Why Choose CloudFilm for LDPE Film

• Proven PE Film Expertise Since 2002: CloudFilm has specialized in flexible packaging films for over two decades, with a complete PE film portfolio covering LDPE, LLDPE, HDPE, MDOPE, CPE and related structures.

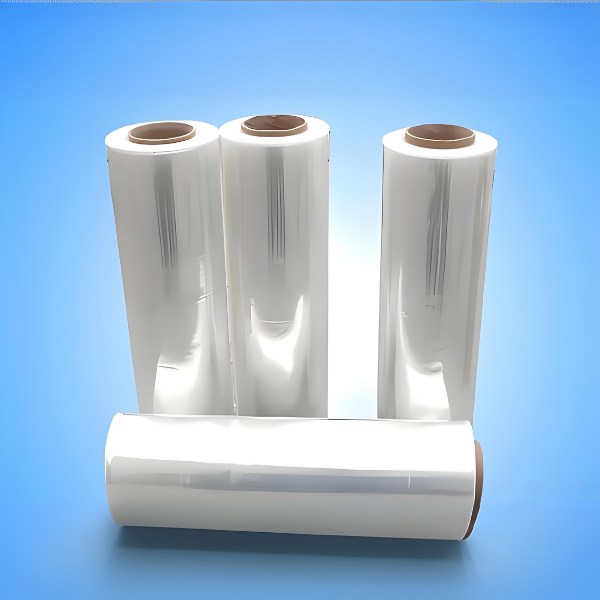

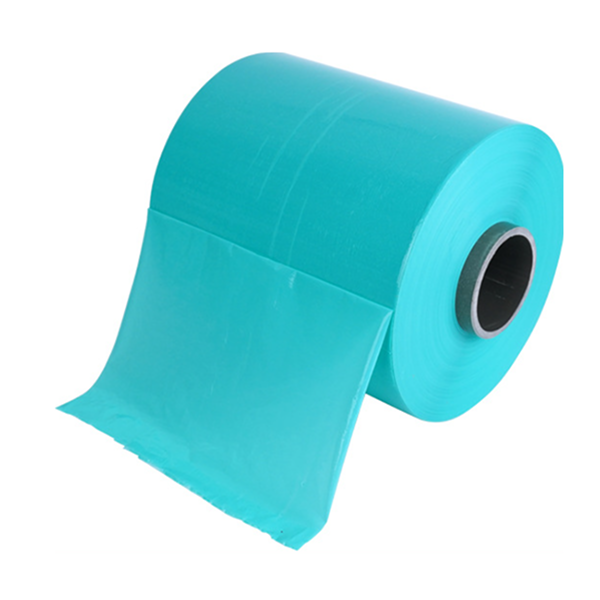

• One-Stop PE Packaging Solutions: Besides LDPE film, we also supply PE roll, PE stretch film, PE shrink film and custom PE pouches, helping you build a consistent packaging system across bags, liners, wrap and outer packs.

• Engineering Support, Not Just Film Rolls: Our technical team can review your current film, suggest equivalent LDPE grades or alternative PE structures, and support trials on your existing equipment to reduce risk.

• Focus on Recyclable & Mono-Material Designs: CloudFilm actively develops mono-material PE solutions, combining LDPE with MDO PE, BOPE and recyclable pouches to help you meet regulatory and brand sustainability targets.

• Export Experience & Stable Supply: With long-term export experience and strict quality management, we support customers in Europe, Oceania, Asia and the Americas with consistent quality and on-time delivery.