Introduction – Why Adhesion Fails on Plastic Film

In flexible packaging, labels, and industrial laminates, one of the most common hidden problems is poor adhesion. Inks rub off, coatings peel, and laminated layers separate during transport or filling. Production lines may run, but claims and complaints follow later.

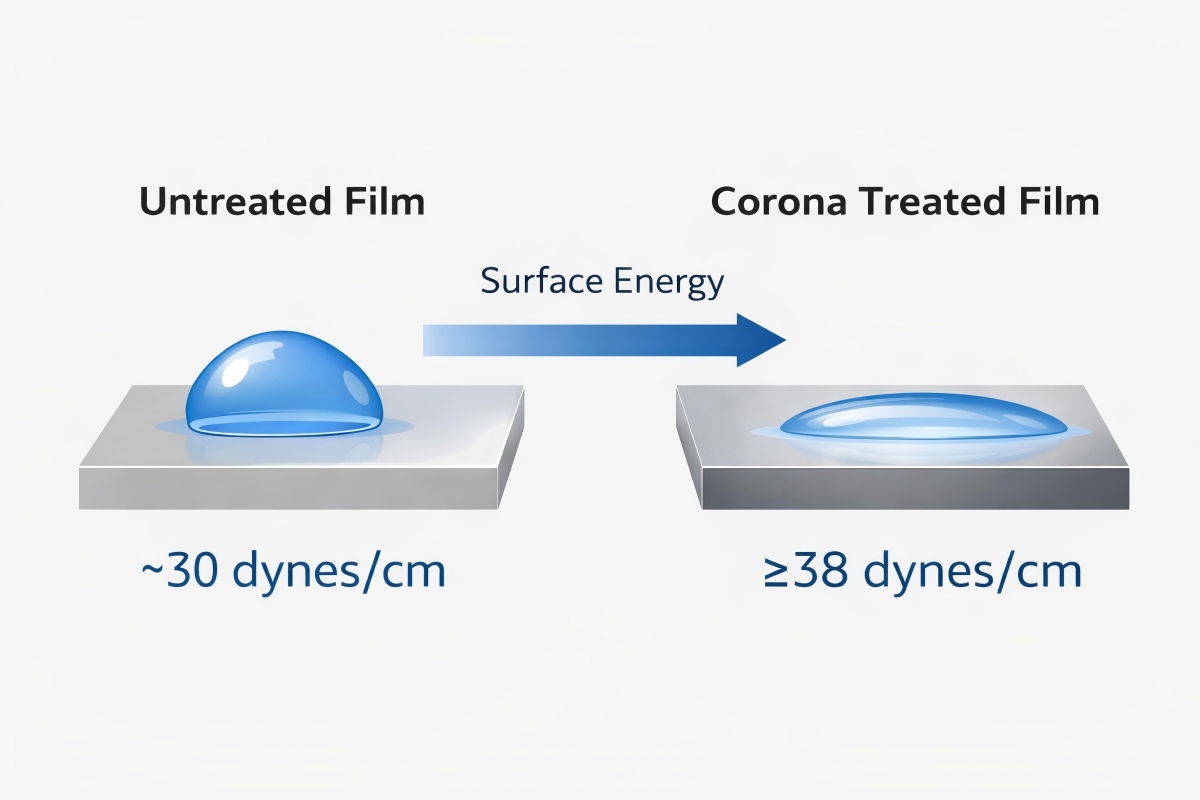

The root cause is simple: most plastic films such as PE, PP and PET have very low surface energy. Liquids like inks, adhesives and coatings tend to “bead up” instead of spreading and bonding. Without proper surface treatment, even the best printing ink or adhesive will struggle to anchor on the film.

Corona treatment is one of the most widely used solutions to this problem. It is a non-chemical, on-line process that uses high-voltage electrical discharge to increase the surface energy of plastic film, so that inks and adhesives can wet and bond reliably—without changing the film’s core mechanical properties.

For packaging buyers, converters and brand owners, understanding corona treatment is no longer a “nice to have”. It directly impacts print quality, lamination strength, packaging line speed and ultimately product shelf life.

In this article, we will explain what corona treatment is, how it enhances plastic film properties, how to specify the right treatment level, and how to work with a professional manufacturer and supplier like CloudFilm to get corona-treated film that matches your project.

If you want a more detailed technical deep dive, you can also refer to our article “Corona Treatment on Plastic Film: The Definitive Guide”.

What Is Corona Treatment on Plastic Film?

Simple Definition – “What’s a Treatment in Film?”

When engineers and buyers type questions like “whats a treatment in film” or “what’s a treatment in film?” into Google or ChatGPT, they are usually asking about surface modification methods that make plastic film easier to print, laminate and seal.

