Mylar Properties: A Practical Guide for Packaging and Industrial Uses

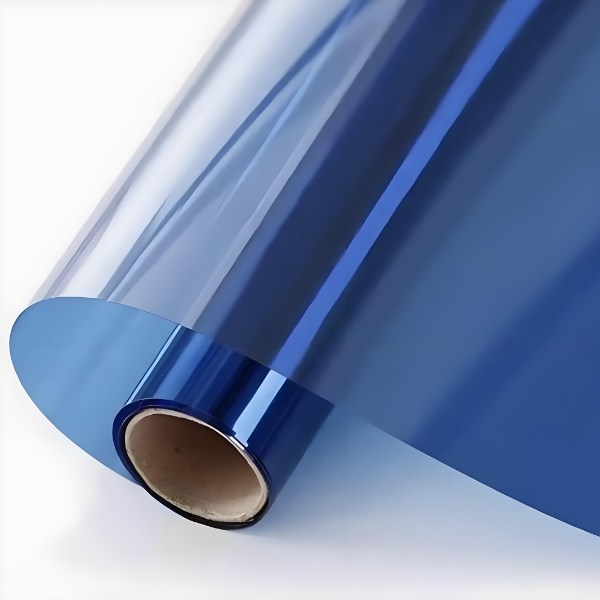

“Mylar” is commonly used as a shorthand for biaxially oriented polyethylene terephthalate (BoPET) film. While “Mylar” originated as a brand name, the material behind the term is the same high-performance PET film known for its balance of mechanical strength, dimensional stability, barrier performance, dielectric properties, and surface treatability.

This guide explains how Mylar’s structure translates into real-world performance, what trade-offs matter for packaging converters and engineers, and how to select the right grade for your application. We’ll also include simple, indicative charts to help you visualize trends that typically guide material choice and process setup.

What Is Mylar (BoPET) and Why It’s Different

BoPET is PET film that is stretched in both machine and transverse directions. Biaxial orientation increases crystallinity and aligns polymer chains, which delivers high tensile strength, modulus, and dimensional stability compared with many commodity polyolefin films. The film exhibits low creep under sustained load, aiding tight gauge control during high-speed converting and long-term stability in industrial laminates.

For packaging, converters value Mylar for clarity, printability after surface treatment (corona or primer), and consistent thermal behavior that supports precise sealing windows when paired with appropriate sealant layers. In short, Mylar’s microstructure yields a macro-level mix of stiffness, consistency, and process latitude that’s hard to replicate with a single alternative.

Mechanical Properties: Strength, Stiffness, and Toughness

The biaxial orientation of Mylar delivers high tensile strength and stiffness that translate directly to excellent dimensional control during printing, lamination, and slitting. You can maintain registration at speed, keep webs flatter, and reduce edge weave relative to softer films. Mylar also brings good puncture resistance for many pouch formats and enhances print fidelity because the stiffer base limits micro-stretching that can blur fine detail.

Thickness selection influences both handling and tactile feel. Thinner gauges support light-weighting and cost reduction while maintaining adequate stability for many overwraps or surface-print applications. Thicker gauges deliver more board-like stiffness, enhance mechanical protection, and improve stand-up pouch posture. In laminated structures—such as Mylar/PE— the Mylar layer provides rigidity and optical stability, while the sealant defines sealing performance and machinability at the packer.

