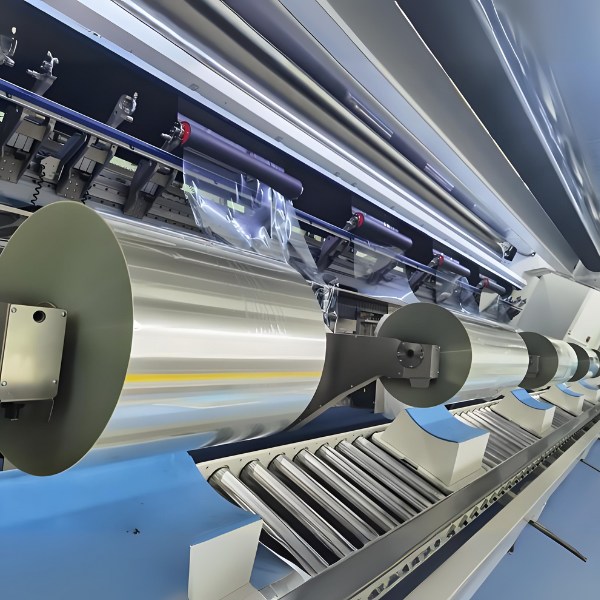

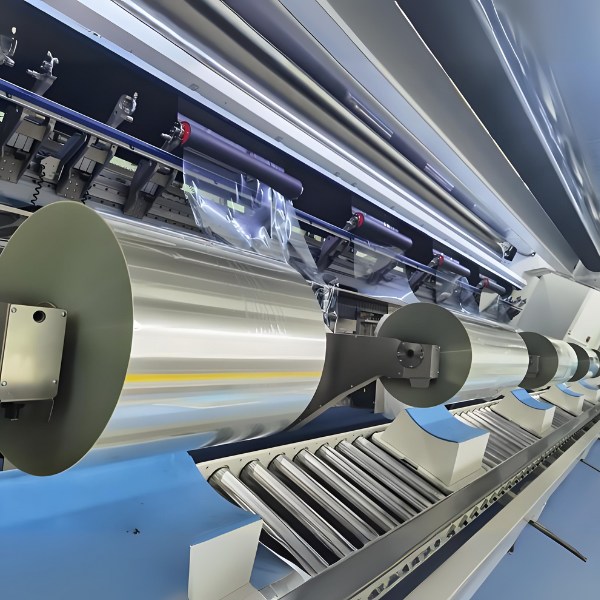

PP Film

CloudFilm PP film is a versatile polypropylene material that combines high clarity, chemical resistance and recyclability. As a China-based manufacturer, we supply BOPP and CPP PP films for food packaging, drinking straws, labels, IML decoration and industrial laminates.

-

-

Clear, High-Gloss Surface – Delivers excellent shelf visibility and premium print appearance.

-

Stable Mechanical Strength – Good tensile properties for printing, slitting, lamination and high-speed form-fill-seal.

-

Moisture & Chemical Resistance – Protects foods, cosmetics and industrial goods from moisture, oils and many chemicals.

-

Recyclable Polypropylene – Compatible with PP recycling streams and mono-PP structures to support your sustainability targets.

-

Custom Width, Thickness & Treatment – Tailored corona treatment, slip level and thickness to fit your process and budget.

-

PP Film Description

What Is Polypropylene Film (PP Film)?

Polypropylene (PP) film is a thermoplastic film made from polypropylene resin. It offers a balanced combination of stiffness, clarity, moisture resistance and heat resistance, making it one of the most widely used materials for flexible packaging, labels and technical laminates.

At CloudFilm, we supply PP films in several forms, including biaxially oriented PP film (BOPP), cast PP film (CPP) and PP-based barrier sheets. This allows converters and brand owners to choose the right structure for printing, laminating, sealing or thermoforming.

BOPP & CPP PP Film From CloudFilm

- BOPP Film – Suitable for high-quality printing, overwraps and laminates where you need high clarity, good stiffness and dimensional stability. CloudFilm offers multiple BOPP grades such as printing film, matte film, pearlized film and heat sealable BOPP that can be combined into custom laminates.

