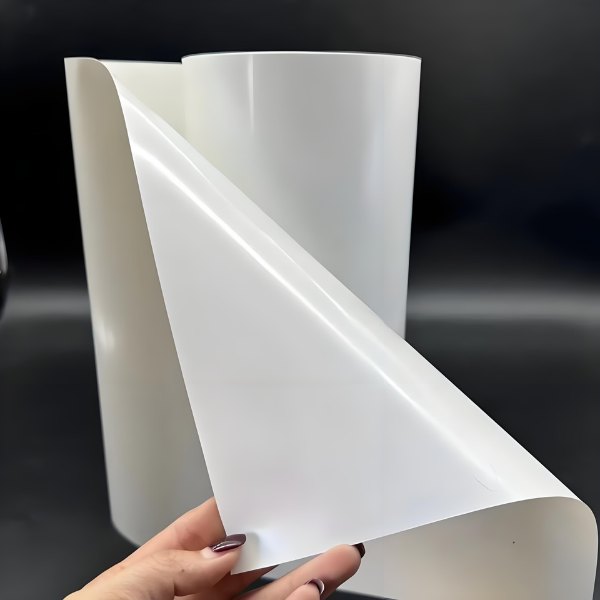

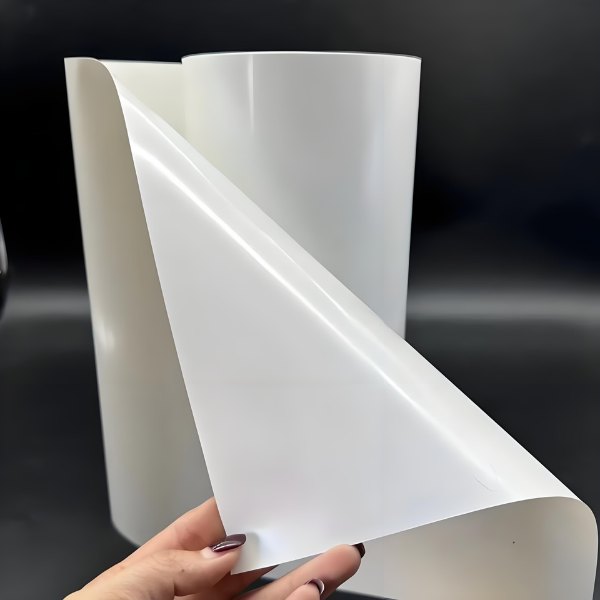

White PET Film

CloudFilm white PET film is an opaque, high-whiteness polyester film designed for premium labels, printing, electrical insulation and other industrial applications where light blocking and a clean white background are essential.

- High Opacity & Bright Whiteness – Delivers excellent light blocking and a brilliant white shade, ideal as a base film for labels, graphic panels and backlit prints.

- Stable & Durable Polyester Base – Biaxially oriented PET structure provides high tensile strength, temperature resistance and dimensional stability during printing, laminating and die-cutting.

- Optimized Print Surface – Smooth, uniform surface suitable for screen, digital and gravure printing, helping you achieve sharp images and consistent color.

- Customizable By CloudFilm – As a professional BOPET film supplier, CloudFilm can tailor thickness, width, corona treatment and functional coatings (anti-static, adhesive, etc.) to your process.

White PET Film Description

White PET film is an opaque, high-whiteness polyester film that combines excellent mechanical strength with a clean, printable surface. It is widely used by label converters, printing houses, electrical insulation manufacturers and industrial processors who need a stable white base instead of paper or PVC.

Depending on your application, CloudFilm can supply white PET film with glossy or matte finish, controlled opacity and one- or two-side corona treatment. Functional options such as anti-static coating, adhesive priming or hard-coat can be offered to enhance ink adhesion, scratch resistance or electrical performance.

For packaging and lamination projects, white PET can be used alone or combined with other substrates such as clear PET film rolls or PET/PE film to build multi-layer structures. Backed by CloudFilm’s technical team and more than 20 years of flexible film experience, you receive not only film rolls, but also guidance on structure design, processing window and cost optimization.

Get Free Sample of White PET Film

CloudFilm can provide trial rolls or sheets of white PET film tailored to your real application, so you can quickly verify print quality, opacity and processing performance before placing volume orders.

To receive a fast quotation and the right sample recommendation, please list the following information in your inquiry form:

-

Target application (for example: labels, inkjet printing media, electrical insulation, industrial tapes, release liners, etc.)

-

Required thickness (µm) and roll width (mm)

-

Surface treatment and coatings – one- or two-side corona, and whether you need anti-static, adhesive priming, hard-coat or other functional layers

-

Estimated monthly consumption or order quantity

-

Special standards or regulations that must be met (such as food-contact, flame-retardant grade, RoHS/REACH, low VOC, etc.)

