Introduction: Why Compare Nylon and EVOH?

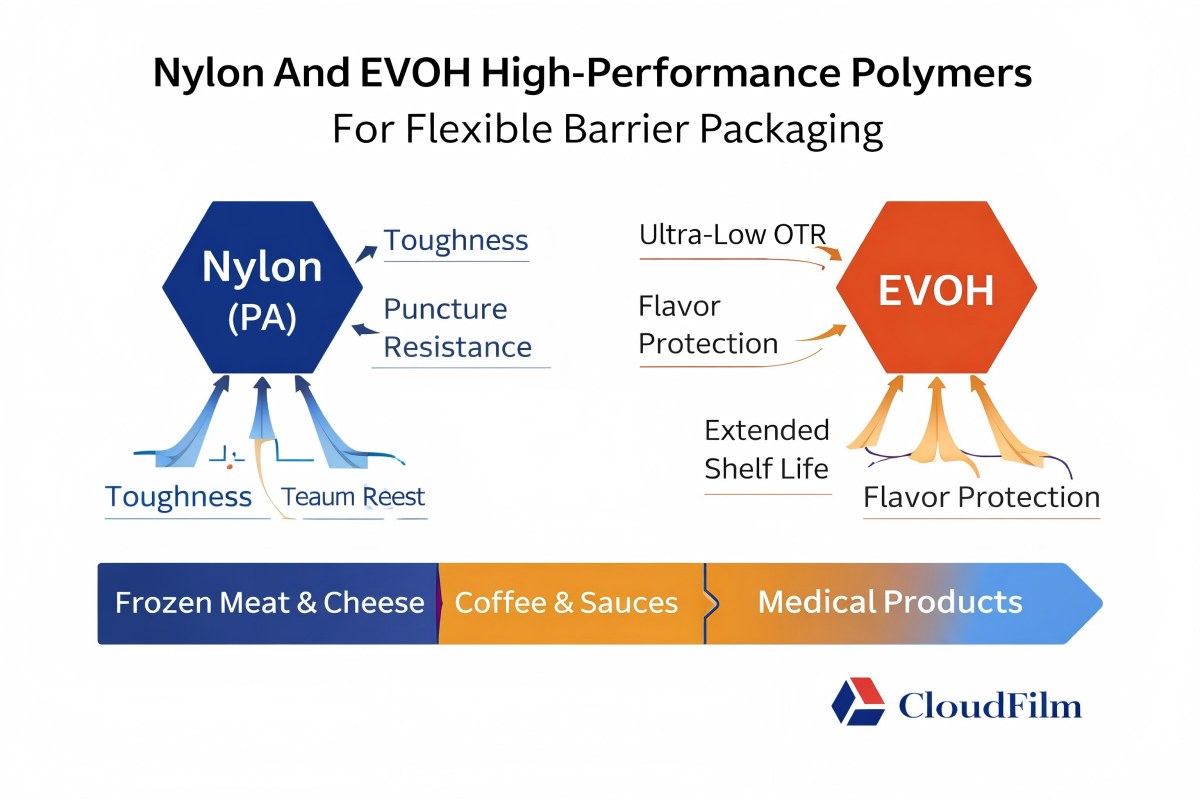

Nylon (Polyamide, PA) and EVOH (Ethylene Vinyl Alcohol Copolymer) are two widely used high-performance polymers in the packaging and industrial materials sectors. Both materials offer unique properties that make them suitable for demanding applications such as food packaging, medical products, and industrial films.

However, their distinct characteristics often leave engineers and product designers wondering which material to choose—or whether to combine them.

In flexible packaging, nylon usually appears as biaxially oriented BOPA film or cast nylon film, while EVOH is used as a thin barrier core layer in co-extruded high-barrier films and laminates.

Background

Nylon and EVOH are both high-value materials compared with basic polyolefins, so choosing between them has a direct impact on performance, cost, and line efficiency.

Purpose of This Article

This article provides a systematic comparison of nylon and EVOH across physical, chemical, mechanical, and barrier properties. It also evaluates their suitability in various application scenarios and offers practical selection guidance to help readers make informed material decisions.

From CloudFilm’s perspective as a flexible packaging film manufacturer, this comparison is based on real project experience with BOPA, cast nylon, PA/PE, PE PA PE, co-extruded EVOH films and PP EVOH PP sheets, helping buyers quickly shortlist workable structures instead of guessing on their own.

If you need deeper background on each material, you can also refer to CloudFilm’s guides Understanding Nylon Film Properties: A Comprehensive Guide and EVOH Barrier: Guide To Properties, Applications & Selection.