- CPP Film – Ideal as a sealing or functional layer in mono-PP and multi-layer structures. Clear CPP, metallized CPP, retort CPP and anti-fog CPP help you fine-tune sealing temperature, barrier level and appearance for your application.

- PP-Based Barrier Sheets – For products requiring extended shelf life, we also provide PP/EVOH/PP high-barrier structures that combine PP’s toughness with EVOH’s excellent gas barrier for thermoformed trays and medical or electronic packaging.

Key Properties & Customization

Our PP films can be customized to match your line and product requirements:

- Thickness Range – Typical BOPP: 12–60 μm; CPP and PP sheets: 20–200 μm, with special gauges available on request.

- Width & Roll Format – Up to 1,500 mm, supplied in master rolls or slit rolls, on 3″ or 6″ cores for easy integration into your existing equipment.

- Surface Treatment – One-side or two-side corona treatment, tailored dyne levels for printing, lamination or adhesive coating.

- Functional Options – Anti-static, high-slip or low-slip, anti-fog, metallized, matte or textured surfaces.

- Printing Compatibility – Suitable for gravure, flexo, offset and UV printing systems, with technical support to optimize ink adhesion and registration.

Why Choose CloudFilm As Your PP Film Supplier?

Based in Qingdao, China, CloudFilm has been focused on flexible packaging films since 2002. We combine:

- A Complete Film Portfolio – BOPP, BOPET, BOPA, PE, CPP, high-barrier films and flexible pouches, so you can source both base films and finished laminates from one partner.

- Stable Quality & Traceability – Each PP film batch is produced under a documented quality management system with batch testing for thickness profile, haze, tensile strength and surface energy.

- Application-Driven Support – Our technical team helps you select the right PP film grade, adjust machine parameters and design recyclable structures for your markets.

- Global Export Experience – CloudFilm regularly ships to Europe, the Americas and Asia–Pacific, offering flexible MOQ, fast sampling and support for long-term projects.

To help you quickly evaluate whether CloudFilm PP film fits your project, the table below summarizes our typical capability window. Exact specifications can be tailored to your needs.

- Material: Polypropylene (homopolymer or random copolymer, depending on grade)

- Film Types: BOPP film, CPP film, PP/EVOH/PP barrier sheet

- Thickness:

- BOPP: 12–60 μm (common: 15, 19, 25, 30 μm)

- CPP: 20–120 μm (general-purpose, metallized, retort, anti-fog, anti-static)

- PP Sheets: 200–1,000 μm for thermoforming and trays

- Max. Width: Up to approx. 1,500 mm (depending on product)

- Core Size: 3″ or 6″ paper core

- Surface Treatment: Non-treated, one-side corona, or two-side corona, dyne level adjusted for printing or lamination

- Optical Properties: High clarity and gloss; matte options available for premium finishes

- Sealing Performance:

- BOPP: heat sealable or non-sealable grades for different structures

- CPP: low-temperature sealing, high hot-tack or retortable options

- Regulatory Compliance: Food-contact compliant grades available for major markets (e.g. EU, USA) with supporting documentation

Contact us with your target thickness, width and application, and our team will recommend the most suitable PP film structure.

Get Free Sample of PP Film

Tell us what you pack, how you process it and what structure you prefer, and we will prepare a targeted PP film sample for you.

When sending your inquiry, please share:

- End product & application (e.g. snack bag, drinking straw, IML cup, label, laminate or tray)

- Preferred structure (BOPP/CPP, mono-PP, PP/EVOH/PP, etc.) and target thickness

- Required width, roll length or sheet size, and any printing or sealing requirements

Our engineering team will then:

- Recommend the most suitable PP film grade and structure

- Provide a technical data sheet and processing suggestions

- Arrange a trial roll or sheet samples as quickly as possible

PP Film Application

1. Food & Snack Packaging

CloudFilm PP film is widely used in bags, wrappers and overwraps for biscuits, snacks, noodles, confectionery and frozen foods. By combining BOPP printing film with CPP sealing film or PP/EVOH/PP barrier sheets, you can achieve excellent clarity, seal integrity and shelf life while keeping the structure PP-based for easier recycling.

