PET Foil Laminate

CloudFilm’s PET foil laminate combines PET film with aluminum foil and heat-seal layers such as PE or CPP to create a high-barrier, multi-layer structure. It is ideal for coffee and snack bags, pharmaceutical blister packs, industrial insulation and EMI shielding applications.

- High Barrier Against Moisture, Oxygen And Light: The PET/AL laminate effectively blocks water vapor, oxygen and UV light, helping coffee, snacks and sensitive powders maintain flavor, aroma and active ingredients over a long shelf life.

- Strong Yet Flexible Structure For Converting: Compared with pure foil, the PET layer improves tear and puncture resistance and reduces wrinkling, making the laminate more stable on high-speed printing and lamination lines.

- Heat Sealable To PE Or CPP For Many Formats: CloudFilm can design PET/AL/PE or PET/AL/CPP structures that seal reliably on horizontal and vertical FFS packaging lines, as well as for pre-made bags and Roll Stock.

- Halogen-Free, RoHS-Compliant And Recyclable PET Layer: The PET side is halogen-free and free from plasticizers, formaldehyde and heavy metals, helping brand owners meet food and electronics regulations while moving toward more sustainable packaging.

PET Foil Laminate Description

What is PET Foil Laminate?

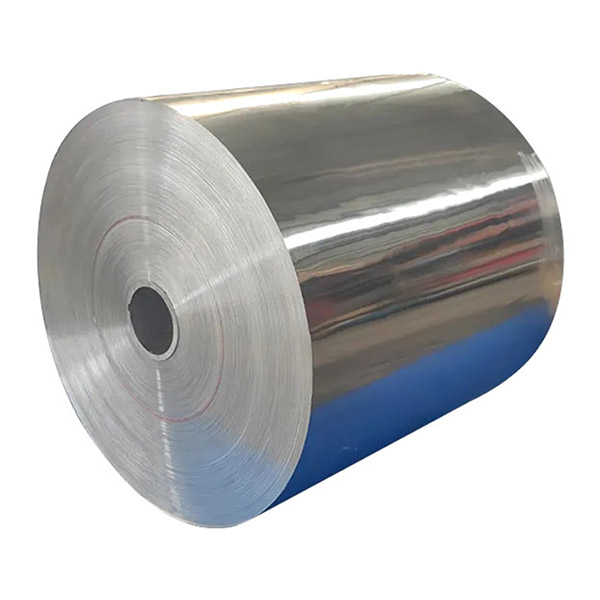

PET foil laminate is a multi-layer flexible packaging material made by laminating a strong PET film to a thin aluminum foil and, in many cases, to a heat-seal layer such as PE or CPP.

In this structure, the PET layer provides printability, mechanical strength and scuff resistance, while the aluminum foil delivers an almost complete barrier to oxygen, moisture and light. The sealant layer allows the laminate to be converted into roll stock or pre-made pouches for food, pharmaceutical, industrial and electronics applications.

Typical Structures & Specifications

- Common structures: PET/AL/PE, PET/AL/CPP, PET/AL/PET/LDPE

- Total thickness: typically 60–150 µm (can be customized based on barrier level and stiffness requirements)

- Roll width: usually 200–1,300 mm depending on your packaging line and application

- Roll OD and core: customized according to your Roll Stock requirements

- Surface: glossy or matte PET surface, corona-treated for high-quality printing and downstream lamination

Why Choose CloudFilm As Your PET Foil Laminate Partner?

CloudFilm is more than a trader – we manufacture key flexible packaging films in-house, including BOPET, BOPP, PE and CPP, and cooperate closely with aluminum foil suppliers. By combining our film production with lamination and pouch-making capabilities, we can deliver PET foil laminates that are truly matched to your products and processes.

Whether you need PET/AL/PE for coffee bags, PET/AL/CPP for retortable structures or PET/AL laminates for industrial insulation and EMI shielding, our technical team will help you choose the right structure and recommend compatible solutions such as Flexible Packaging Aluminum Foil, Retort Pouches or other High Barrier Films.

Get Free Sample of PET Foil Laminate

Ready to test PET foil laminate on your line?

Share your target structure (for example PET/AL/PE or PET/AL/CPP), thickness, roll width and application (coffee bags, pharma blister, insulation, electronics, etc.), and our team will recommend a suitable specification and send you a quotation and sample plan.

CloudFilm can ship trial rolls or pre-made pouches to your destination by air or sea, depending on your schedule and volume. Contact us now to discuss your project with a packaging engineer.

PET Foil Laminate Applications

Food Packaging

PET foil laminate is widely used for coffee, powdered beverages, nuts, dried fruits and high-value snacks that need long-term protection. Typical structures such as PET/AL/PE provide strong aroma and oxygen barrier, and can be supplied as printed Roll Stock or pre-made bags.

Pharmaceutical Packaging

In pharma applications, PET foil laminate helps create blisters and sachets that protect tablets, capsules and sensitive powders from moisture and light. Our materials can be designed to meet relevant food-contact and pharma-grade requirements and to work with your existing forming or sealing equipment.

Industrial Insulation

PET/AL laminates are also used as reflective insulation layers in building materials, HVAC systems and automotive heat shields. The aluminum foil reflects radiant heat, while the PET layer provides strength and dimensional stability during installation and use.

Electronics Shielding

For cables, flexible circuits and electronic components, PET foil laminate offers both EMI shielding and mechanical protection. CloudFilm can customize thickness, slit width and winding direction to fit your cable wrapping or electronic insulation process.

FAQ

PET foil laminate is a multi-layer structure where a PET film is laminated to aluminum foil and a sealant such as PE or CPP. PET provides strength and printability, while the foil gives very high barrier to moisture, oxygen and light. Together they help maintain flavor, aroma, potency and shelf life.

Common structures include PET/AL/PE, PET/AL/CPP and PET/AL/PET/LDPE. For coffee and snacks we often recommend PET/AL/PE, while for retortable applications we may design PET/AL/CPP or combine PET foil laminate with our Retort Pouches.

As a guideline, total thickness is usually between 60 and 150 µm, but we can adjust it based on your barrier and stiffness requirements. Standard roll widths are 200–1,300 mm, and we can slit to your exact film and Roll Stock.

Yes. We can supply PET foil laminate as printed or unprinted roll stock for FFS lines, and we can also convert it into pre-made pouches such as flat bags, gusseted bags and stand-up pouches through our Flexible Pouches portfolio.

Some PET foil laminate structures can be designed for retort conditions, but this must be evaluated carefully based on your product, temperature and time. For 121°C sterilization we usually recommend combining PET foil laminate with retortable CPP grades or using dedicated Retort Pouches ).

For standard structures, our typical MOQ starts from around 300–500 kg per structure or design, depending on printing and lamination requirements. Lead time is usually 15–25 days after artwork and order confirmation. For trial orders we can often arrange smaller quantities – please contact us to discuss your project.

Yes. On request we can share typical OTR/WVTR data for our PET foil laminate structures and provide compliance documents (such as FDA or EU food-contact statements) for relevant materials. For special projects, additional testing can be arranged through our partner laboratories.

Related News

BOPET film is one of the most important polyester films used in modern flexible packaging. It combines high strength, […]

In many industries, packaging is no longer “just a bag” or “just a film.” It is a silent […]

Why PET ALOx Matters For Modern Packaging In food, pharmaceutical and technical packaging, buyers are under pressure to […]

Introduction to Metallized Films Aluminum-coated films, also known as metallized films, are versatile materials created by depositing […]

High barrier films play a pivotal role in safeguarding products against the detrimental effects of moisture and oxygen. These […]