{ Both Nylon and EVOH are High-performance Polymers }

Material Overview

Nylon (Polyamide, PA)

Nylon is a semicrystalline polymer known for its excellent mechanical strength, abrasion resistance, and flexibility. Common types include PA6 and PA66, which are widely used in both flexible and rigid packaging.

In practical packaging structures, nylon is mainly supplied as biaxially oriented BOPA film and cast nylon film, and is frequently combined with PE seal layers in PA/PE and PE PA PE laminates to deliver toughness, puncture resistance and reliable sealing on thermoforming and vacuum-bag lines.

EVOH (Ethylene Vinyl Alcohol Copolymer)

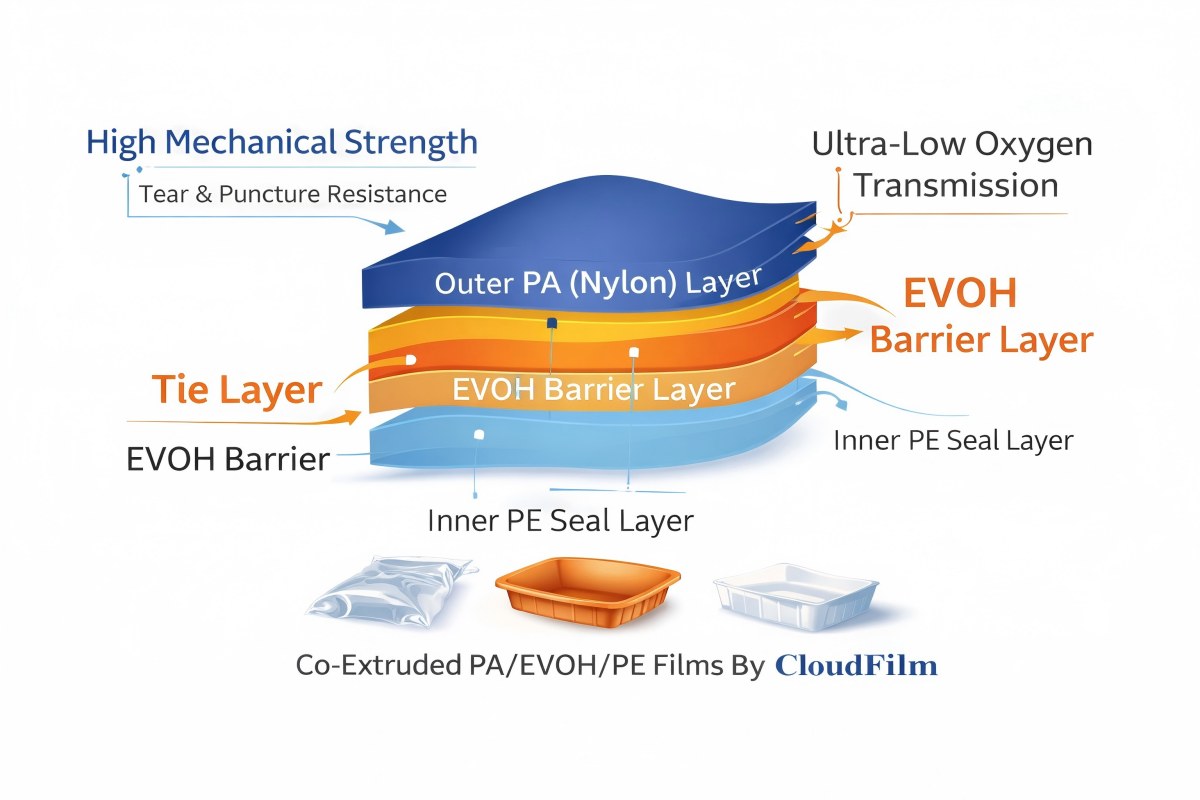

EVOH is a copolymer with outstanding barrier properties, especially against oxygen and other gases. It is often used in multilayer packaging structures where preserving product freshness is critical.

Within CloudFilm’s portfolio, EVOH is usually embedded as the barrier core in co-extrusion EVOH film, EVOH bags and PP EVOH PP barrier sheets , protected by PA, PE or PP outer layers that provide toughness, seal strength and moisture buffering.

Because EVOH is highly efficient even in thin layers, it is normally applied at only a few microns in PA/EVOH/PE or PE/EVOH/PE structures, keeping total thickness and cost under control while dramatically boosting shelf life.

Performance Comparison

1. Barrier Properties

- Nylon: Moderate oxygen barrier; good resistance to oils and aromas.

