What “Digital Flexible Packaging” Really Means

When people say “digital packaging,” they often think digital printing only. In reality, digital flexible packaging is a connected workflow that uses:

- Digital prepress (no cylinders/plates for many jobs)

- Digital print (electrophotography or inkjet)

- Digitally enabled finishing (laser scoring, variable data, agile lamination)

- Data-driven planning for SKU proliferation, seasonal versions, and targeted launches

The result: short-to-mid runs with fast cycle times, on-brand color, and the option to add smart, traceable features—without committing to analog MOQs or long lead times.

Why Brands Are Moving Now (Benefits & Use Cases)

a) Speed to market. Launch new SKUs in days, not months.

b) MOQ reduction. Prove demand with micro-batches; scale once validated.

c) Versioning & localization. Multiple languages or seasonal art in one run.

d) Waste reduction. Print only what you need; lower inventory obsolescence.

e) Revenue experiments. Limited editions, influencer drops, market A/B tests.

f) Sustainability alignment. Lighter packs; potential mono-material structures for better end-of-life sorting.

Use cases: DTC snacks, specialty coffee, nutraceuticals, pet treats, cosmetics, home-care refills, frozen & chilled meals (with suitable lidding and anti-fog), and trial sizes for retail buyers.

Core Technologies: Digital Printing, Prepress & Finishing

- Digital print engines:

- Electrophotography (e.g., liquid toner)—excellent registration and fine text.

- UV/Water-based Inkjet—high opacity whites, fast turnarounds, broad substrates.

- Prepress: No cylinder engraving; fast color iterations; PDF workflows.

- Finishing:

- Laser scoring/tear lines for easy-open sachets/stick packs.

- Variable data (unique QR codes, serialized promotions).

- Protective OPV/thermal lamination tailored to rub resistance and migration limits.

- Color management: Digital presses can emulate brand Pantones using expanded gamut and on-press profiling—critical for multi-SKU lines.

Pack Formats and How Digital Helps

Stand-Up Pouches (SUP)

- Great billboard area for brand storytelling.

- Digital supports many micro-variants (flavors/sizes) in one consolidated job.

- For recyclability, lean toward mono-PE or mono-PP designs where performance allows.

Related internal resource: Explore recyclable mono-material pouches for sustainable, brandable formats.

recyclable mono-material pouches

Spout Pouches (Refills, beverages)

- Digital white + vivid CMYK for high shelf pop on clear or metallized webs.

- Reinforced spout areas require well-chosen structures and sealing windows.

Lidding Films (Trays, cups, bowls)

- Control peel strength, anti-fog, and seal compatibility (PP, PET, PE trays).

- Digital enables brand updates across many SKUs without new plates.

Learn more in our lidding film guide for material and sealing tips.

lidding film guide

Flow Wrap (Pillow Packs)

- Snack bars, confectionery, bakery. Digital helps rapid flavor rotations.

- Requires stable COF and tight thickness control for wrinkle-free wraps.

Sachets & Stick Packs

- Excellent for samples/portion packs.

- Laser scoring + VDP turns sachets into scannable, traceable assets.

See our quick flexible packaging solutions overview for converting considerations across each format.

flexible packaging solutions overview

Film & Structure Choices for Digital (and for Recycling)

Match structure to product + process:

- PE (BOPE/MDO-PE) routes for mono-material recyclability; good sealability.

- PP (CPP/CPO/BOOP) for stiffness, clarity; mono-PP structures for some dry foods.

- PET (with or without ALOx for transparent barrier) for high stiffness and print clarity.

- Seal layers: CPP/PE blends; anti-fog for chilled produce; peelable systems for lidding.

- Barrier: EVOH, ALOx PET, or coatings—balance cost, OTR/WVTR, and recyclability targets.

Artwork, Data & Smart Packaging

- VDP (Variable Data Printing): Unique QR per pouch: loyalty, authenticity, or recalls.

- Lot/Date coding: Inline or digitally imposed in artwork.

- Accessibility & UX: High-contrast nutrition tables, easy-open notches/scoring, tactile marks.

- Anti-counterfeit: Serialized IDs + encrypted redirect; microtexts on digital presses.

- Regulatory text layers: Keep claims in editable layers for quick legal updates.

