Reliable CPP Film Supplier in China – CloudFilm

CloudFilm supplies cast polypropylene (CPP) film rolls for converters and brands that need a soft, heat-sealable film with high clarity and good moisture resistance. Our CPP films are widely used as sealing layers in laminated structures for food, tissue, textile and stationery packaging, and can be tailored to your production lines.

Features:

-

Soft yet strong cast polypropylene structure for excellent sealing and machinability on VFFS/HFFS lines.

-

High clarity and gloss to keep products visible and attractive on the shelf.

-

Stable heat-seal performance with a wide sealing window for different packing speeds.

-

Optional anti-fog, anti-static, tissue and retort CPP grades to match each application.

-

Food-contact compliant materials with batch traceability and documentation on request.

- High-temperature resistance

CPP Film Series

CloudFilm offers a complete CPP film portfolio so you can cover most packaging jobs with one supplier. From general-purpose clear CPP film to metallized, anti-fog, anti-static, tissue and retort grades, all films are supplied in jumbo rolls, slit widths and customized roll diameters.

-

Clear CPP Film – general-purpose sealing film for mono-layer bags and laminates. Ideal as the sealing layer with BOPP or BOPET films.

-

Metallized CPP Film – high-barrier, metallic-look CPP film for snacks, tea, coffee and dry foods. Works well with BOPP and BOPET structures.

-

CPP Anti Fog Film – CPP film with anti-fog treatment for fresh produce, salad, bakery and chiller applications. Suitable for lidding and pillow packs.

-

CPP Anti Static Film – CPP film with controlled surface resistivity for electronics, dust-sensitive products and industrial components.

-

CPP Tissue Film – soft and quiet CPP film designed for facial tissue, toilet paper and napkin overwrap with excellent machinability.

-

Retort CPP Film – high-temperature-resistant CPP film for retort pouches and ready-to-eat meals, available for 121°C or higher processes depending on grade.

CPP films provide high clarity and surface gloss so that products remain clearly visible on the shelf. This is especially valuable when CPP is used as the outer sealing layer in laminated snack, bakery and tissue packaging.

CloudFilm’s CPP grades are designed for stable sealing on vertical and horizontal form-fill-seal lines, with adjustable hot-tack and heat-seal strength depending on the grade.

The soft cast polypropylene structure absorbs impact better than many oriented films, helping to prevent pinholes and damage during filling, transport and retail handling.

CPP films resist oils, fats and many chemicals commonly found in food and personal-care products. For higher-temperature processing, you can upgrade to our Retort CPP Film.

Why Choose CloudFilm's CPP Film for Your Packaging Business?

Designed for versatility and performance, our CPP films cater to various packaging applications. Embrace the benefits of our state-of-the-art technology, offering superior clarity, strength, and flexibility. Our approach is customer-centric, providing 24/7 support, rapid delivery from our vast warehouses, and the option for free samples to experience our quality firsthand. Choose CloudFilm for CPP Film solutions that blend innovation, reliability, and tailored service, enhancing your product’s appeal and your brand’s growth.

CPP Film Applications

Food Packaging

CPP film is widely used as the sealing layer for flow-wrap and pillow bags for candies, biscuits, bread, frozen foods and meat products. It can be laminated with BOPP film or BOPET film to add stiffness and barrier, helping your packs run smoothly on high-speed lines while keeping food fresh and visible.

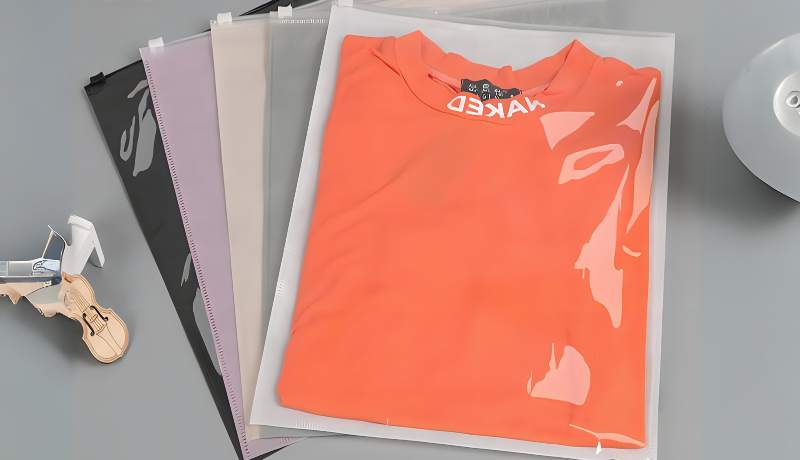

Textile Packaging

CPP film is used to make transparent bags for clothing, underwear, bedding sets and carpets. The film offers a soft hand-feel, good sealing and optional anti-static grades, helping to protect textiles from dust and moisture while maintaining a neat presentation.

