How to Choose BOPP Thermal Lamination Film – Comparison & Ordering Checklist

Key selection points

- Substrate type– coated art paper, uncoated paperboard, digital prints or flexible films may require different EVA coat weights and adhesion levels.

- Printing process – offset, gravure, flexo or digital (toner/inkjet). Digital prints with heavy ink coverage may need specialised digital-grade thermal film.

- Finish and appearance – high-gloss for vivid colours and strong shelf impact, matte for a premium, low-glare “paper-like” look. Soft-touch or anti-scratch films are also available on request.

- Lamination conditions – typical EVA-coated BOPP thermal films run at 90–120 °C depending on film grade, line speed and substrate. Optimal settings should be confirmed on your laminator. :contentReference[oaicite:12]{index=12}

- End-use requirements– food contact, deep creasing, die-cutting, hot stamping, spot UV, etc., may require specific formulations.

Information to include in your enquiry

To help us recommend the right BOPP thermal lamination film quickly, please share:

- Application – e.g. book cover, brochure, folding carton, label, menu, poster.

- Substrate details – paper type and grammage or film type and thickness.

- Required finish – gloss / matte / soft touch / anti-scratch.

- Target thickness – standard range 12–25 μm; please specify if you need single- or double-sided lamination.

- Roll dimensions – width (mm), requested roll OD or length (m), 3″ or 6″ core.

- Laminating machine – type, typical speed and temperature range you currently use.

- Special requirements – food-contact compliance, slip level (COF), dyne level, compatibility with hot stamping or spot UV.

- Order details – expected order quantity per spec and delivery terms/port (e.g. Qingdao).

Send this checklist together with your message, and our engineering team will propose a matching grade and provide a detailed quotation.

Elevate Your Packaging with Premier BOPP Thermal Lamination Film

At CloudFilm, we focus on supplying consistent, high-performance BOPP thermal lamination films backed by clear specifications, rigorous quality control and responsive service.

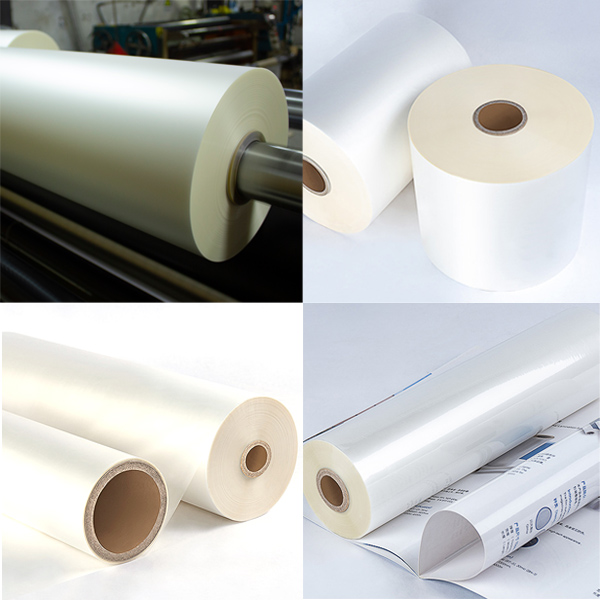

Manufacturing excellenc– modern production lines, controlled EVA coating and strict in-line inspection to ensure stable quality roll after roll.

Reliable delivery – flexible MOQ starting from 500 kg per spec, competitive lead times and export-ready pallet packaging from Qingdao Port.

Technical support – application engineers who understand printing, lamination and converting and can help you optimise film selection and process settings.

Ready to upgrade your lamination performance? Contact CloudFilm to discuss your BOPP thermal lamination film requirements and receive a tailored solution for your project.