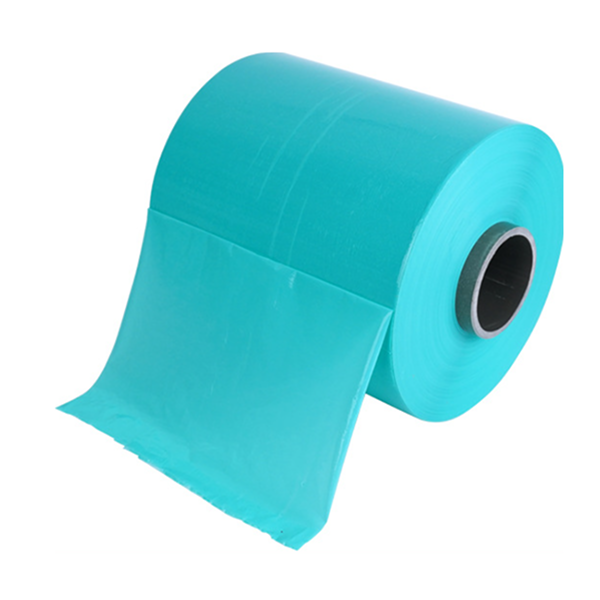

HDPE Film

CloudFilm HDPE film is a high-density polyethylene film engineered for heavy-duty packaging, agricultural covers, construction geomembranes and industrial protection. It combines high tensile strength, excellent moisture barrier and strong chemical resistance in a lightweight, cost-efficient material.

- ✔️ High Strength & Durability: Resists tearing and impact in heavy-duty bags, liners and geomembranes.

- ✔️ Superior Moisture Resistance: Very low water vapor transmission keeps products dry and protected.

- ✔️ Excellent Chemical Stability: Withstands many acids, alkalis and solvents used in industry.

- ✔️ Lightweight & Cost-Effective: High strength-to-weight ratio helps reduce material and transport costs.

HDPE Film Description

HDPE film, or High-Density Polyethylene film, is a stiff, high-strength plastic film with a typical density of around 0.94–0.96 g/cm³. It is designed for applications where you need a strong, low-permeability material rather than a soft, highly transparent film.

At CloudFilm, HDPE film is part of our complete PE film portfolio alongside LDPE and LLDPE solutions. This allows us to recommend the right density and structure for each project instead of a one-size-fits-all material.

For example, HDPE film is often used for:

- Heavy-duty bags and liners that must carry high loads

- Agricultural covers and mulch films that need strong puncture resistance

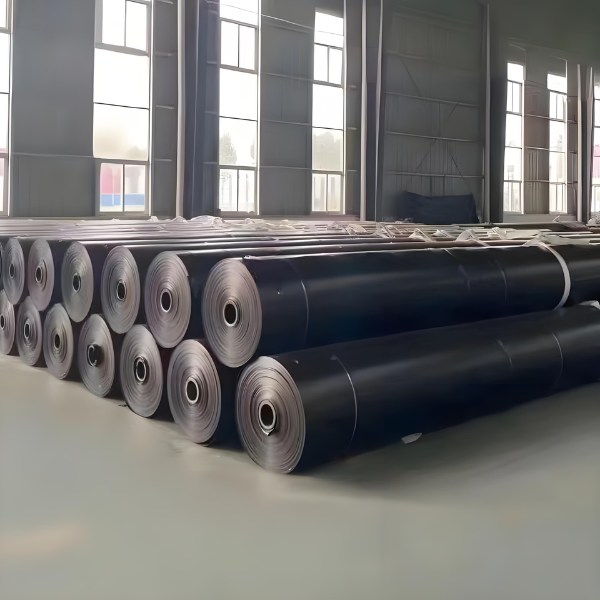

- Construction geomembranes and vapor barriers

- Industrial protection, garbage bags and biogas pool liners

CloudFilm can customize your HDPE film by thickness, width, color and additives (e.g. UV stabilizer, slip/anti-block, anti-static). If your project requires higher barrier or vacuum performance, we can also combine PE with PA or EVOH structures through films like PE PA PE Film or PE-based laminates such as PET/PE Film.

Working with CloudFilm means you get more than a film roll. Our technical team can help you choose the right HDPE grade, design the film structure and run trials on your existing equipment to reduce risk and speed up commercialization.

When you source HDPE film from CloudFilm, you can tailor the material to your exact process and application:

Thickness: Typically 20–200 μm depending on bag strength, barrier and handling needs (similar ranges to our PE Roll solutions).

- Roll Width: Commonly 300–3000 mm to match blown-film and conversion equipment.

- Colors: Natural/transparent, milky white, black or custom colors on request.

- Surface Treatment: One-side or two-side corona treatment to support printing and lamination.

- Additives: UV stabilizer, slip/anti-block, anti-static, anti-fog and other functional masterbatches.

- Supply Form: Standard rolls for converters, jumbo rolls for slitting/printing, or small rolls for end users.

If you are not sure which HDPE specification is right for your project, you can also review our broader PE Film category and talk with our team about combining HDPE with LDPE, LLDPE or PA/PE structures.