Stationery and Office Supplies

CPP film is suitable for packaging folders, notebooks, book covers, calendars and other stationery items. Its clarity and smooth surface protect printed graphics from scratches and dust, while giving products a clean, premium look on the shelf.

Tissue Packaging

CPP film, especially our dedicated CPP tissue film, is widely used for facial tissue, toilet paper and napkin overwrap. It combines good transparency with smooth, quiet running on high-speed tissue lines, protecting the product from moisture and contamination while keeping branding clearly visible.

FAQ

Q1: What is CPP film and how is it different from BOPP film?

A1: CPP film (cast polypropylene film) is produced by casting molten polypropylene onto a chill roll, resulting in a softer, more flexible film with excellent sealing. BOPP film is biaxially oriented and therefore stiffer with higher tensile strength. In many laminates, BOPP provides stiffness and printability, while CPP is used as the inner sealing layer.

Q2: What CPP film types can CloudFilm supply?

A2: CloudFilm supplies several CPP grades, including Clear CPP Film, Metallized CPP Film, CPP Anti Fog Film, CPP Anti Static Film, CPP Tissue Film and Retort CPP Film. Each grade is described in detail on its own product page.

Q3: What is the typical thickness and width range of your CPP films?

A3: Most CPP grades are available from around 20–60 μm, with jumbo rolls up to about 2,000 mm wide and custom slit widths on request. For exact data, please refer to the technical data sheet on each CPP product page or share your target specification in the inquiry form.

Q4: Are CloudFilm CPP films suitable for food packaging?

A4: Yes. Our CPP films are produced from food-contact polypropylene resins and are widely used in food packaging. On request, we can provide relevant compliance statements and test reports to support your audits and customers’ requirements.

Q5: Do you offer retortable CPP film for high-temperature processing?

A5: Yes. CloudFilm’s Retort CPP Film is designed for high-temperature processes such as 121°C retort and ready-meal sterilization, depending on the specific grade. Please check the Retort CPP Film page or tell us your processing temperature and time so we can recommend a suitable film.

Q6: Can you customize slip, coefficient of friction and special functions such as anti-fog or anti-static?

A6: Yes. Many of our CPP grades can be tailored for slip level, COF, anti-fog performance, anti-static treatment and even perforation patterns. For example, CPP Anti Fog Film and CPP Anti Static Film are designed for these specific functions. Just describe your current structure and packing machine when sending an inquiry.

Q7: Are CPP films recyclable and can they be used in mono-material structures?

A7:CPP film is polypropylene-based and can be recycled in PP film streams where such recycling systems exist. However, “mono-material” in flexible packaging usually means that all layers are made from one polymer type, such as all-PP or all-PE.

CPP can be part of mono-PP structures when it is combined only with other PP films like BOPP or cast PP, which helps simplify sorting into PP recycling streams.

Q8: What is the minimum order quantity and sample policy for CPP film?

A8: The typical MOQ for CPP jumbo rolls is around 1,000 kg per grade and thickness. However, we are flexible for trial orders and new projects. Free A4 samples and short trial rolls are available so you can test performance before placing larger orders.

Q9: What is your normal lead time and shipping port for CPP films?

A9: For standard CPP grades, lead time is usually 2–4 weeks after order confirmation, depending on quantity and current production load. We mainly ship from Qingdao Port and can offer FOB, CIF and other terms according to your request.

Q10: Can CloudFilm help design the full laminate structure, not only CPP film?

A10: Yes. CloudFilm supplies BOPP film, BOPET film, PE film, high-barrier films and CPP films, and our engineers can help you design practical laminate structures for food, tissue, textile and industrial applications. Share your target application, current structure, thickness and machine type, and we will recommend suitable film combinations and provide a quotation.

Grow With CloudFilm’s CPP Film Solutions

Innovative Packaging Solutions with CPP Films

By combining CPP film with BOPP film, BOPET film, PE film and high-barrier films, CloudFilm helps you build practical laminate structures for snacks, dry foods, tissue, frozen food, textiles and more.

Our team can review your current structure, recommend alternative CPP-based designs and provide trial rolls so you can test performance on your existing lines.

Tailored to Meet Your Demands

Different packing lines and products require different film behavior. CloudFilm can adjust CPP film thickness, slip level, heat-seal strength, corona treatment and special functions such as anti-fog or anti-static to match your machines and end-use.

When you send an inquiry, simply share your application, target structure, film thickness and machine type, and we will recommend a suitable CPP grade.

Sustainability and Performance Combined

CPP film is polypropylene-based and can help you move away from complex PET/PA/AL laminates toward simpler PP-focused structures.

When CPP is combined only with other PP films such as BOPP, you can build mono-PP laminates that are easier to sort into PP recycling streams where available.