- EVOH: Exceptional oxygen barrier under dry conditions; barrier performance decreases with humidity.

At comparable thickness, EVOH’s oxygen barrier can be tens to hundreds of times higher than oriented nylon, which is why EVOH is often described as the “king of barrier” for food, coffee, sauce and medical packaging.

In CloudFilm’s high-barrier product range, EVOH is typically used as a 3–15 μm core layer inside PA/EVOH/PE, PE/EVOH/PE or PP/EVOH/PP co-extruded films to achieve very low OTR while keeping the structure thin and cost-effective.

2. Mechanical Properties

- Nylon: High tensile strength, puncture resistance, and flexibility.

- EVOH: More brittle and less flexible; typically used in combination with other polymers.

In thermoforming, vacuum bags and deep-draw applications, nylon plays the role of the “muscle layer”, providing formability and resistance to bone puncture, while EVOH must always sit between tougher layers and is rarely exposed to the surface.

3. Thermal Resistance

- Nylon: Withstands high temperatures, suitable for retort and boiling applications.

- EVOH: Limited thermal stability; not ideal for high-heat processing unless protected in a multilayer structure.

For retort pouches and trays such as PET/PA/RCPP or PA/AL/RCPP, nylon remains the primary structural material, whereas EVOH is more often specified in chilled, pasteurized or ambient applications where ultra-high oxygen barrier is needed but full retort is not.

4. Moisture Sensitivity

- Nylon: Hygroscopic; absorbs moisture which may affect dimensional stability.

- EVOH: Highly sensitive to moisture; barrier efficiency drops in high humidity environments.

To control humidity effects, converters generally protect EVOH by placing it at the center of the structure and sometimes pairing it with outer nylon, PE or PVDC-coated films so that barrier remains stable even under cold-chain and high-humidity conditions.

5. Chemical Resistance

- Nylon: Resistant to oils, greases, and many organic solvents.

- EVOH: Susceptible to degradation when exposed to strong acids or bases.

{ Nylon/EVOH Co-extrusion }

Application Scenarios

1. Food Packaging

- Nylon: Used in vacuum packaging, boil-in-bag products, and frozen food packaging.

- EVOH: Preferred for oxygen-sensitive products such as coffee, cheese, and processed meats.

In CloudFilm’s food projects, nylon-based laminates such as BOPA/PE, BOPA/CPP, PA/PE and PE PA PE are widely used for frozen meat, sausages, cheese and ready meals, while EVOH-based co-extruded films and EVOH bags are selected when customers require 6–24 months of chilled or frozen shelf life for export markets.

2. Medical Packaging

- Nylon: Used in sterile medical device packaging due to its durability and puncture resistance.

- EVOH: Used in high-barrier medical pouches to maintain sterility.

For medical and pharmaceutical customers, CloudFilm often combines nylon or PET with EVOH cores and aluminium foil to build high-barrier pharmaceutical pouches that protect APIs, diagnostics and gels from both oxygen and moisture throughout sterilization, storage and transport.

3. Industrial Films

- Nylon: Common in heavy-duty sacks, protective films, and laminates.

- EVOH: Used in specialty films requiring high gas barrier performance.

In industrial and chemical packaging, nylon layers mainly contribute puncture resistance and temperature stability in heavy-duty sacks and protective films, while EVOH layers are specified when liquid chemicals, agrochemicals or industrial products are highly sensitive to oxygen or solvent permeation.

Composite Structures

1. Nylon/EVOH Composites

In many high-end applications, nylon and EVOH are combined in multilayer films to leverage the strengths of both materials. Typical structures include PA/PE/EVOH/PE or similar combinations.

Depending on forming depth, sealing requirements and recycling targets, converters may also use PA/EVOH/PE, PE/EVOH/PE or PP/EVOH/PP structures to balance stiffness, formability, barrier and cost.

2. Processing Methods

- Co-extrusion

- Dry lamination

- Coating

CloudFilm can supply these nylon+EVOH multilayers either as ready-to-use rollstock for thermoforming, vacuum bags and lidding films, or as pre-made bags and pouches, helping customers shorten development cycles and reduce trial-and-error on their own lines.

