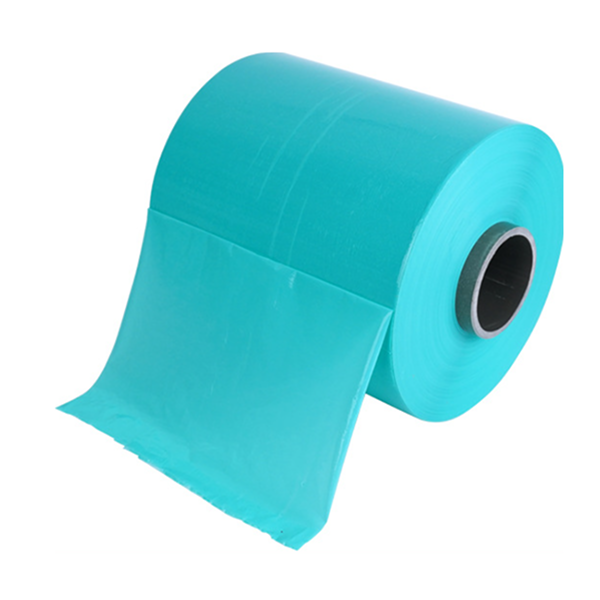

{ Transparent Polythene Roll }

Introduction: Tackling Your Packaging Challenges

Are you struggling to find a packaging material that both protects your products and showcases them clearly? Are you trying to balance cost, durability, and environmental responsibility? If so, you’re not alone. Many business owners and procurement managers face these challenges daily.

Transparent Polythene Roll is one of the most effective solutions to these problems. It’s a versatile, cost-efficient, and highly adaptable plastic film made from polyethylene (PE), supplied in a roll format for easy handling and automated processing.

In this guide, CloudFilm will walk you through everything you need to know about transparent polythene rolls—from their core benefits and key applications to how to choose the right specifications for your needs. By the end, you’ll be equipped to make an informed purchasing decision like a pro.

What Is Polyethylene (PE)? Understanding the Basics

Polyethylene, often abbreviated as PE, is the world’s most widely used plastic. It comes in several types, each with unique properties:

| Type | Full Name | Key Characteristics | Common Uses |

|---|---|---|---|

| LDPE | Low-Density Polyethylene | Soft, flexible, high clarity, easy to heat-seal | Food wrap, carrier bags, protective films |

| HDPE | High-Density Polyethylene | Rigid, strong, chemical-resistant | Heavy-duty sacks, industrial liners |

| LLDPE | Linear Low-Density Polyethylene | Excellent puncture & tear resistance, flexible | Stretch films, heavy-duty packaging bags |

At CloudFilm, we specialize in all three types and help you select the best one based on your application requirements.

Why Transparency Matters

The “transparent” feature of polythene rolls offers significant advantages:

- 🛍️ Product Visibility: Customers can see what they’re buying, enhancing trust and appeal.

- 📦 Inventory Management: Easily identify contents without opening packages.

- 🏷️ Brand Presentation: Showcases product quality and design.

- 🔍 Safety & Inspection: Allows for visual checks in food and pharmaceutical industries.

Why Choose Roll Format Over Pre-Made Bags?

Opting for film in roll form provides several operational benefits:

- 💰 Cost Efficiency: Lower cost per unit compared to pre-made bags.

- 🤖 Automation-Friendly: Compatible with automatic packaging and bagging machines.

- ✂️ Flexibility: Cut to any length as needed, adapting to various product sizes.

Industry Applications of Transparent Polythene Rolls

Transparent polythene rolls are used across many industries. Here’s a breakdown:

🍞 Food & Beverage

- Applications: Wrapping bread, vegetables, fruits; automatic packaging lines.

- Requirements: Food-grade certification, high clarity, anti-fog properties.

🧩 Industrial & Manufacturing

- Applications: Protecting parts, metal products from scratches and dust.

- Requirements: Puncture resistance, thickness durability.

📦 Logistics & Warehousing

- Applications: Pallet stretch wrapping, unitization of goods.

- Requirements: High tensile strength, dust and moisture protection.

🌱 Agriculture & Horticulture

- Applications: Greenhouse covers, silage films.

- Requirements: UV resistance, durability, controlled light transmission.

🛍️ Retail & E-commerce

- Applications: Packaging apparel, textiles, small goods.

- Requirements: Aesthetics, lightweight, protective.

How to Choose the Right Transparent Polythene Roll

{ How to Choose the Right Transparent Polythene Roll }

Here are the 5 key parameters to consider before purchasing:

1. Material Type

Refer to the PE table above to decide between LDPE, HDPE, or LLDPE based on flexibility and strength needs.

2. Thickness

Thickness is measured in microns (μm) or mils. Use the guide below:

| Thickness Range | Recommended Use |

|---|---|

| < 30 μm | Lightweight items |

| 30–80 μm | General-purpose packaging |

| > 80 μm | Heavy-duty/industrial applications |

3. Width & Length

Ensure the width matches your packaging machine and product size. Length determines how long the roll lasts.

4. Core Size

Common core diameters are 3 inches (76 mm). Make sure it fits your unwinding equipment.

5. Special Features

- Anti-static for electronics

- Anti-fog for fresh food

- UV-stabilized for outdoor use

- Printable for branding

At CloudFilm, our experts guide you through each of these parameters and offer free samples to ensure compatibility.

Why Choose CloudFilm?

{ Why Choose CloudFilm? }

🏆 Quality Assurance

- 100% virgin PE material

- Advanced extrusion technology

- Strict quality control

🎯 Customization Capability

- Tailored material, thickness, width, and features

- Fast turnaround for both small and bulk orders

🤝 Expert Support

- Dedicated technical consultation

- Free sample testing

- Reliable logistics and delivery

Conclusion & Next Steps

Transparent polythene rolls are a versatile, economical, and efficient packaging solution across industries. Selecting the right type and specifications is crucial to maximizing performance and cost-efficiency.

Ready to find the perfect transparent polythene roll for your business?

👉 Contact the CloudFilm team today for a personalized quote and free samples!