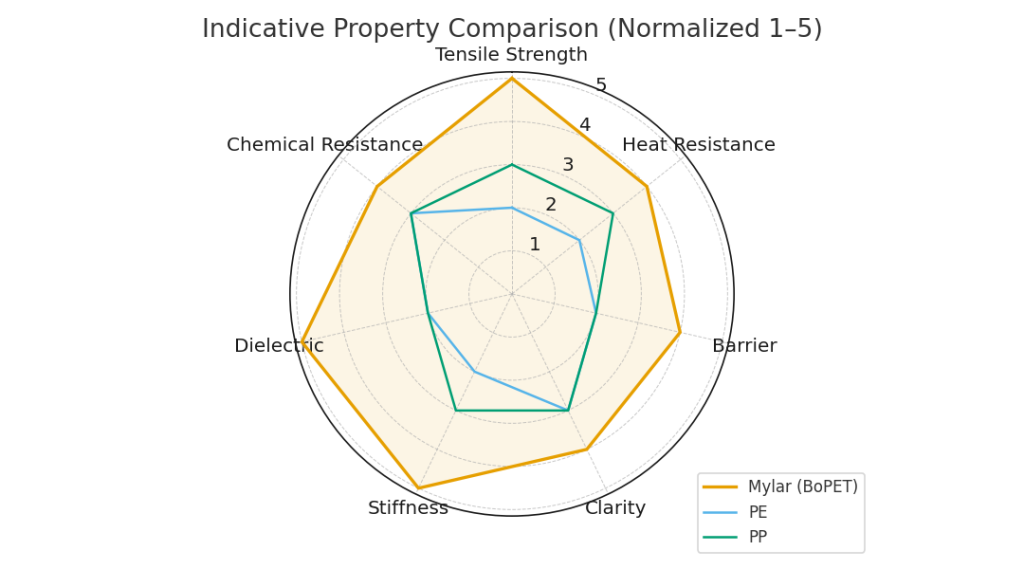

Figure: Normalized property comparison—Mylar vs PE vs PP (indicative trends).

Figure: Normalized property comparison—Mylar vs PE vs PP (indicative trends).

Thermal Behavior: From Shrinkage Control to Heat Resistance

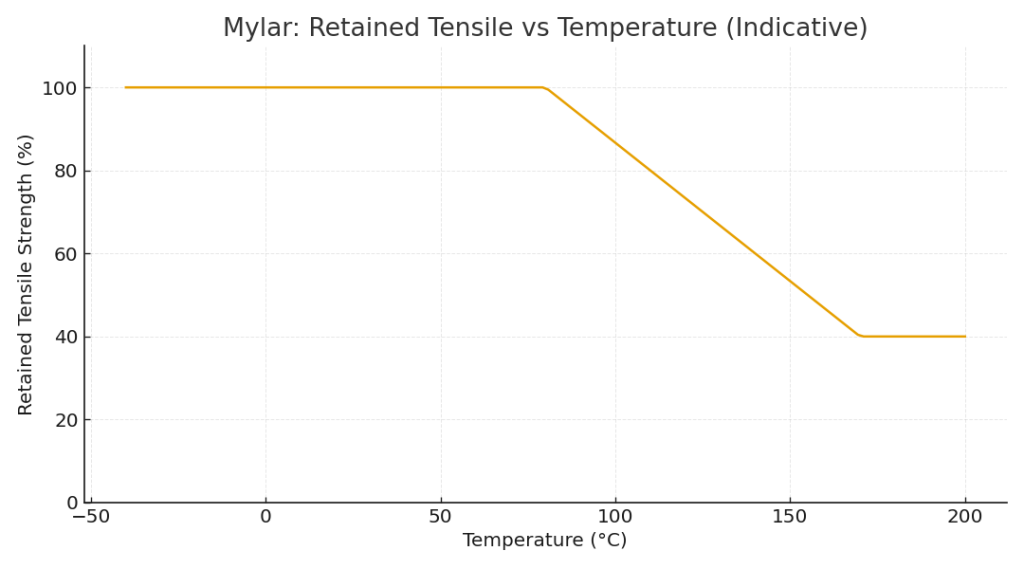

Two thermal aspects matter most on converting lines: retained tensile strength as temperature rises and free shrinkage. Mylar typically retains useful stiffness and strength across a broad converting window. Heat-set grades further reduce shrinkage for dimensional stability in demanding processes such as multi-pass printing or high-temperature drying.

While Mylar’s melting point sits well above common sealing and drier temperatures, the glass transition temperature is much lower; in practice, this means you’ll enjoy stable handling at typical oven conditions but should still validate your thermal profile to avoid distortion, especially on delicate, high-coverage graphics.

For pouch converting, consistent thermal behavior helps keep sealing jaws, hot bars, or IR tunnels operating within a predictable window. You can tune tension, dwell, and temperature without chasing film growth or shrink spikes. In labeling or lidding, lower free shrinkage helps maintain flatness and tight die-cutting tolerances.

Figure: Retained tensile strength vs temperature—trend line to illustrate behavior, not a specification.

Figure: Retained tensile strength vs temperature—trend line to illustrate behavior, not a specification.