Cost & Lead Time: Where Digital Wins vs. Analog

- No plates/cylinders: Save thousands on very short runs.

- Breakeven: Digital dominates at low–mid volumes or with heavy versioning.

- Inventory economics: Less cash trapped in packaging; lower write-offs when recipes change.

- Time: Prepress to ship in days; analog lines tie up with engraving, approvals, and makeready.

Quality, Food Contact & Compliance Notes

- Ink/OPV selection: Match migration limits and heat resistance for the product/process.

- Color/registration: Digital excels at small type and gradients; use on-press profiling.

- Lamination & curing: Ensure bond strength and full cure before pouch-making/filling.

- Sealing windows: Define SIT/hot-tack for your filler; dial in anti-fog for chilled lines.

- Traceability: Keep substrate/ink/lamination batch logs per lot; pair with QR IDs.

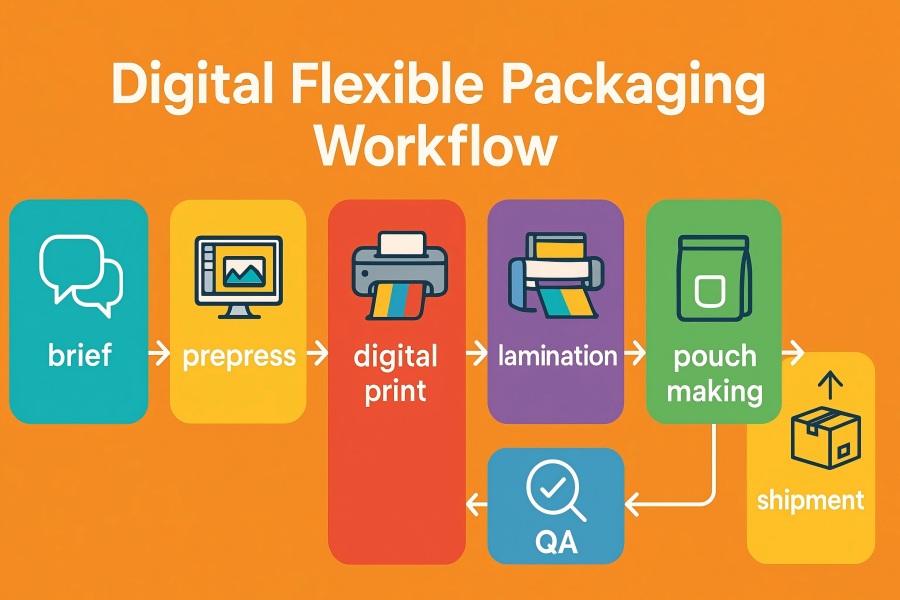

Implementation Roadmap (From Brief to Shelf)

- Define product risks & channels (e-commerce vs. retail, chilled vs. ambient).

- Choose pack format (SUP, spout, lidding, flow wrap, sachet).

- Select structure (mono-PE or mono-PP where feasible; PET/ALOx for clear high barrier).

- Artwork & VDP plan (SKUs, languages, QR logic, promotions).

- Press proof & color target (brand hues, spot emulation).

- Pilot run (functional tests: seal, drop, burst, OTR/WVTR as applicable).

- Scale-up (lock spec; schedule rolling micro-batches to avoid obsolescence).

- Recycle-readiness review (claims aligned with your market’s infrastructure).

- Ongoing optimization (collect scan data; tune variant volumes).

FAQs

Q1: What minimums can digital handle?

Short runs from hundreds to a few thousand units are practical; digital scales well to mid volumes when versioning is heavy.

Q2: Can I use recyclable structures with digital?

Yes—mono-PE/mono-PP designs pair well with digital inks/OPVs when specified correctly. See our recyclable pouch options for reference.

recyclable mono-material pouches

Q3: What about ready-meals and chilled foods?

Choose anti-fog lidding films tuned to your tray polymer (PP, PET, PE) and target peel strength.

Q4: Which pack formats are best for limited editions?

SUP and flow wrap excel for seasonal art and rapid flavor cycles. For an overview, see our flexible packaging solutions page.

flexible packaging solutions overview

Gentle CTA

Have a concept, a trial run, or a regional launch? We’ll help you pick a recyclable structure, dial in print/lamination, and deliver retail-ready pouches fast.