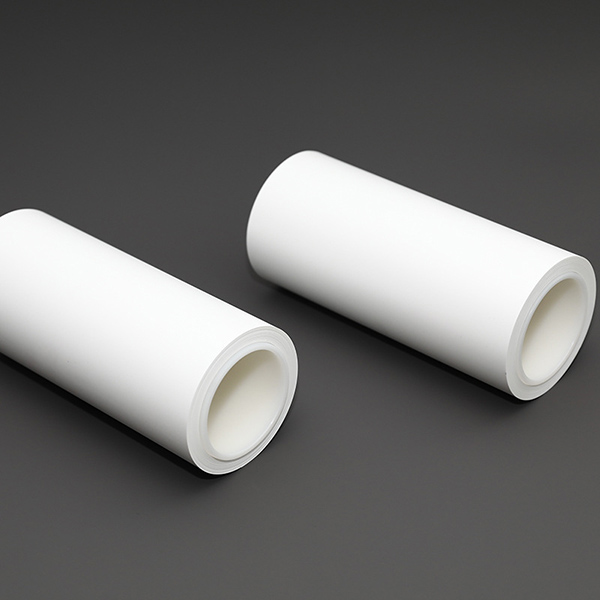

Black PET Film

CloudFilm’s black PET film is an opaque, high-strength polyester film designed for light-blocking packaging, electronic insulation, labels and industrial tapes.

- Superior Light Blocking & UV Shielding – High optical density black PET film with extremely low light transmission for sensitive products that must stay in the dark.

- Mechanical Strength & Dimensional Stability – Excellent tensile strength, tear resistance and flatness for coating, laminating and slitting lines.

- Premium Black Aesthetic – Deep, uniform black color for high-end cosmetics, electronics and premium retail packaging.

- Recyclable Polyester Base – PET substrate that supports recycling streams and brand sustainability goals.

Black PET Film Description

What is Black PET Film?

Black PET film, also known as black polyester film, is a thermoplastic polymer film made from polyethylene terephthalate (PET) with specialized black pigmentation . This versatile material is part of the polyester family and is known for its excellent strength, durability, and chemical resistance .

The black coloration provides exceptional light-blocking properties while maintaining the beneficial characteristics of standard PET films.

Common types of black PET film include:

-

Standard black opaque PET film

-

Conductive black PET film (with EMI shielding properties)

-

Food-grade black PET film

-

Flame-retardant black PET film

-

White-black combination films (one side black, one side white)

Why Choose CloudFilm Black PET Film

CloudFilm black PET film combines high optical density with reliable mechanical performance, making it a robust solution for demanding industrial and packaging environments.

Performance advantages

- High light-blocking and UV protection – Opaque black PET film with strong light and UV shielding to protect light-sensitive products such as electronics, specialty chemicals and premium foods.

- Mechanical strength and flatness – Stable biaxially oriented structure with excellent tensile strength, tear resistance and dimensional stability, suitable for coating, printing, laminating and die-cutting.

- Thermal and chemical resistance – Designed for continuous service in elevated temperatures, while resisting common oils, solvents and moisture in industrial processes.

- Uniform color and appearance – Tight color control ensures consistent deep black tone across batches for brand-critical projects.

Available grades & customization

- Thickness range typically 12–200 μm (other thickness on request).

- Options for antistatic black PET film for electronics and display protection (see Anti Static PET Film).

- Flame-retardant black PET film grades for electrical insulation, label stock and safety-critical parts.

- Laminating to high-barrier structures with Aluminized PET Film or PE/CPP sealant layers for food and medical packaging.

CloudFilm as your manufacturing partner

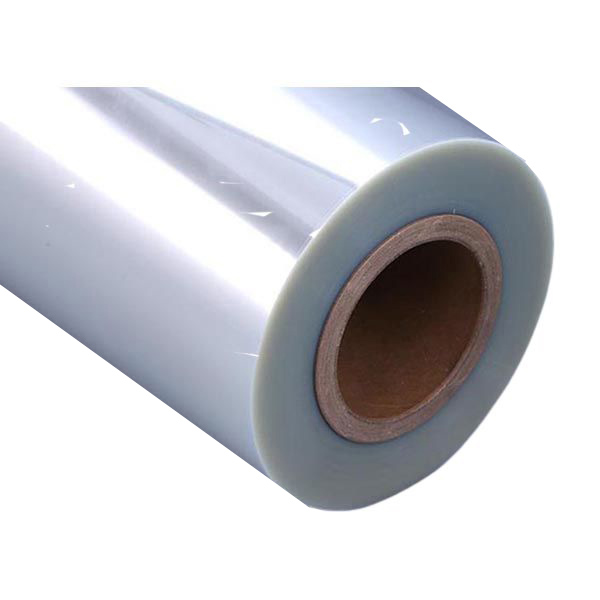

Since 2002, Qingdao Cloud Film Packaging Materials Co., Ltd. has specialized in BOPET films and flexible packaging materials. We supply jumbo rolls and slit rolls of black PET film with:

- Stable quality and traceable production batches.

