Ordering & Customization Checklist for BOPP Holographic Film

To prepare a precise quotation and technical recommendation, please share as much of the following as you can:

-

End application (e.g., snack wrap, cigarette soft pack, cosmetic carton, gift wrap, security label).

-

Structure and process (surface printing, reverse printing + lamination, cold / thermal lamination).

-

Required thickness (e.g., 23 / 30 / 35 µm) and film type (transparent or metallized).

-

Holographic pattern and color (standard rainbow, dots, lens, or custom logo / artwork).

-

Roll specifications (width, target roll diameter or roll weight, 3″ or 6″ core).

-

Annual or monthly consumption and required certifications (e.g., food-contact, RoHS, REACH).

CloudFilm can then propose a suitable holographic BOPP grade, send trial rolls, and optimize the roll configuration for your packing and printing lines.

Not sure about all the technical details?

If you are new to holographic films or not familiar with these parameters, that is completely fine. You can still send us an enquiry by simply telling us:

-

What you are packing (for example: potato chips, chocolate, cigarettes, cosmetics, gift box, etc.);

-

How the package looks today (a brief description or photos of your existing packaging);

-

Any basic size you know (approximate width, film thickness, or pack size, if available);

-

Your country and preferred delivery term (FOB / CIF and destination port).

Our technical team will fill in the missing details, suggest a suitable structure and thickness, and guide you step by step. Even if you only know “I want a holographic film similar to the sample in the photo”, you are very welcome to contact CloudFilm.

How to Choose Between BOPP and PET Holographic Film

Choose BOPP holographic film when:

- You need flexible, cost-effective film for snack, confectionery, tobacco, or general consumer goods packaging.

- Good moisture barrier, stiffness, and machinability are more important than very high heat resistance.

- You aim to design PP-based mono-material packaging for recyclability.

Choose PET holographic film when:

- You require higher heat resistance and dimensional stability (e.g., high-temperature processes, more demanding lamination).

- You want extra stiffness and sharper holographic images for premium cartons, cards, and high-value labels.

- The structure is PET-based (BOPET) and needs strong mechanical and optical performance.

For projects where you are unsure which to choose, share your application, process temperature, and current structure with CloudFilm. Our team can recommend BOPP or PET holographic film and the right thickness for your line.

Illuminating the Market with BOPP Holographic Film: A Vision of Innovation

Elevating Packaging to a New Dimension of Attraction

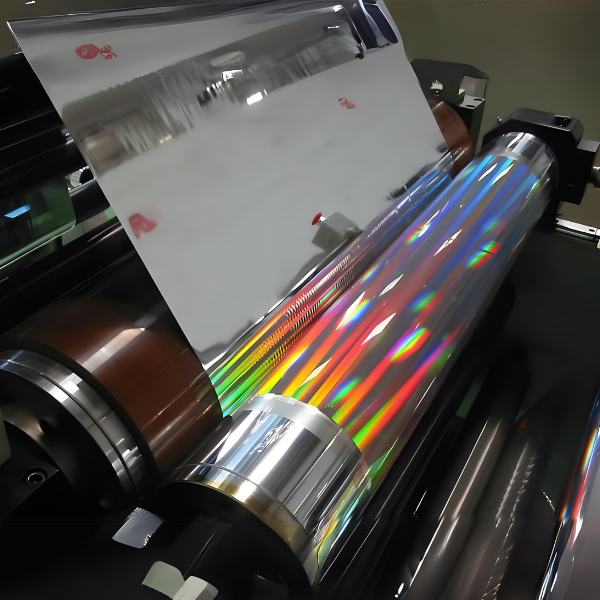

In crowded retail aisles, packaging needs more than just good printing. CloudFilm’s BOPP holographic film turns standard packs into moving light displays, combining strong BOPP mechanical properties with high-impact optical effects.

By choosing transparent or metallized holographic BOPP, you can fine-tune opacity, barrier performance, and visual strength for each SKU. The film runs reliably on common printing, lamination, and packing lines, helping you upgrade visual appeal without redesigning your whole process.

Mastery Behind the Magic: CloudFilm’s Excellence in Holographic Innovation

CloudFilm has invested in dedicated holographic embossing and metallizing equipment, allowing us to supply consistent holographic BOPP film rolls in industrial quantities. Our team can recommend patterns and structures based on your application—whether you need a subtle shimmer for cosmetics or a bold rainbow effect for holiday promotions.

From sampling to mass production, we support you with technical data, trial rolls, and flexible roll specifications. As your holographic film partner, CloudFilm helps you balance design impact, line efficiency, and total packaging cost.