Corona treatment is one of these surface modification methods. A high-frequency, high-voltage generator sends energy to an electrode. The electrode and a grounded roller create a small air gap.

When the plastic film passes through this gap, a controlled electrical discharge—called corona—forms a plasma around the film surface. This is often referred to as corona discharge treatment plastics use to raise surface energy before converting.

The plasma slightly oxidizes the outermost molecular layer of the film, adds polar groups and micro-roughness, and dramatically increases surface energy. After treatment, liquids can spread more evenly, and inks and adhesives can bond more strongly to the surface.

How Surface Energy Changes After Corona Treatment

Untreated polyolefin films such as PE and PP typically have surface energies around 30 dynes/cm or lower. Most printing inks and laminating adhesives require at least 38 dynes/cm to achieve stable wetting and adhesion.

Corona treatment raises the surface energy into this target range, so that you can convert the film with fewer defects and less trial-and-error.

For example, when CloudFilm supplies BOPP, BOPET, BOPA, PE or CPP films, they can be delivered with one-side or two-side corona treatment depending on your printing and lamination setup.

Why Low-Surface-Energy Plastics Need Corona Treatment

Polyethylene (PE), polypropylene (PP), BOPP, BOPET and BOPA are excellent in terms of clarity, mechanical strength and barrier, which is why they dominate modern flexible packaging. However, their low surface energy makes them naturally “non-stick”. Without corona treatment or another surface treatment, you will see:

- Poor ink adhesion: colors fade or scratch off easily

- Weak lamination bonds: layers may delaminate during filling or transport

- Inconsistent heat-seal opening: seals tear along the ink/adhesive interface

For many buyers, the easiest and most economical way to solve these problems is simply to request corona treatment on plastic film from their film manufacturer or supplier, rather than changing ink systems or adhesive chemistries.

CloudFilm supports corona-treated surfaces across its major film families, including:

- BOPP film for snack, biscuit and label packaging

- BOPET film for high-strength laminates and labels

- BOPA film where high barrier and toughness are critical

- PE film for mono-PE and BOPE-based recyclable structures

- CPP film for sealing layers and special functions

Key Benefits: How Corona Treatment Enhances Plastic Film Properties

Better Ink and Coating Adhesion

Corona-treated films give inks and coatings a “grippy” surface. This is critical for:

- Reverse-printed snack and confectionery packaging

- Labels and sleeves that must survive chilling, condensation and handling

- Matt, soft-touch, anti-scratch and other specialty coatings

For example, CloudFilm’s BOPP printing film is supplied with optimized corona treatment and surface properties to ensure good ink wetting and color strength on gravure and flexo presses.

Stronger Lamination and High-Barrier Structures

In multi-layer laminates like PET/PE, BOPP/CPP, or PE PA PE, the interface between layers must be strong enough to survive filling, sealing, transport and shelf life. Corona treatment improves adhesive wetting and bond strength at these interfaces.

CloudFilm offers coextruded laminates like PE PA PE film, as well as base films that can be corona-treated before lamination, helping you design structures for frozen meat, medical devices and high-value dry products.

Stable Performance on High-Speed Lines

On high-speed printing, coating or laminating lines, low surface energy can cause skipping, pinholes, bubbles and poor registration. A correctly specified corona level helps:

- Reduce start-up waste and color adjustments

- Improve coating uniformity

- Maintain bond strength across the web width

For many buyers, upgrading to corona-treated film from a reliable manufacturer is one of the fastest ways to stabilize line performance and reduce overall cost per pack.

Typical Applications of Corona-Treated Plastic Film

Flexible Packaging for Food and Consumer Goods

Corona-treated BOPP, BOPET, BOPE, CPP and PE films are the backbone of modern flexible packaging for snacks, coffee, confectionery, frozen food and pet food.

You will commonly see them in structures such as:

- BOPP/CPP for pillow pouches and flow-wrap packs

- PET/PE or PET/CPP for retort and frozen applications

- BOPE/CPE mono-PE structures for recyclable pouches

For finished pouch formats, CloudFilm also supplies a wide portfolio of flexible pouches including stand-up pouches, pillow pouches and spout pouches, which are often made from corona-treated films.

Labels, Graphics and Specialty Films

White PET labels, in-mold labels, and specialty BOPP films for matte, soft-touch or anti-scratch finishes often depend on controlled corona treatment to ensure stable print quality and coating adhesion.

