CloudFilm Support from Specification to Logistics

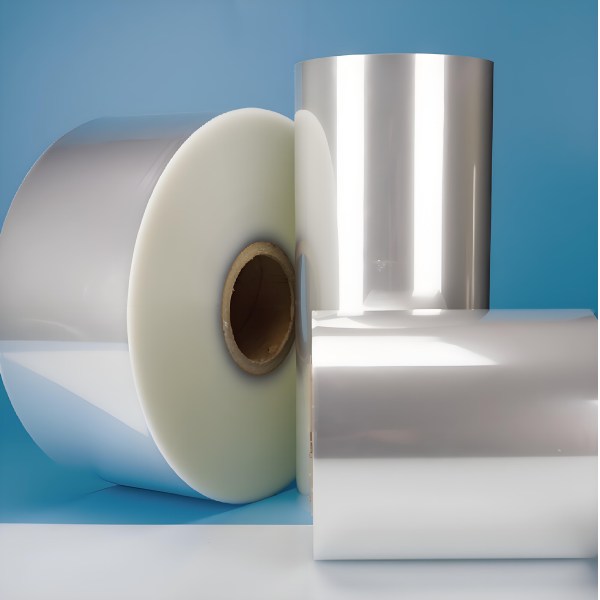

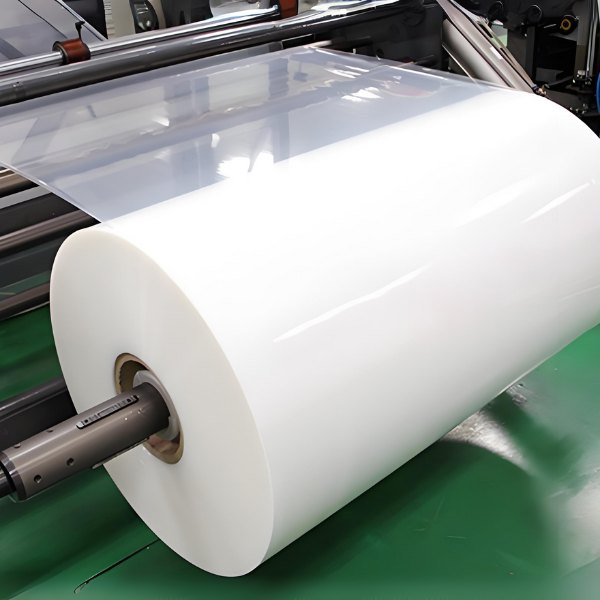

Since 2002, CloudFilm has focused on manufacturing and exporting flexible packaging films from Qingdao, China. For 12µm BOPP projects, our team supports you from early specification through to long-term supply. Typical support includes:

- Matching film grade to product, line speed and sealing window

- Advising on print sequence and lamination structure with your partners

- Providing documentation and test reports where required

- Planning slitting, palletizing and container loading for your routes

Whether you are qualifying a new supplier or optimizing an existing structure, CloudFilm aims to make 12µm BOPP a low-risk, high-value part of your packaging program.