- Fast sampling and professional technical support for converters and end users.

- Export-ready packaging and documentation for global customers.

• Material: Biaxially oriented polyethylene terephthalate (BOPET) black opaque film.

• Thickness range: Typically 12–200 μm (other thickness can be evaluated on request).

• Color & opacity: Deep black, high optical density for strong light blocking.

• Surface treatment: One-side or two-side treated for printing, coating and lamination, or untreated as required.

• Roll format: Jumbo rolls and slit rolls supplied on 3″ or 6″ paper cores for converters and end users.

• Applications: Light-blocking packaging, labels, industrial and masking tapes, electronic insulation, LCD/backlight shielding films and more.

Get Free Sample of Black PET Film

Ready to test black PET film in your own process? CloudFilm can provide you with sample rolls tailored to your coating, laminating, printing or tape-making lines.

Share your target thickness, width, roll diameter, surface treatment and application (for example: tape backing, LCD backlight shielding, light-blocking food packaging). Our engineers will help you match an equivalent grade or recommend a suitable specification based on your current PET film datasheet.

Send us your inquiry now and we will come back with a detailed proposal, including free sample availability and an indicative lead time for bulk orders.

Black PET Film Applications

Food Packaging

Its deep black color enhances the premium feel of packaging while effectively blocking light and oxygen, helping to preserve food flavor and quality.

Medical Packaging

Used for medical devices and supplies, black PET film provides physical protection and light blocking, with its opacity offering additional privacy protection for products.

High-End Cosmetics Packaging

The deep black appearance lends a sense of luxury and sophistication to products, aligning with premium brand positioning, while its durability helps maintain appearance during transportation and display.

Electronics Shielding & Insulation

When used in electronic components, black PET film provides excellent insulation properties, thermal stability, and light blocking capabilities, also used for making light barrier tapes in LCD and backlight modules.

Industrial Tapes & Labels

Serving as a base material for industrial tapes and insulation tapes, black PET film offers high mechanical strength, tear resistance, and dimensional stability.

Special Functional Applications

Used in microelectronics, optical films, and anti-oxidation films, as well as components requiring high light blocking, wear resistance, and temperature stability, such as camera shutters.

FAQ

Our standard black PET film is available with treated surfaces that provide excellent adhesion for most printing, coating and lamination processes. For special inks or coatings, we can recommend the right surface treatment based on your process.

We use controlled pigment masterbatch systems, precise extrusion conditions and continuous online monitoring to keep the deep black color uniform from batch to batch. For long-term outdoor or high-temperature use, we can recommend grades with improved color stability.

In many applications, black PET film can operate continuously in elevated temperatures typical for PET (for example up to around 120–150°C, depending on grade and dwell time). However, the exact allowable temperature and duration depend on your specific structure and process, so please share your conditions and we will confirm with a suitable grade and TDS.

Standard black PET film grades are typically available from 12–200 μm. We supply jumbo rolls and slit rolls in widths compatible with common coating, laminating and slitting lines. Please let us know your required thickness, width and roll diameter so we can check availability or recommend a close equivalent.

Black PET film can be produced in food-contact grades that comply with relevant regulations (for example FDA or EU) when the correct raw materials and structures are selected. If you plan to use black PET film in direct or indirect food contact, please tell us your target market and regulatory requirements so we can recommend a suitable grade and provide the corresponding documentation (such as DoC / COA).

Yes. Many customers use black PET film as a backing for masking tapes, industrial and electrical tapes, nameplates and labels, as well as for insulation and light-blocking films in electronic devices. For applications requiring static control, you can also consider our Anti Static PET Film grades.

Black PET film can be laminated with Aluminized PET Film, PE, CPP and other substrates to build high-barrier or heat-sealable structures. Please send us your current laminate structure or target barrier requirements, and we will suggest a suitable design.

For standard black PET film specifications, the minimum order quantity and lead time are similar to our other PET films. As a guideline, standard orders can often be arranged within a typical PET film MOQ and lead time window, while custom thickness, color or surface treatments may require longer. Share your target specification and annual volume and we will confirm MOQ and delivery time.

Related News

BOPET film is one of the most important polyester films used in modern flexible packaging. It combines high strength, […]

Introduction – Why Are PET and CPP Always Compared? 1.1 Setting the Scene: The “Century-Old Dilemma” of Packaging […]

In the world of engineering, manufacturing, and product design, precision is paramount. When working with materials like PET (Polyethylene […]

Introduction If you’re a product manager, packaging engineer, or procurement specialist researching high-performance packaging solutions, your search has […]

Why PET ALOx Matters For Modern Packaging In food, pharmaceutical and technical packaging, buyers are under pressure to […]

Introduction Biaxially Oriented Polyethylene Terephthalate (BOPET) film is one of the most versatile and widely used plastic […]

Heat sealable PET films have become one of the most important materials in modern flexible packaging. From ready-meal trays […]

Although PETG and PET differ by only one letter “G” in their names, in the field of modern material science, […]