Why Choose CloudFilm As Your Packaging Film Roll Partner?

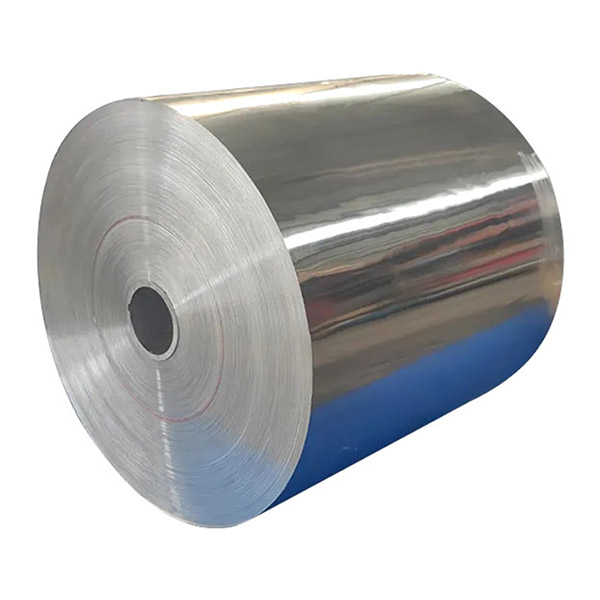

Since 2002, CloudFilm has focused on manufacturing and supplying flexible packaging films, including BOPP, BOPET, BOPA, PE and high-barrier laminates. This gives you a single partner who understands both materials and real production lines.

Instead of offering only standard grades, we work with your product managers, packaging engineers and converters to design packaging film rolls that match your product, machinery and market positioning. Our team can review your current film specifications, samples or drawings and propose equivalent or upgraded structures.

CloudFilm operates modern film production and converting lines, combined with quality control and traceability suitable for food, pharmaceutical and industrial customers. On request, we can support you with data sheets, test reports and documentation required by your QA or regulatory teams.

For international buyers, our sales and logistics team is familiar with ocean and air shipments to Europe, North America, Latin America, Oceania, the Middle East and Southeast Asia. We can coordinate packaging, palletizing and shipping details, so that your packaging film rolls arrive safely and are ready to run on your lines.