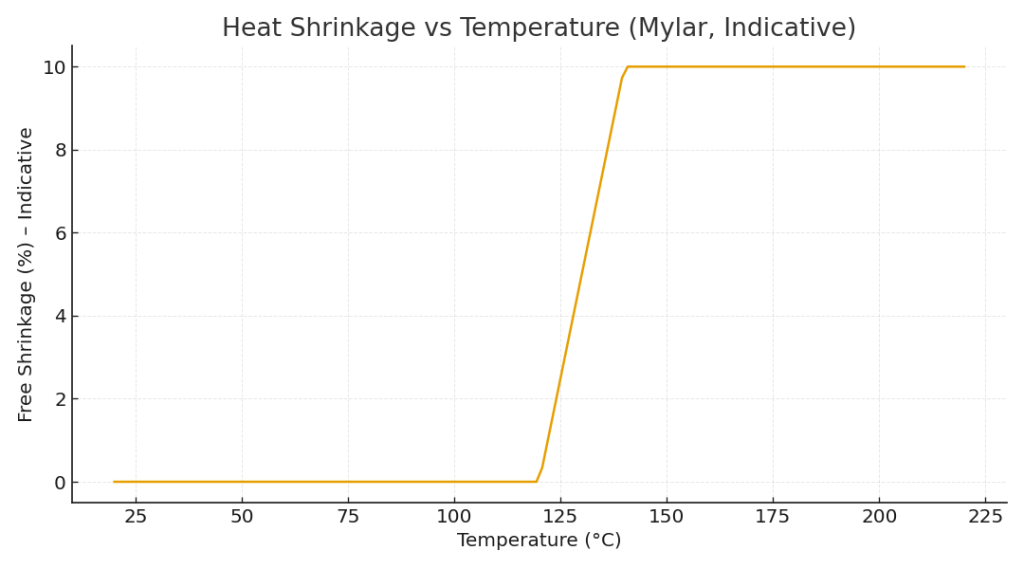

Figure: Free shrinkage vs temperature—low until elevated temperatures; heat-set grades shrink less.

Barrier Performance: Oxygen and Moisture

Clear Mylar provides moderate oxygen and moisture barrier, sufficient for many dry foods, powders, and non-critical aroma applications when paired with suitable sealants. Metallized Mylar dramatically improves barrier, which is why it’s widely used for coffee, snacks, powdered beverages, and products where aroma retention and shelf-life are important.