-

Preferred delivery term and destination – for example FOB or CIF, and your destination port

Our team will use these details to propose a suitable grade, share processing suggestions.

White PET Film Application

1. Packaging & Labeling

White PET film is an excellent face stock or backing film for premium self-adhesive labels, wrap-around labels and high-value packaging. Its bright, opaque white shade helps brand graphics pop and can replace laminated paper in demanding environments. For over-lamination or alternative label constructions, it can be combined with films such as BOPP printing film.

2. Printing & Graphics

Thanks to its smooth, dimensionally stable surface, white PET film is widely used for indoor and outdoor signs, POP displays, menu boards and graphic overlays that require a durable white background. It can also serve as a complementary substrate to clear or holographic PET film in layered graphic structures.

3. Electrical Insulation

In electrical and electronic components, white PET film functions as an insulating layer in motors, transformers, coils and electronic assemblies where both dielectric strength and visual identification are important. It can be combined with other PET grades such as black PET film or anti-static PET film when special light-blocking or ESD protection is needed.

4. Industrial Applications

White PET film is also used as a base film for release liners, protective masking, adhesive tapes and composite laminates. When coated with silicone or other release systems, it can work together with PET release film solutions. For thermoforming or rigid packaging systems that require a matching white material, you can also consider APET film from CloudFilm.

FAQ

Yes. White PET film is fully recyclable as a polyester material, and our standard grades comply with RoHS and REACH regulations. If your project requires food-contact, low-VOC or other special certifications, please let us know so we can recommend the right structure.

In many cases, yes. White PET film offers good UV and weather resistance, especially when combined with suitable inks and protective laminates. For long-term outdoor signage, we recommend discussing exposure time, climate and lamination type with our team so we can suggest the most robust construction.

MOQ depends on thickness, width, coating type and whether we are running standard or specially developed grades. As a general reference, most export orders start from one full pallet or one production batch. Share your target specification and volume and we will confirm the MOQ and best logistics plan.

CloudFilm can offer multiple thicknesses suitable for label stock, printing media, insulation and industrial uses. Typical requests include thin films for labels and graphics and thicker films for electrical or mechanical applications.

Please indicate your required thickness (for example 25–75 µm), roll width and core size in your inquiry so we can match or design an appropriate grade.

Our white PET film is designed for high-quality printing and can be used with screen, UV flexo, gravure and some digital printing systems, provided the correct ink series and surface treatment are selected.

If needed, CloudFilm can supply corona-treated or top-coated grades to improve ink anchorage; share your printing process and we will recommend a suitable surface.

Compared with paper, white PET film offers much better tear resistance, water resistance and dimensional stability, making it ideal for durable labels and harsh environments. Versus white BOPP, PET generally provides higher stiffness, heat resistance and temperature stability. For applications where BOPP is also an option, you can refer to our article PET vs CPP/PET comparison and discuss the best choice with our team.

Yes. White PET film can be used as a backing for specialty adhesive tapes or as part of release liner constructions, especially when combined with silicone or other release coatings. CloudFilm also supplies dedicated PET release film grades if you need optimized release performance.

As a general guideline for PET films, we recommend storing rolls in the original packaging, in a clean, dry and cool indoor environment away from direct sunlight and high humidity.

Under proper storage conditions, white PET film is typically used within 12 months from production for best performance; for critical applications, please confirm specific storage and usage guidelines with our technical team.

Yes. White PET film can be laminated with other substrates such as PE, CPP or aluminum-coated films to build barrier or sealable structures. CloudFilm offers related products like PET/PE film and high-barrier PET VMPET PE structures discussed in our article on PET VMPET PE. Tell us your packaging requirements and we will propose a suitable structure.

To calculate roll weight or material yield, you need film density, thickness and dimensions. Our technical articles on PET film density and flexible film density formulas and yield explain the formulas and provide practical tables.

If you prefer, simply send us your target roll size and we can help you estimate weight and consumption.

Related News

Mylar Properties: A Practical Guide for Packaging and Industrial Uses “Mylar” is commonly used as a shorthand for biaxially […]

Introduction – Why Are PET and CPP Always Compared? 1.1 Setting the Scene: The “Century-Old Dilemma” of Packaging […]

In the world of engineering, manufacturing, and product design, precision is paramount. When working with materials like PET (Polyethylene […]

Introduction If you’re a product manager, packaging engineer, or procurement specialist researching high-performance packaging solutions, your search has […]

Introduction: What is Mylar PET? Mylar PET is a high-performance polyester film that plays a crucial role […]

Why PET ALOx Matters For Modern Packaging In food, pharmaceutical and technical packaging, buyers are under pressure to […]

Introduction In today’s fast-paced food industry, flexible food packaging has become a game-changer. It offers lightweight, customizable, and sustainable […]

Introduction In today’s competitive market, custom flexible packaging has become a cornerstone of branding, logistics, and sustainability. Whether you’re […]