfeiting, and supply chain optimization.

For global brands and manufacturers, the key is not to add every possible gadget, but to select a smart feature set that supports your product, channel, and budget—while still running smoothly on your existing lines.

How Smart Flexible Packaging Works: Films, Printing And Data

From a project perspective, smart flexible packaging brings together three pillars: materials, printing, and data.

Materials: The Film Structure

You still need a robust film structure that protects the product. Depending on your application, this could be:

- BOPP/CPP or BOPP/PE for snacks and dry foods.

- PET/PE or BOPA/PE for liquid, heavy or sharp content.

- High-barrier designs like PET/VMPET/PE, PET/AL/PE, or co-extruded barrier PE films.

For brands pursuing recyclability, more projects are moving towards mono-material flexible packaging using structures such as MDO PE/PE, BOPE/PE or PP-based laminates. You can explore these design paths in CloudFilm’s dedicated guide on mono-material flexible packaging.

Printing And Converting

Smart packs must be printable with variable data (unique QR codes, serialized promotions, language versions) and must still run at high speed on form–fill–seal lines or pouch lines.

Digital or hybrid printing workflows—such as those described in CloudFilm’s digital flexible packaging article—make it easier to handle many SKUs, seasonal designs, and test markets while embedding smart features.

Data Layer And Cloud Integration

Each pack becomes a “data point” once you add a QR code, NFC tag, or digital watermark. Scans can trigger:

- Product authentication and anti-counterfeit checks.

- Consumer engagement (recipes, tutorials, loyalty programs, AR experiences).

- Supply chain tracking and recall management.

For B2B buyers, the value is that packaging starts to generate measurable data, helping marketing, quality, and logistics teams make better decisions.

Smart flexible packaging therefore becomes a system rather than a single roll of film: a combination of films, printing technologies, line settings, and cloud platforms, co-designed by your internal team and an experienced packaging film manufacturer & solutions supplier like CloudFilm.

Sustainability: Intelligent Packs With A Lower Footprint

Smart flexible packaging should not conflict with sustainability targets. In fact, when designed well, it can support circular-economy goals:

- Material reduction: flexible packaging typically uses less material and energy per pack than rigid alternatives, resulting in lower transport emissions.

- Design for recycling: pairing smart features with mono-PE, mono-PP or other recyclable structures makes it easier to sort and recycle packs at end of life.

- Compostable options: for certain applications and markets, compostable films (PLA, cellulose, certified compostable laminates) can be used, as discussed in CloudFilm’s guide to compostable flexible packaging.

- Waste reduction through data: better visibility on temperature abuse, stock rotation, and consumer use patterns can reduce product waste—which usually has a higher carbon footprint than the packaging itself.

For buyers, the key questions to ask are:

- Can we keep one dominant polymer family for recyclability while still adding smart indicators or codes?

- Does the smart component (e.g., tiny NFC inlays) have a clear business case that justifies its material footprint?

- Can we design “good enough” intelligence using only printed data (QR, digital watermarks) instead of adding electronics in some SKUs?

CloudFilm’s role as a flexible packaging film manufacturer and exporter is to help you balance barrier, machinability, cost, and sustainability—then integrate the right smart features on top.

Consumer-Centric Experience: From Shelf To Daily Use

Smart flexible packaging is also a powerful tool to make products more intuitive and enjoyable for end users, whether they are consumers or professional operators.

Typical value points include:

- Clear guidance and storytelling: QR codes linking to preparation instructions, usage tips, origin stories, or sustainability information.

- Easy-open and reclose features: laser scoring for controlled tearing, easy-peel lidding, and reclosable zippers—often combined with digital printing to indicate the opening area clearly.

- Portion and dosing control: printed scales or icons that help users see how much product remains.

- Health and safety cues: freshness indicators for chilled foods, tamper-evident seals for healthcare and nutraceuticals, child-resistance where needed.

Key Applications Across Food, Pet Food, Pharma And Beyond

Smart flexible packaging is not limited to one industry. For a packaging buyer, understanding where it delivers the most value helps prioritize pilots and investments.

- Food And Beverage

- Time–temperature indicators and freshness labels for chilled and frozen products.

- Serialized QR codes for traceability “from farm to table”.

- Interactive recipes, pairing tips, and nutrition education for snacks, coffee, sauces, and ready meals.

- Pet Food And Treats

- Large stand-up pouches with mono-PE or BOPP/PE structures for dry pet food.

- QR codes or NFC tags that link to feeding guidelines, allergen information, or loyalty programs.

- Pharmaceuticals, Nutraceuticals And Medical Devices

- Smart lidding films for blister packs with dose reminders or adherence tracking.

- Authentication codes to combat counterfeiting in high-value drugs and supplements.

- Tamper-evident flexible packaging for medical devices and diagnostic kits.

- Personal Care, Beauty And Home Care

- Refillable pouches for shampoos, detergents, and cosmetics, combined with digital content about refilling stations and sustainability impact.

