PET/PE Film Structures & Quick Selection Guide

Choosing the right PET/PE structure depends on your product, pack format and shelf-life target. Use the guide below as a starting point when talking with CloudFilm.

- Standard PET/PE – Dry Food, Coffee & Snacks

Typical total thickness: 40–80 μm

For pouches and small bags of coffee, tea, nuts and snacks where good print quality and basic barrier are required.

- Reinforced PET/PE – Frozen Food & Liquids

Typical total thickness: 70–120 μm

Designed for heavier contents, frozen foods and liquid products that need stronger puncture resistance and seals. Often used on high-speed FFS lines.

- High-Barrier Laminates – Extended Shelf Life

For products requiring longer shelf life or stricter oxygen limits, PET/PE can be combined with metallized layers (PET/VMPET/PE) or barrier nylons (PA/PE film) to reach higher barrier levels.

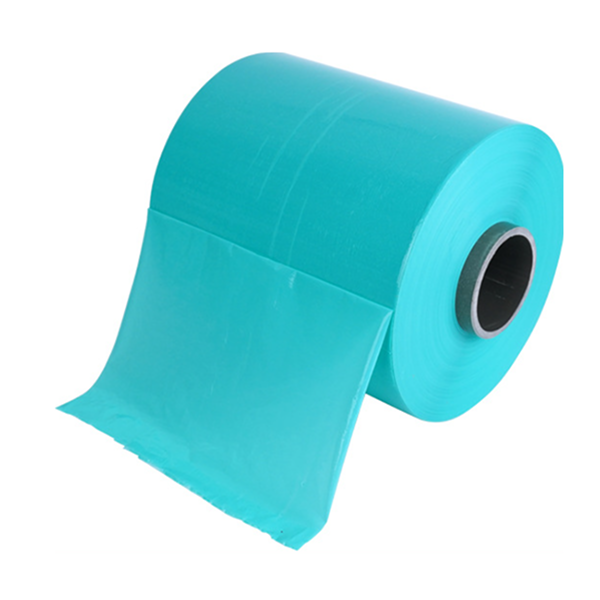

- Special Structures – Medical & Industrial Projects

For medical devices, diagnostic kits or industrial parts, CloudFilm can design special PET/PE structures and combine them with materials from our BOPET film and speciality film ranges, so you can balance performance, cost and regulations.

If you are not sure which structure fits your product, simply share your application, process and shelf-life target with us. CloudFilm will suggest a suitable PET/PE film and provide trial samples.