IML Film Order Process With CloudFilm

From first idea to full-container shipment, we support every step of your IML project.

Step 1 – Share your project requirements

Tell us about your application (yogurt cups, ice cream containers, buckets, household items, etc.), molding process, resin type and target markets. If available, please also share drawings or photos of your containers.

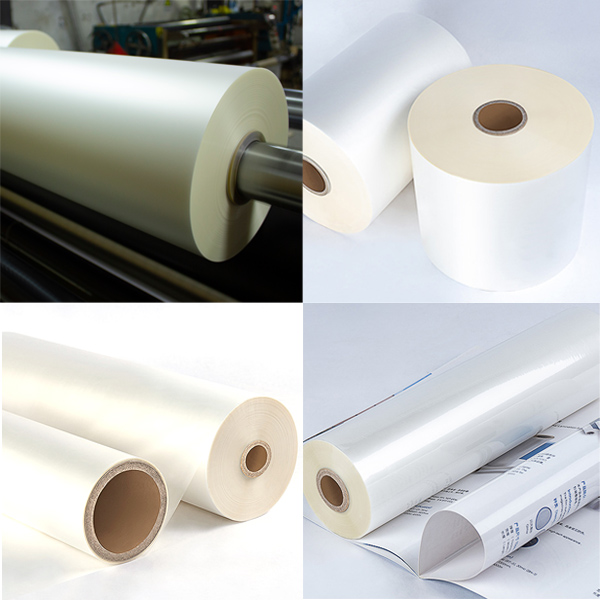

Step 2 – Film recommendation & sample rolls

Based on your information, our technical team will recommend a suitable IML film structure (white / opaque / transparent, thickness range, surface treatment). We can prepare trial rolls for printing and molding tests.

Step 3 – Printing and molding trial support

Your IML label converter prints the labels, and your molder tests them on the injection or blow molding line. During this stage we can fine-tune corona level, slip and other parameters to ensure stable production.

Step 4 – Final specification & quotation

After successful trials, we confirm the final specification and provide a detailed quotation, including MOQ, lead time and packing details. If you also need flexible packaging for the same design, we can coordinate IML film and flexible pouches in one project.

Step 5 – Mass production & quality control

IML film is produced on our BOPP lines with strict quality checks for thickness profile, surface appearance, winding quality and corona level. Each batch is traceable and supplied with a COA.

Step 6 – Export packing, shipping & after-sales service

Rolls are packed on pallets with moisture and edge protection suitable for sea freight. We arrange shipping to your requested port and keep you updated. After you start regular production, our team is available for continuous technical support and optimization.