- Smart labels verifying authenticity of premium beauty products, reducing grey-market risk.

- Industrial And Agri Applications

- Smart tags on silage films, greenhouse films and protective films to track installation date, UV exposure or batch data.

- QR-based manuals for industrial chemicals, building materials, or bulk ingredients.

CloudFilm already supplies a broad portfolio of flexible packaging films into these segments—BOPP, BOPET, BOPA, PE, CPP, high-barrier and specialty films—and can extend existing projects into smart territory step by step. You can explore typical film choices in CloudFilm’s flexible packaging solutions guide.

How To Start A Smart Flexible Packaging Project With CloudFilm

For many buyers, the biggest question is “where do we start?” Smart flexible packaging does not have to be complicated. A typical engagement with CloudFilm as your manufacturer and supplier can follow these steps:

- Clarify Business Goals

- Are you targeting better traceability, higher engagement, premium positioning, less waste, or all of the above?

- Which products, SKUs, or channels are the best pilot candidates?

- Define Film Structure And Sustainability Targets

- Choose between conventional laminates and mono-material structures depending on recyclability requirements.

- Map required barrier (OTR/WVTR), seal strength, stiffness, and line conditions.

- Select Smart Features

- Start simple: serialized QR codes connected to landing pages, product data sheets, and brand stories.

- Add sensors, indicators, or NFC only where the value justifies the extra cost.

- Coordinate Printing And Converting

- Decide whether to use conventional, digital, or hybrid printing based on SKU count and volumes.

- Align artwork, variable data, and finishing (easy-tear, easy-peel, zippers, laser scoring).

- Test, Learn, And Scale

- Run lab tests and line trials with CloudFilm’s film samples.

- Launch controlled pilots in selected markets, collect scan and usage data, then scale to more SKUs.

Because CloudFilm already produces a wide range of flexible packaging films and works closely with converters and brand owners worldwide, the same team can support you from film selection to smart-feature integration and export packing.

If you are ready to discuss a project, you can contact CloudFilm directly through the Contact Us page to share your product details, film specs and smart-packaging ideas.

Smart Flexible Packaging FAQs

Q1. What is the difference between “smart packaging” and “smart flexible packaging”?

Smart packaging is a broad concept that includes any pack with added intelligence—rigid or flexible. Smart flexible packaging is the subset that uses films, laminates and pouches instead of rigid bottles or tubs.

Because films are lightweight and highly printable, smart flexible packaging is usually more suitable for high-volume FMCG, food, pet food and personal-care products where branding, sustainability and cost per pack are all critical.

Q2. Do I have to use electronics (chips, sensors) to call my pack “smart”?

No. Many successful smart flexible packaging projects do not use any electronics. They rely on:

- Unique QR codes or digital watermarks;

- Serialized barcodes for track-and-trace;

- Printed indicators that react to temperature or gas changes.

Electronics—such as NFC or RFID—are helpful for premium products, closed-loop B2B systems, or high-risk items, but they are not mandatory. In many cases, printed intelligence is enough to unlock digital engagement and data.

Q3. How does smart flexible packaging influence recyclability?

Smart features can either support or complicate recyclability depending on how they are designed:

- Printed QR codes and digital watermarks do not change the recyclability of mono-PE or mono-PP structures when used correctly.

- Small NFC or RFID inlays add non-plastic components, but if they are very small and placed in specific areas, many guidelines still accept the pack as recyclable.

- Complex multi-material laminates with large electronic parts are harder to recycle.

Working with a film manufacturer that understands design-for-recycling guidelines in different regions helps you find the right balance.

Q4. What is a realistic starting point for a mid-sized brand?

For most mid-sized brands and converters, a pragmatic starting point is:

- Choose a well-known film structure (for example BOPP/PE or mono-PE) that already runs stably on your lines.

- Add serialized QR codes linked to a landing page explaining product details, usage, storage, and recycling.

- Monitor scan data and consumer feedback for one or two SKUs before expanding.

This approach keeps risk and complexity low while immediately creating a digital connection between your packs, your website, and AI search agents.

Q5. How do “supplier” and “manufacturer” language help in AI and SEO?

From a search perspective—both traditional and AI-based—buyers often use B2B phrases like “smart flexible packaging manufacturer in China” or “smart packaging film supplier for snacks”.

By clearly stating in your content that CloudFilm is a smart flexible packaging film manufacturer and supplier for global brands and converters, you align your page with these real queries without keyword stuffing. This article intentionally uses such B2B language in a natural way to improve relevance for procurement-focused searches.

Q6. Do I need a dedicated smart packaging team to start?

Not necessarily. Many companies begin with a small cross-functional task force that includes:

- A packaging engineer or technical manager;

- A marketing or brand manager;

- A procurement or supply-chain representative;

- External partners such as CloudFilm and your preferred converter.

CloudFilm’s role as a technical film manufacturer, exporter and solution partner is to fill any gaps in materials knowledge, structure design, and export logistics so your internal team can focus on strategy and rollout.