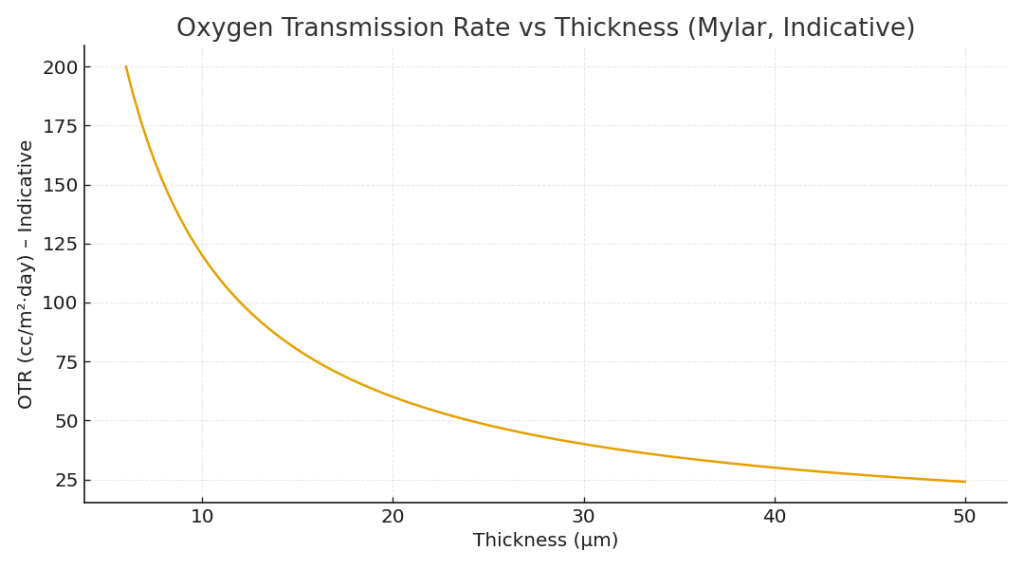

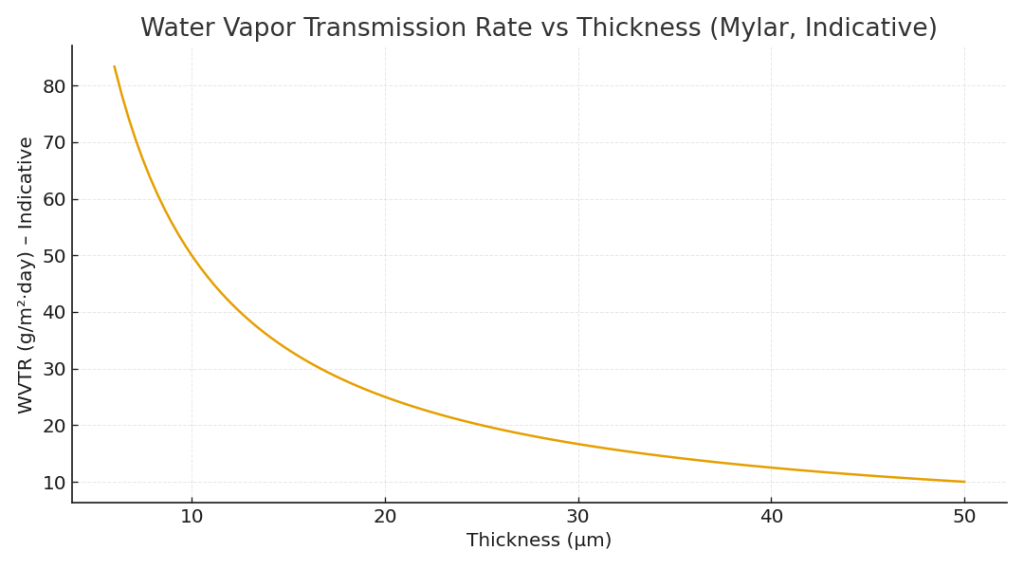

Barrier scales with thickness and depends on processing conditions such as relative humidity and temperature, as well as the laminate design (adhesives, tie layers, and sealants). Always validate with your target shelf life, distribution environment, and regional regulatory requirements.

Figure: Oxygen transmission rate (OTR) generally decreases as thickness increases.

Figure: Water vapor transmission rate (WVTR) also trends downward with increasing thickness.

Electrical and Chemical Properties

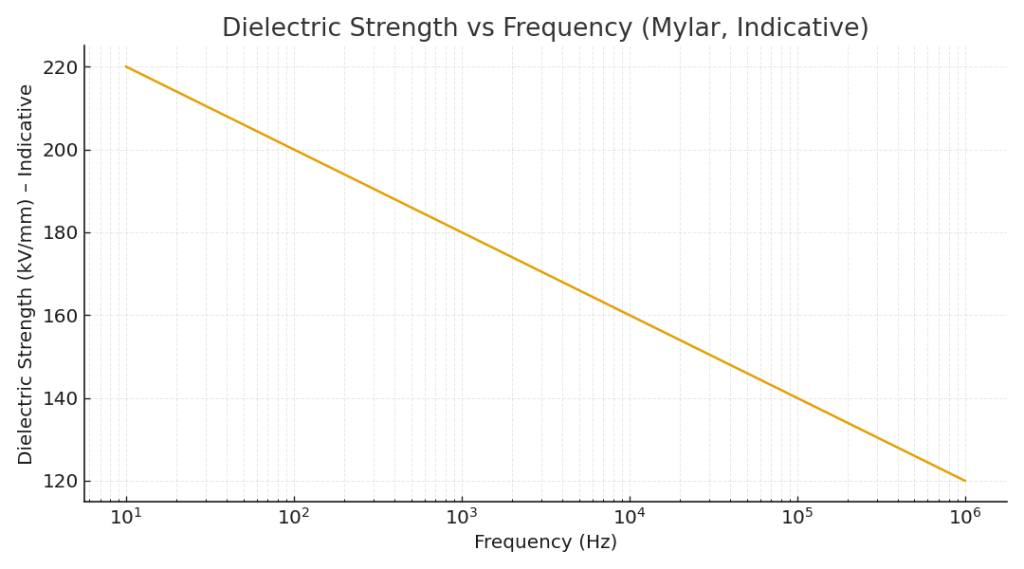

Beyond packaging, Mylar’s dielectric strength and insulation reliability make it a staple in electrical and electronic components (insulation films, capacitors, and slot liners). The film’s consistent gauge and surface cleanliness support reliable adhesion with resins or adhesives in composite structures. Chemically, Mylar shows good resistance to many solvents and oils and reasonable hydrolytic stability under typical service conditions.