{ Nylon/EVOH Composite Materials Possess Both Mechanical Strength and Barrier Properties }

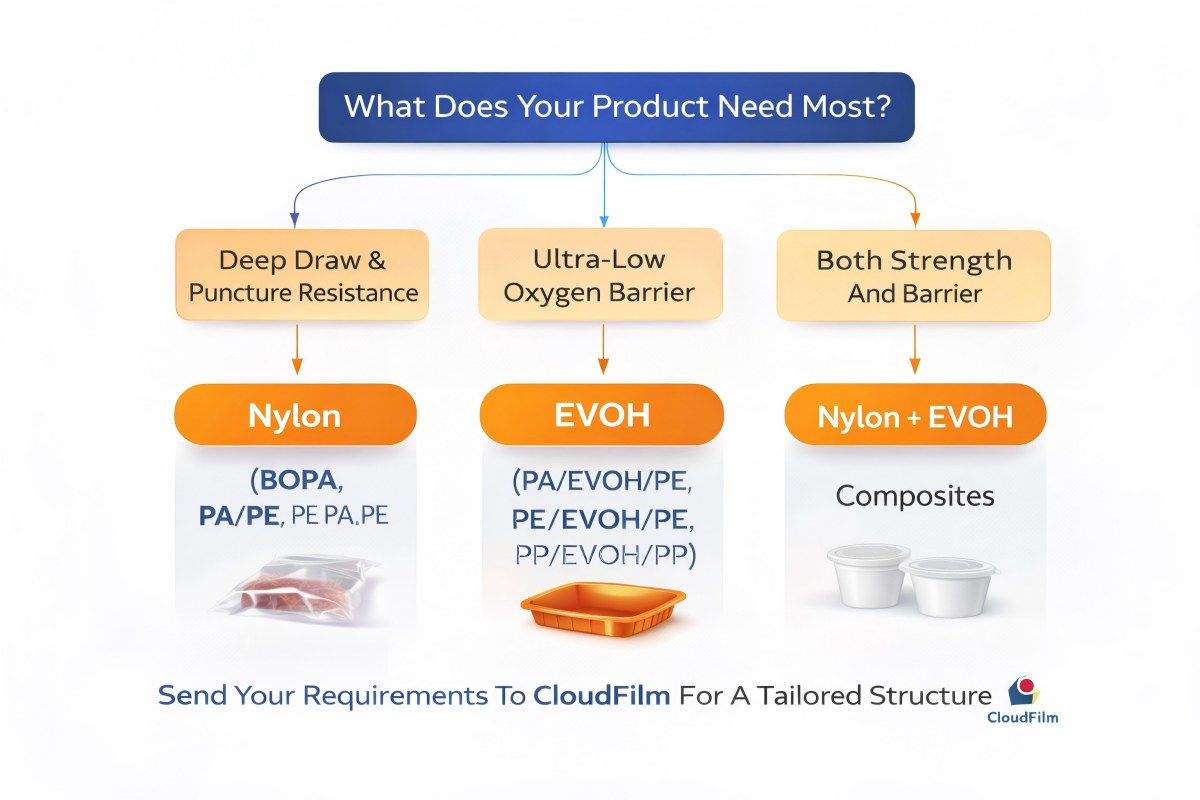

Material Selection Guide

1. Choose Nylon When:

- High mechanical strength and puncture resistance are required.

- The product will undergo high-temperature processing.

- Cost efficiency is a priority.

Typical nylon-rich structures include BOPA/PE, BOPA/CPP, PA/PE and PE PA PE, which CloudFilm can customize in thickness, width and forming behavior to match your vacuum-bag, thermoforming or lidding lines.

2. Choose EVOH When:

- Superior oxygen barrier is critical.

- The product is sensitive to oxidation and spoilage.

- A high-value product justifies the added material cost.

EVOH-based structures such as PA/EVOH/PE, PE/EVOH/PE and PP/EVOH/PP are especially suitable for coffee, sauces, cheese, meats and medical products where extending shelf life or protecting sensitive ingredients delivers clear commercial value.

3. Choose a Composite When:

- Both mechanical strength and barrier properties are needed.

- You need to balance performance and cost effectively.

In many real projects, CloudFilm designs nylon+EVOH composites that combine formability, stiffness, seal integrity and barrier, then validates them through sample rolls and pilot runs before commercial scale-up.

If you are unsure which route to take, simply share your product type, filling temperature and target shelf life with CloudFilm’s engineers—they will quickly narrow down 2–3 feasible structures for you to test.

How CloudFilm Supports Nylon And EVOH Packaging Projects

CloudFilm has been manufacturing flexible packaging films since 2002, supplying BOPA, BOPET, BOPP, PE, CPP and high-barrier co-extruded films to customers in more than 30 countries. This experience allows our team to compare nylon and EVOH options using real performance data instead of theory alone.

For nylon-focused solutions, CloudFilm provides BOPA film, simultaneous BOPA film, cast nylon film and PA-based laminates such as PA/PE and PE PA PE film, covering vacuum bags, thermoforming webs and forming/non-forming top & bottom films.

