Introduction

Packaging plays a crucial role in product protection, brand presentation, and consumer experience. In today’s competitive market, choosing the right packaging type can significantly impact your product’s success. Flexible and rigid packaging represent two distinct approaches, each with unique advantages and applications.

This comprehensive guide will help you understand these packaging types and make informed decisions for your specific needs.

Flexible Packaging Explained

1.1 Definition and Characteristics

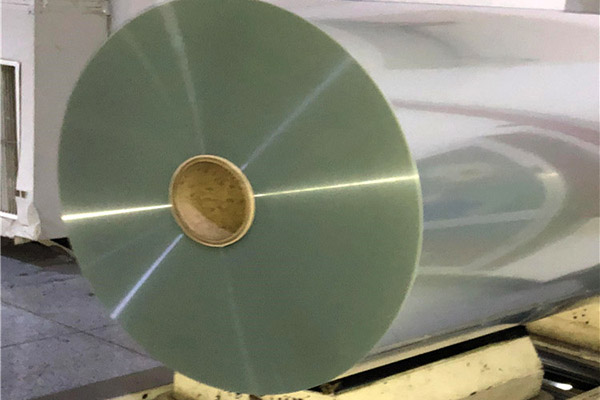

Flexible packaging refers to packages made of flexible materials that can change shape when filled or during use. These packages typically include plastic films, aluminum foil, and paper laminates.

1.2 Common Types

- Plastic bags and pouches

- Aluminum foil pouches

- Flexible tubes

- Wrapping films

- Stand-up pouches

1.3 Advantages

- Lightweight and portable

- Space-efficient storage and transportation

- Cost-effective production

- Customizable printing options

- Extended shelf life with barrier properties

1.4 Limitations

- Limited protection for fragile items

- Less premium feel compared to rigid packaging

- Potential environmental concerns

1.5 Typical Applications

Flexible packaging is commonly used for food products, personal care items, pharmaceuticals, and pet food.

Rigid Packaging Explained

2.1 Definition and Characteristics

Rigid packaging maintains its shape regardless of contents, offering superior protection and a premium feel.

2.2 Common Types

- Glass bottles and jars

- Metal cans

- Rigid plastic containers

- Cardboard boxes

- Composite cans

2.3 Advantages

- Excellent product protection

- Premium brand image

- Reusable and recyclable options

- Better stackability

- Longer shelf life for certain products

2.4 Limitations

- Heavier weight increases shipping costs

- Requires more storage space

- Generally higher production costs

- Potential for breakage (glass)

2.5 Typical Applications

Rigid packaging is ideal for beverages, cosmetics, electronics, luxury goods, and products requiring maximum protection.

Direct Comparison: Flexible vs Rigid Packaging

Let’s compare these packaging types across key factors:

| Factor | Flexible Packaging | Rigid Packaging |

|---|---|---|

| Protection Level | Moderate to Good | Excellent |

| Cost | Lower | Higher |

| Weight | Lightweight | Heavy |

| Storage Space | Efficient | Requires More Space |

| Environmental Impact | Mixed (less material but harder to recycle) | Mixed (more material but often easier to recycle) |

| Brand Perception | Practical | Premium |

| Customization | High | Moderate |

| Consumer Convenience | High | Moderate |

Industry Trends and Market Analysis

The packaging industry is experiencing significant shifts driven by consumer preferences and sustainability concerns. Flexible packaging currently holds approximately 40% of the global packaging market, with rigid packaging comprising the remaining 60%. However, flexible packaging is growing at a faster rate (CAGR of 4.5%) compared to rigid packaging (CAGR of 3.2%).

4.1 Key trends include:

- Sustainable materials and biodegradable options

- Smart packaging with QR codes and NFC technology

- Minimalist design approaches

- Convenience features like resealable closures

How to Choose the Right Packaging Type

5.1 Product Considerations

Evaluate your product’s characteristics:

- Fragility and protection needs

- Shelf life requirements

- Chemical compatibility

- Weight and size

5.2 Target Audience Analysis

Consider your consumers’ preferences:

- Demographics and lifestyle

- Usage patterns

- Environmental consciousness

- Convenience expectations

5.3 Budget and Cost Factors

- Production costs

- Shipping and logistics expenses

- Storage requirements

- Return on investment

Hybrid Packaging Solutions

Many innovative companies are combining flexible and rigid packaging elements to create optimal solutions. For example, rigid containers with flexible lids, or flexible pouches with rigid spouts and caps.

At CloudFilm, we specialize in developing customized hybrid packaging solutions that leverage the best of both worlds. Our innovative approach ensures your products stand out while meeting functional requirements.

Conclusion

Both flexible and rigid packaging offer unique advantages and serve different market needs. The choice between them depends on your specific product requirements, target audience, budget constraints, and brand positioning.

As the packaging industry continues to evolve, staying informed about new materials, technologies, and consumer preferences will help you make the best packaging decisions for your products.

FAQs

Q: Which packaging type is more environmentally friendly?

A: Both have environmental pros and cons. Flexible packaging uses less material but is harder to recycle. Rigid packaging uses more material but is often easier to recycle and reuse. The most eco-friendly choice depends on your specific product and local recycling infrastructure.

Q: How can I reduce packaging costs without compromising quality?

A: Consider hybrid solutions, optimize package dimensions, explore alternative materials, and work with experienced packaging partners like CloudFilm who can suggest cost-effective alternatives.

Q: What packaging innovations should I watch for in the coming years?

A: Keep an eye on biodegradable materials, smart packaging with integrated technology, edible packaging, and designs that minimize material usage while maximizing protection.

Q: How does CloudFilm help companies choose the right packaging?

A: At CloudFilm, we provide comprehensive packaging consultations, material testing, prototyping services, and production support. Our team analyzes your specific needs and recommends optimal solutions that balance functionality, cost, and sustainability.