How To Order APET Film From CloudFilm

CloudFilm makes it simple to move from APET tray ideas to stable, repeatable production. Whether you are a thermoformer, a food packer or a medical packaging converter, our team can help you define the right film and start your project with lower risk.

Step-By-Step Ordering Guide

- Step 1 – Share Your Project Details

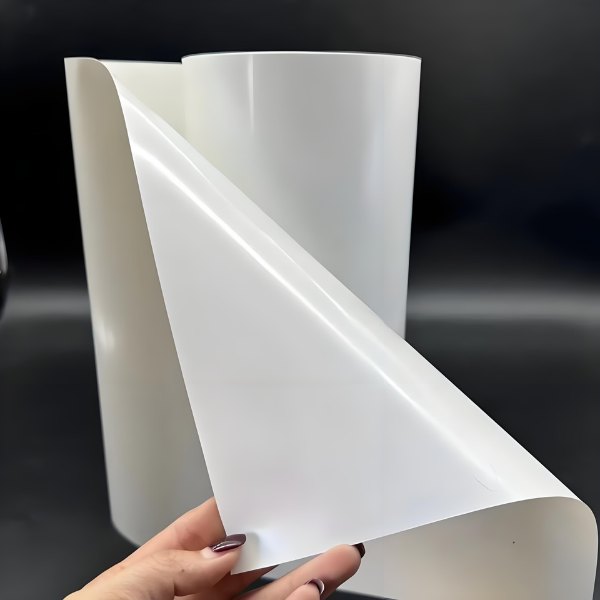

Tell us about your application (food, medical, electronics, display), target tray size and depth, required thickness, width and color, as well as whether you need rolls or sheets. - Step 2 – Choose Structures And Matching Films

Our engineers will recommend suitable APET specifications and, if needed, matching top-web solutions such as PET/PE lidding film or PVDC PET high-barrier film, so you can build complete tray and lidding structures with CloudFilm. - Step 3 – Trial Sheets, Samples And Quotation

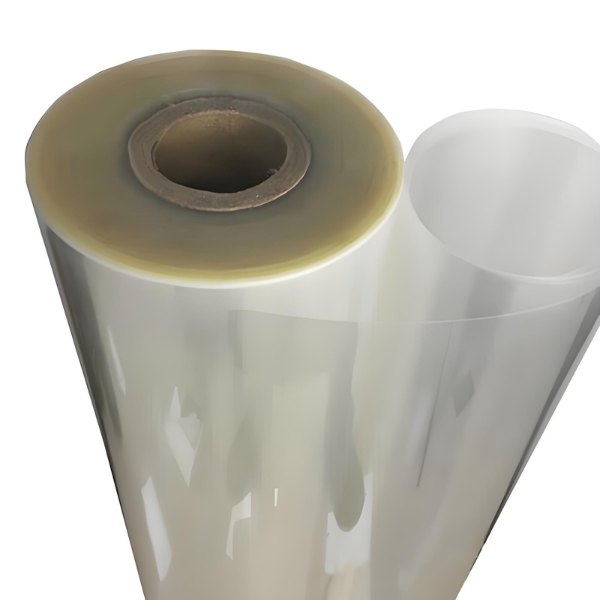

We arrange APET sample rolls or sheets for thermoforming trials, and provide a clear quotation based on your order quantity, packaging requirements and destination port. - Step 4 – Order Confirmation And Delivery

After confirming specifications and price, we schedule production, carry out full QC inspections and prepare export-ready packing. You will receive regular updates on lead time, loading and shipment.

What You Can Expect From CloudFilm

- Technical Support From PET Packaging Experts – Advice on APET thickness, forming conditions and sealing structures for your specific lines.

- Consistent Quality For Export Projects – Controlled thickness, clarity and mechanical strength for long-term repeat orders.

- Flexible Logistics – From trial quantities to full-container loads, shipped to your required seaport with export documentation.

- Clear Documentation – Certificates, test reports and compliance documents to support your internal approvals and customer audits.