Get Free Sample of HDPE Film

Are you facing challenges with moisture, chemicals or product protection? Our high-performance HDPE film is engineered to solve these problems, offering you reliable strength and cost savings in demanding environments.

When you submit an inquiry, it is very helpful if you can share:

- End application (e.g. garbage bags, construction geomembrane, agricultural covers, industrial liners)

- Target thickness and roll width

- Color and required additives (UV, anti-static, slip/anti-block, etc.)

- Whether the film will be printed or laminated or PE Pouches.

- Estimated annual or monthly volume

The more details you provide, the faster the CloudFilm team can recommend the right HDPE specification, prepare samples and support your trials. Let us help you secure a stable, long-term HDPE film supply.

HDPE Film Applications

- Food & Dry Goods Packaging

HDPE film offers a superior moisture barrier for dry foods, grains, powders and bulk ingredients. It is often used as liners or outer bags, and can also work together with laminates such as PET/PE Film for more demanding shelf-life requirements. - Agricultural Covering Films

As greenhouse film, mulch film or silage covers, HDPE provides strong puncture resistance and low water permeability, helping farmers control temperature, suppress weeds and protect silage quality. For softer or more transparent agricultural films, you can also refer to our LDPE Film. - Construction & Geomembranes

HDPE is widely used as pond liners, canal liners, basement vapor barriers and other geomembrane applications. Its stiffness and chemical resistance make it ideal where long-term water and chemical exposure is expected. - Protective Packaging & Pallet Wrapping

HDPE film can be used for heavy-duty protective wraps and liners. For stretch wrapping and pallet stability, CloudFilm also offers dedicated PE Stretch Film solutions. - Medical & Sanitary Products

With its chemical stability and clean surface, HDPE film is used in certain sterile packaging, disposable protective products and medical waste bags. Where higher oxygen or aroma barrier is needed, we can upgrade to PA/PE or PE PA PE structures.

FAQ

HDPE film is a plastic film made from High-Density Polyethylene. It is known for its high strength, low water vapor transmission and good chemical resistance, making it ideal for heavy-duty bags, geomembranes, agricultural covers and industrial protection.

The main difference is density and resulting properties. LDPE film is softer, more flexible and usually more transparent, while HDPE film is stiffer, stronger and offers a better moisture barrier. For flexible bags and stretch wrap, LDPE is often preferred. For heavy-duty liners, geomembranes and garbage bags, HDPE is usually the better choice.

Most HDPE film is produced by blown film extrusion. HDPE resin pellets are melted and extruded through a circular die, inflated into a bubble, cooled and then flattened into film. CloudFilm operates modern blown film lines dedicated to PE films, enabling consistent quality and customizable specifications.

As a general guideline, CloudFilm typically supplies HDPE film from 20–200 μm in thickness, with roll widths from around 300–3000 mm, similar to our PE Roll range. We can adjust these ranges according to your project and equipment.

Yes, HDPE film is recyclable where collection and recycling systems exist. It is usually classified under resin identification code “2” (HDPE). Many customers use HDPE film as part of mono-material PE packaging structures together with solutions like MDO PE Film or BOPE Film to support recycling initiatives.

HDPE is widely used for food-contact applications such as dry-food liners, grain bags and certain liquid or semi-liquid packs when combined with suitable laminates. CloudFilm can supply food-grade HDPE film that meets relevant regulations; please share your target market and standards (e.g. EU, FDA) so we can confirm compliance.

To get a fast and accurate proposal, it is helpful to provide: end application, requested thickness and width, color, required additives (e.g. UV, anti-static), whether printing/lamination is needed, and estimated volume. If you are not sure, simply describe your product and we can recommend HDPE film or alternative PE solutions such as LDPE Film or PE PA PE Film

If you need stiffness, high strength and low moisture permeability, HDPE film is often the right starting point. If you need more softness, clarity and stretch, LDPE or LLDPE films may be better. For projects focused on recyclable flexible packaging, you can also review our MDO PE Film and Recyclable Pouches pages to see how different PE films work together in mono-material structures.

Related Products

Related News

In the world of modern packaging, printing, and industrial applications, the term PE laminated is a cornerstone of material science. It […]

Introduction: Why is Understanding Plastic Film Types So Crucial? Imagine you’re designing a food package that requires long-lasting […]

Introduction In today’s competitive market, custom flexible packaging has become a cornerstone of branding, logistics, and sustainability. Whether you’re a […]

Introduction: The Science Behind Packaging In our daily lives, we encounter a vast array of packages. From snack […]

In today’s flexible packaging field, MDO PE (Machine Direction Orientation) and BOPE (Biaxially Oriented Polyethylene Film) are like two […]

Introduction Polyethylene (PE) films are a cornerstone of modern packaging and manufacturing industries. With their diverse properties and […]

As brands, converters, and retailers rethink their packaging strategies, one core question keeps coming up: how do we move […]

Since the early 20th century, the versatile polyethylene (PE) films, synthesized from ethylene monomers, have marked significant breakthroughs in […]