However, strong alkaline environments or prolonged high-temperature/high-humidity exposure can affect long-term properties—always test for your exact scenario, especially for mission-critical insulation or protective layers.

Figure: Dielectric strength vs frequency—illustrative trend used in early design screening.

Surface Options and Converting Friendliness

Converters typically choose among untreated, corona-treated, or primer-coated Mylar depending on ink systems (solvent, water, UV) and lamination method (solvent, solventless, extrusion). Specialty grades include matte, heat-sealable, white/opaque, and metallized films.

When designing a laminate, match the coefficient of friction (COF) and seal window across the web: Mylar contributes stiffness, dimensional stability, and printability; the sealant (e.g., PE or sealable PET) defines machinability, hot-tack, and low-temperature seal performance. For high-speed form-fill-seal lines, tuning COF and web path roll coverings often unlocks significant throughput without sacrificing registration.

Mylar vs PE, PP, and Nylon: How to Choose

-

Versus PE: Mylar offers much higher stiffness and strength, better dimensional control, and higher temperature tolerance. PE wins on sealability, cost, and flexibility, and is the default inner sealant for many pouches.

-

Versus PP: PP is lighter and lower cost for many jobs. Mylar brings stability, print crispness, and better heat resistance—useful for surface-print designs and structures needing extra rigidity.

-

Versus Nylon (BOPA): Nylon excels in toughness and puncture resistance with good oxygen barrier but is more sensitive to humidity. Mylar offers stable mechanics and clarity with versatile surface options and is often preferred where print quality and flatness dominate.

Rule of thumb: Use Mylar to add rigidity, print quality, and dimensional stability; then tune overall barrier with metallization or dedicated barrier layers when shelf-life targets require it.

Selection Checklist (For Converters and Engineers)

-

Define the primary need: clarity vs matte feel, stiffness, insulation, or barrier.

-

Set barrier targets; decide whether metallized Mylar is necessary.

-

Choose thickness for handling, shelf feel, and load-bearing requirements.

-

Match COF and seal window with the chosen sealant layer and equipment.

-

Confirm print method (gravure/flexo/digital) and the surface treatment required.

-

Validate the thermal profile (driers/ovens) for shrinkage, curl, and registration.

-

Run shelf-life and distribution tests where oxygen, moisture, or aroma is critical.

-

Document regulatory and food-contact needs by region and application.

FAQs

Q1. Is Mylar recyclable?

Mylar is PET-based. Recyclability depends on local collection and sorting infrastructure and the laminate design. Mono-material PET structures are improving compatibility in some regions; always verify with local programs.

Q2. Can Mylar replace aluminum foil?

Not directly for the highest barrier needs. Metallized Mylar is commonly used where elevated barrier is required without foil, but you must still confirm oxygen and moisture targets and run shelf-life tests.

Q3. What gauges are commonly used?

Packaging applications often use 12–36 µm, though specialty films may be <10 µm and industrial grades can exceed 100 µm. Choose based on process conditions, stiffness targets, and line capability.

Q4. How do I improve sealability in a Mylar structure?

Use dedicated sealant layers (e.g., PE or sealable PET) and tune COF and seal window across the laminate. Mylar contributes stability and print clarity, while the sealant drives machinability and seal performance.

Key Takeaways & Next Steps

-

Mylar (BoPET) balances mechanical strength, thermal stability, moderate barrier, dielectric performance, and surface versatility.

-

Use metallization or barrier partners for enhanced shelf-life when needed.

-

Match thickness, surface treatment, COF, and seal window to your equipment and product.

-

Share your spec sheet or request a trial roll—a short, well-planned plant trial typically accelerates dial-in and reduces total project time.

Ready to evaluate Mylar? Send your target specs or sample request to [email protected] and we’ll propose structures tuned to your line, graphics, and shelf-life goals.