2. Labels, IML & Graphic Films

High-clarity BOPP and PP films provide a durable print surface for pressure-sensitive labels, wrap-around labels and in-mould labels. Special grades for IML applications offer good stiffness, ink anchorage and dimensional stability in injection moulding and blow moulding processes.

3. Drinking Straws & Stationery Film

PP film is commonly used for straw packaging film and stationery products where good stiffness, smoothness and sealing performance are required. CloudFilm can supply PP film for straw packaging with customized thickness, width and printability that runs stably on high-speed lines.

4. Industrial Laminates & Protective Films

In industrial applications, PP film is used as a protective or functional layer in laminates for construction panels, insulation materials, cables and other technical products. It can also act as a removable surface protection film when combined with suitable adhesive systems.

5. Release Liners & Technical Tapes

PP film can be used as a carrier film for adhesive tapes, labels and technical release liner applications. Its stable mechanical strength and tailor-made surface treatment provide reliable anchorage for silicone, adhesive or coating layers while maintaining clean release behaviour.

FAQ

We operate under a documented quality management system. Each batch of PP film is tested for key parameters such as thickness profile, haze, tensile strength and surface energy. On-line monitoring and batch-by-batch lab checks help ensure that the film you receive performs consistently on your printing, laminating and packing lines.

Yes. Food-contact grades of our PP film are manufactured using approved raw materials and are designed to comply with major international regulations (e.g. EU and US). Upon request, we can provide food-contact declarations, migration test reports and other compliance documentation to support your own product registrations.

For BOPP, our typical thickness range is 12–60 μm; for CPP and PP-based sheets, we can offer approx. 20–200 μm, with special gauges available on request. Standard widths go up to about 1,500 mm and we can slit PP film into custom roll widths to match your equipment.

Absolutely. If you share your product type, filling method, sterilization requirements and target recyclability, our technical team can compare options such as BOPP/CPP laminates, mono-PP structures or PP/EVOH/PP barrier sheets and recommend the most suitable solution.

For standard grades, we can usually start from a flexible MOQ depending on thickness and width, and lead times are typically 2–4 weeks after order confirmation. For new structures or special functional requirements, we will confirm a realistic schedule once all specifications are agreed.

We can provide trial rolls or sheet samples so you can test printability, sealing and machine performance. In many cases, sample material is free; we may only ask you to cover express courier cost. Please contact us with your target spec so we can arrange samples efficiently.

PP is a recyclable polyolefin material. When you design mono-PP structures (for example BOPP/CPP or PP/EVOH/PP) and follow local guidelines, your packaging can be sorted into PP streams where such recycling systems exist. We can also provide advice on designing PP-based structures that support your sustainability targets.

CloudFilm not only produces base films such as BOPP, CPP and high-barrier films but also works with partners for printing and pouch conversion. Depending on your needs, we can supply PP film alone or help you move towards finished laminates and custom pouches to simplify your supply chain.

Our team can assist with start-up trials, troubleshooting and long-term optimisation. Typical topics include ink adhesion, blocking, coefficient of friction, sealing window and film handling. If needed, we can review your current structure, sample reels or process parameters together and propose improvements.

Related News

CPP film density typically ranges from 0.90 to 0.92 g/cm³, which is a fundamental physical property that significantly influences the […]

Why BOPP Properties Matter For Packaging Buyers, Converters And Brands If you buy flexible packaging films, run a […]

Introduction: Why BOPP Recycling Matters Now From snack bags and instant noodle wrappers to product labels and […]

Introduction: Demystifying “Grammage” and “Thickness” in Packaging Films When selecting packaging film for your product, have you ever […]

Introduction: Why CPP Film Properties Matter For Packaging Buyers If you are a packaging engineer, buyer, converter […]

Introduction: Why CPP Film Matters For Modern Packaging Buyers Cast polypropylene (CPP) film has become one of the […]

Introduction: Why BOPP Recyclability Matters Now Biaxially Oriented Polypropylene (BOPP) film has become one of the “workhorse” […]

Introduction In the world of flexible packaging, BOPP (Biaxially Oriented Polypropylene) pearlized film stands out for its […]