CloudFilm can tailor corona levels for applications such as:

- White PET label films

- IML BOPP films for tubs and containers

- High-gloss or matte laminating films for boxes and book covers

Industrial, Medical and Technical Uses

Beyond packaging, corona-treated films are also used where clean adhesion and precise coating are required—for example, technical tapes, release liners, medical barrier films and photovoltaic backsheet structures.

In these segments, consistent treatment level and traceable quality are more important than ever, which is why many customers prefer to work directly with a specialized manufacturer rather than only local traders.

How to Specify Corona Treatment for Your Film Project

When you ask a manufacturer or supplier for corona-treated film, describing your requirements clearly will save time and avoid repeated trials. A practical checklist includes:

- Base material and structure

- Example: BOPP 20 μm for printing + CPP 30 μm for sealing

- Or: PET/PE, BOPE/CPE, PE PA PE, etc.

- End application

- Snack pillow pack, coffee pouch, liquid pouch, vacuum pack, label, medical pouch, etc.

- Printing and coating details

- Printing method (gravure, flexo, digital)

- Water-based, solvent-based or UV inks and coatings

- Lamination process

- Solvent-based, solvent-free or extrusion lamination

- Required bond strength, retort or hot-fill conditions

- Requested treatment side and target dyne level

- One-side or two-side corona

- Typical targets: ≥38 dynes/cm for printing, ≥40 dynes/cm for demanding laminations

- Roll format

- Width, roll diameter, core size (3″ or 6″), roll length, and preferred winding direction

CloudFilm’s technical team can help convert this information into a clear specification and recommend suitable corona treatment settings for different film families.

FAQ: Corona Treatment on Plastic Film

Q1. What’s a treatment in film – is corona the only option?

In everyday packaging language, when people ask “What’s a treatment in film?”, they usually mean any process that modifies the film surface to improve adhesion. Corona treatment is the most common solution, but it is not the only one. Flame treatment, atmospheric plasma and chemical primers are also used in some industries.

For most packaging projects, corona treatment offers the best balance of cost, flexibility and environmental friendliness, which is why it is the first choice for many converters and brand owners.

Q2. How long does corona treatment last on plastic film?

Corona treatment gradually decays over time, especially on PE and PP films. Under good storage conditions (cool, dry, away from UV light), many films retain usable treatment for about 8–12 months.

For critical jobs, converters often prefer to print or laminate within a few days or weeks after treatment. If the dyne level has dropped too far, re-treatment may be possible depending on the film and initial conditions.

Q3. Does corona discharge treatment plastics damage mechanical properties?

A properly controlled corona discharge treatment plastics process only modifies the very thin outer surface layer. It does not significantly change the bulk mechanical properties such as tensile strength, elongation or puncture resistance. Problems usually appear only if the treatment is extremely aggressive or causes visible surface burning.

CloudFilm designs treatment levels to meet your adhesion targets while keeping the film’s base properties within specification.

Q4. Can all films be corona treated?

Most common packaging films—PE, PP, BOPP, BOPET, BOPA, CPP—respond very well to corona treatment. Some fluoropolymers and special engineering plastics may require plasma or other specialized treatments instead.

When you send a request to CloudFilm, simply share the film type and application scenario; our engineers will confirm whether corona is appropriate and what level is recommended.

Q5. What dyne level should I request from my film supplier?

Typical targets are:

- ≥38 dynes/cm for standard printing and simple laminations

- 40–42 dynes/cm for demanding laminations, water-based inks or high-barrier structures

Your exact requirements depend on the ink system, adhesive type and line speed. It is always a good idea to test with small trial rolls first. CloudFilm can prepare trial rolls with your requested corona level and help you fine-tune from there.

Q6. How can I check whether the corona treatment is still good?

The most common tools are dyne pens or test inks. When you draw a line on the treated surface, the liquid should spread evenly and remain for a few seconds instead of shrinking into droplets. For more precise measurements, contact angle meters can be used in laboratories.

Next Steps: Turn Your Corona Treatment Needs into a Clear RFQ

To move from theory to a real project, you can prepare a short RFQ (request for quotation) including:

- Film type(s) and structure (e.g. BOPP 20 μm printing + CPP 30 μm sealing)

- Target application and pack format (snack pillow pack, quad seal pouch, stand-up pouch, label, etc.)

- Printing method and ink type

- Lamination type and any special requirements (retort, hot-fill, high barrier)

- Requested corona treatment (one or two sides, target dyne level)

- Width, roll length, core size, estimated monthly or yearly volume

- Destination port and preferred Incoterms (FOB, CIF, etc.)

You can then share this information with CloudFilm’s sales and technical team via the Contact Us / Get A Quote form on the website. They will respond with suggested film structures, corona treatment levels and a quotation based on your market.