For EVOH-centered projects, CloudFilm offers co-extrusion EVOH film, EVOH bags and PP EVOH PP sheets, as well as PE-EVOH-PE mono-PE concepts described in our article Unveiling The Secrets Of PE-EVOH-PE Film.

A typical development workflow with CloudFilm looks like this: you share your product (meat, cheese, coffee, medical device, chemical, etc.), filling conditions, target shelf life and approximate volume; our engineers propose 1–3 nylon, EVOH or composite structures, send trial rolls or sample bags, and then help you fine-tune thickness, forming depth and sealing windows based on line trials.

Whether you are upgrading from conventional PA/PE vacuum bags to EVOH bags, or comparing aluminium foil laminates with nylon/EVOH high-barrier films, CloudFilm can provide data-driven recommendations and competitive quotations from its China-based production base.

FAQ: Nylon vs EVOH In Flexible Packaging

Q1. Is Nylon Or EVOH Better For Vacuum Packaging Fresh And Frozen Meat?

A1. For bone-in or sharp-edged products, nylon-based structures such as BOPA/PE, PA/PE or PE PA PE are usually preferred because they offer superior puncture resistance and deep-draw formability.

EVOH is often added as a thin core layer (PA/EVOH/PE or PE/EVOH/PE) when longer chilled or frozen shelf life is required, for example in export meat projects. CloudFilm routinely supplies both standard PA/PE and EVOH high-barrier EVOH bags for these applications.

Q2. When Should I Choose Nylon Instead Of EVOH For Retortable Packaging?

A2. In retort pouches and trays, nylon plays the structural role because it can withstand high temperatures and pressure during sterilization, especially in structures like PET/PA/RCPP or PA/AL/RCPP. EVOH, by contrast, is more sensitive to heat and moisture, so it is better suited for chilled, pasteurized or non-retorted high-barrier packs.

If your pack must pass 121–135 °C retort, prioritize nylon-based structures and consult CloudFilm for detailed retort CPP and PA-based laminate options.

Q3. How Do Nylon And EVOH Behave In Deep-Draw Thermoforming?

A3. Nylon exhibits excellent drawability and maintains strength in the corners of deep-draw trays, making PA/PE and PE PA PE films popular choices for thermoforming bottom webs. EVOH on its own does not draw well and must remain thin and well-protected inside multi-layer structures.

CloudFilm’s co-extruded PA/EVOH/PE forming films balance draw depth, barrier and seal strength for high-value chilled meats, cheeses and ready meals.

Q4. Can Nylon And EVOH Help Me Move Toward More Sustainable Packaging?

A4. Yes, when used carefully. Nylon generally complicates recycling in many mono-material PE or PP streams, whereas PE-EVOH-PE concepts keep the overall structure PE-dominant while adding a thin EVOH barrier core.

CloudFilm’s article Unveiling The Secrets Of PE-EVOH-PE Film explains how to design such structures, and our mono-material packaging blog further discusses how MDO PE, BOPE and PE/EVOH/PE films fit into future recycling systems.

Q5. Which Material Is More Cost-Effective: Nylon Or EVOH?

A5. There is no single answer. Nylon is generally cheaper per kilogram than EVOH and contributes mechanical strength, so PA/PE structures often deliver an attractive cost-performance ratio. EVOH is more expensive but can dramatically extend shelf life in oxygen-sensitive products, reducing product waste and returns.

CloudFilm typically compares both options using your actual product value, target shelf life and logistics conditions, then recommends either nylon-only, EVOH-enhanced or nylon+EVOH composite structures.

Q6. How Can I Quickly Get A Nylon Or EVOH Structure Recommendation From CloudFilm?

A6. The fastest way is to send CloudFilm a short project brief with your product type (meat, cheese, coffee, medical, chemical, etc.), target shelf life, filling temperature, pack format (bag, pouch, tray, lid) and estimated monthly volume.

Using this information, our engineers will shortlist 2–3 structures and reply with suggested films—such as BOPA/PE, PA/PE, PA/EVOH/PE or PE/EVOH/PE—along with quotations and sample options. You can start this process directly via the Contact CloudFilm page.

Conclusion

Nylon and EVOH each have distinct advantages and limitations. While nylon excels in mechanical strength and thermal resistance, EVOH offers unmatched barrier properties.

{ Select the Appropriate Material Based on Specific Requirements }

In many modern packaging applications, a composite structure that combines both materials delivers the best overall performance. Understanding the specific requirements of your application is key to selecting the right material.